Tea leaf drying device

A drying device and technology for tea leaves, applied in the directions of drying tea leaves, drying gas arrangement, drying solid materials, etc., can solve the problems of insufficient drying and drying, inconvenient operation, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

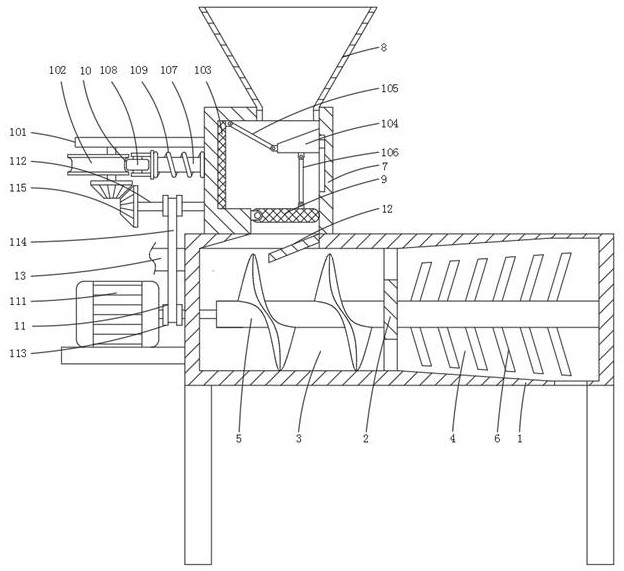

[0028] see figure 1 , a drying device for tea, comprising a drying box 1, the interior of the drying box 1 is divided into a feeding chamber 3 and a drying chamber 4 by a partition 2, the feeding chamber 3 is connected with a spiral blade 5 in rotation, and the drying chamber 4 There is a stirring rod 6 connected with the spiral blade 5 inside, the top of the drying chamber 4 is connected with a storage box 7, the top of the storage box 7 is pierced with a feed hopper 8, and the bottom of the storage box 7 is rotatably connected with a stopper. Plate 9, adjustment assembly 10 that provides the rotation of baffle plate 9 is provided on the outside of material storage box 7, and drive assembly 11 that provides screw blade 5 and adjustment assembly 10 is provided on the outside of drying box 1. Specifically, the drying process will be required The feeding hopper 8 is placed inside the storage box 7, and through the action of the baffle plate 9, the temporary placement of the tea ...

Embodiment 2

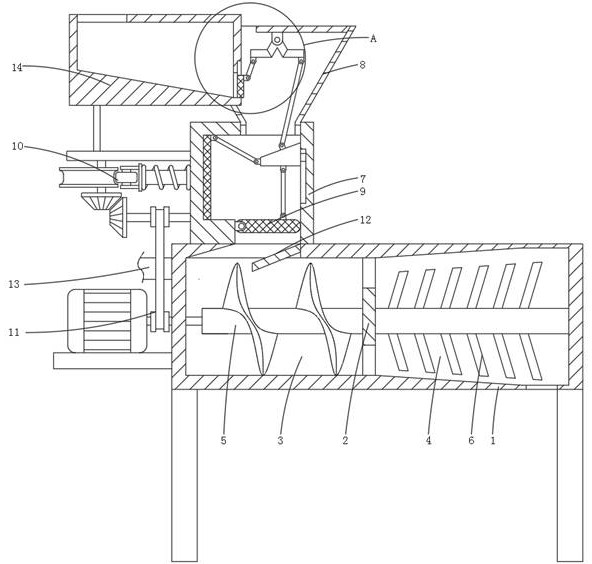

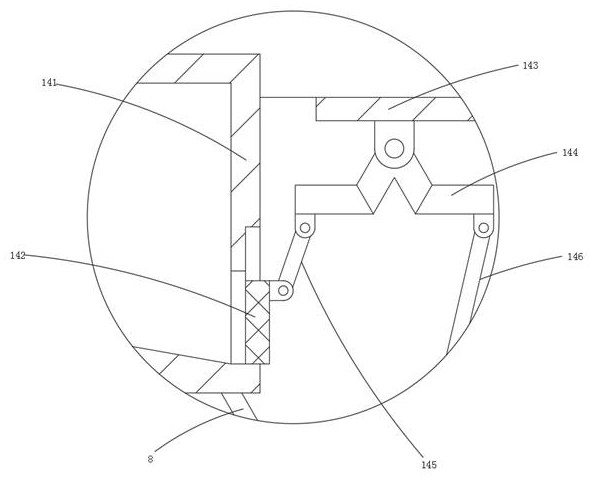

[0034] see figure 2 and image 3 , the top of the feed hopper 8 is also provided with a feed assembly 14, the feed assembly 14 includes a feed box 141 fixedly connected to the feed hopper 8, the inside of the feed box 141 is provided with a slope, and one side of the feed box 141 is slidingly connected with a sliding Block 142, the top of feed hopper 8 is fixedly connected with fixed plate 143, and the bottom of fixed plate 143 is connected with V-shaped bar 144 in rotation, is hinged with the 3rd connecting rod 145 between V-shaped bar 144 and sliding block 142, V-shaped bar A fourth connecting rod 146 is hinged between the other end of 144 and the pressing plate 104;

[0035] Based on the operation process of Embodiment 1, it can be seen that more tea leaves that need to be dried are stored in the feeding box 141, and the sliding block 142 is used to temporarily place it. Since the pressing plate 104 reciprocates up and down in the storage box 7, when pressing When the pl...

Embodiment 3

[0037] see Figure 4 , the inside of the feeding box 141 is rotatably connected with a rotating plate 15 , and a fifth connecting rod 16 is hinged between the rotating plate 15 and the roller 108 .

[0038] When the roller 108 moves towards the material storage box 7 , at this moment, the rotating plate 15 rotates towards the top of the material supply box 141 .

[0039] Based on the operation process of Embodiment 2, it can be seen that when the baffle plate 9 is in the open state, the roller 108 moves toward the material storage box 7. At this time, the rotating plate 15 is rotated by the action of the fifth connecting rod 16. At the same time, the charging box 141 The sliding block 142 at the place moves upwards, so that the tea leaves on the rotating plate 15 in the charging box 141 can better enter the feeding hopper 8, thereby further improving the automatic addition effect of the material in the charging box 141 to the storage box 7.

[0040] The drive motor 111 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com