Food additive production heating device

A technology of food additives and heating devices, applied in heating devices, lighting and heating equipment, drying, etc., can solve the problems of poor flexibility, low reliability, and low production efficiency, and achieve flexible use and high reliability , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

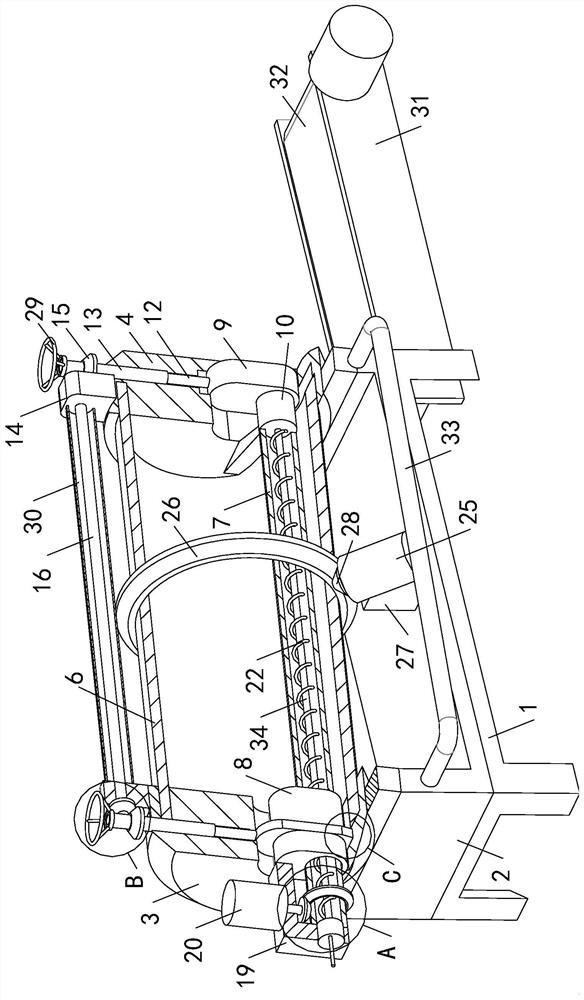

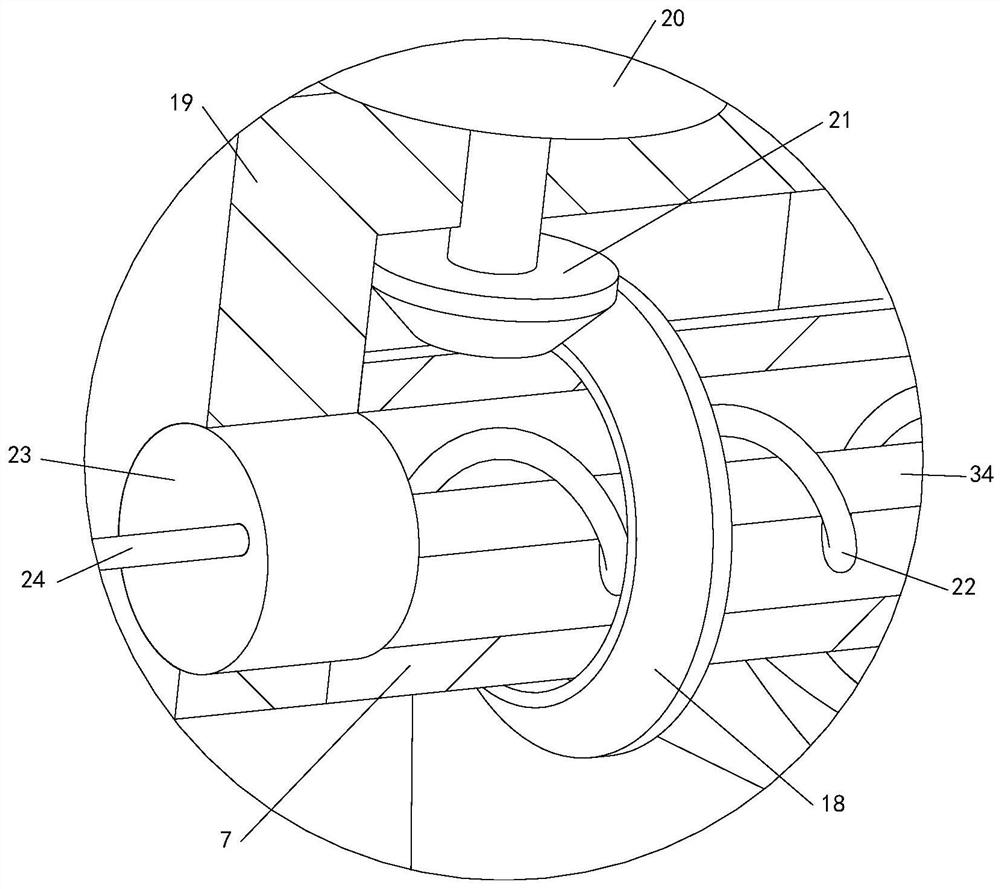

[0029] See Figure 1-5 A food additive produces a heating device, including mounting frame 1, further comprising a bracket 2, a bracket 2, and a mounting frame, and a left end frame 3 and a right end frame 4 are fixed, and the left end frame 3 is connected. There is a feed bucket 5, the right end frame 4 is opened, and the left end frame 3 and the right end frame 4 are rotated between the drying cylinder 6, facilitate the mating of the roller 7 to realize the raw material of the food additive, using reliability High, the drying cylinder 6 is mounted between the drying cylinder 6, facilitating the driving of the drying cylinder 6, and facilitates the adjustment of the relative rotational speed of the roller 7 and the drying cylinder 6, thereby facilitating the adjustment of the production speed according to the type of food additive. High production efficiency, more flexible use.

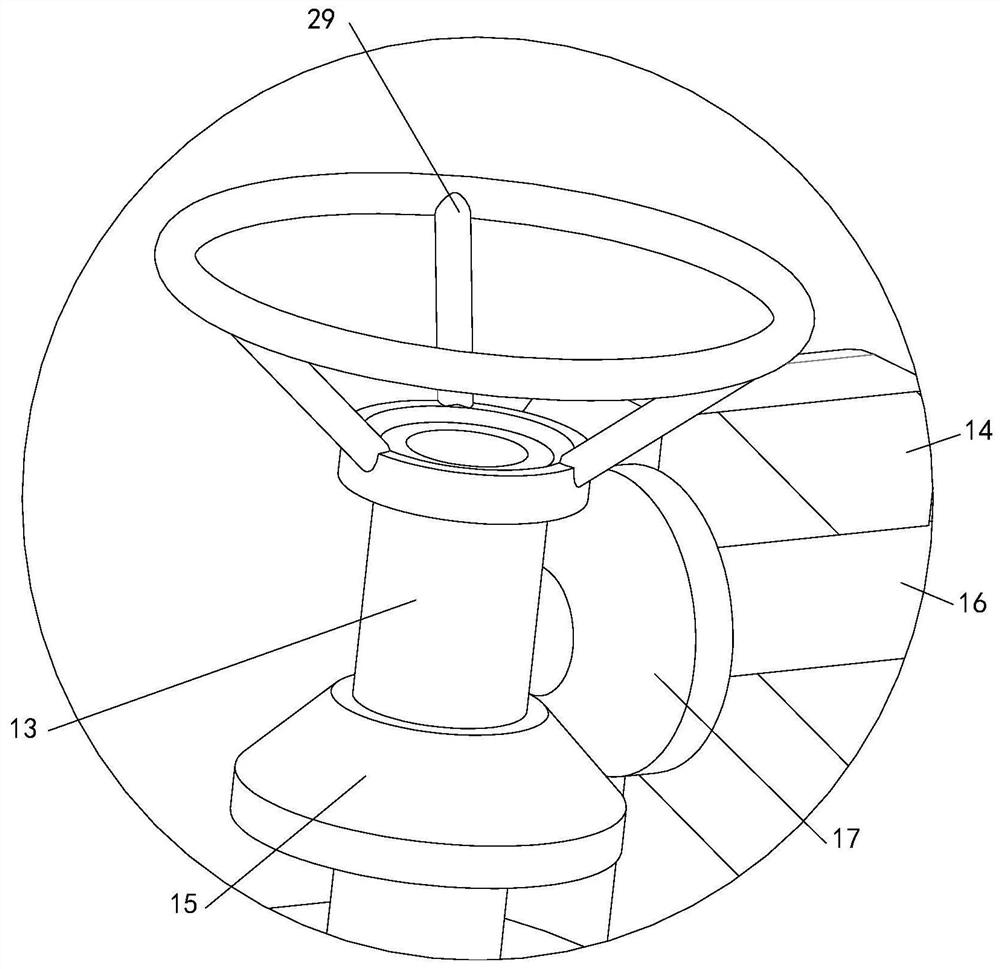

[0030] The regulator mechanism and the adjustment block mechanism are mounted in the left end frame 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com