Pre-drying system utilizing waste heat of textile drier

A dryer and pre-drying technology, applied in the direction of dryers, drying, heating devices, etc., can solve the problems of heat radiation pollution of high-temperature waste hot air flow, high energy consumption of textile dryers, and environmental impacts, etc., to achieve Improve the efficiency of drying treatment, reduce drying time, and reduce the effect of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

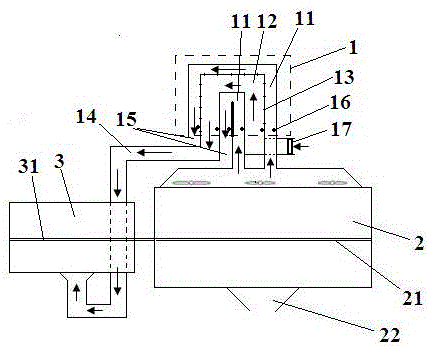

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 A pre-drying system using the waste heat of a textile dryer as shown includes a cloth pre-dryer 3 and a heat exchange device 1. The heat exchange device 1 is placed on the top of the cloth dryer 2 and includes a wet and hot exhaust gas channel 11 and The fresh dry air channel 12 is used to pump the hot and humid exhaust air and dry cold air discharged from the cloth dryer 2 respectively. A heat exchange device 13 is arranged between the hot and humid exhaust air channel 11 and the fresh dry air channel 12. The fresh dry air channel 12 The dry cold air circulating in the interior absorbs the heat of the hot and humid waste gas flowing through the hot and humid waste gas channel 11 by using the principle of heat exchange, and is discharged into the cloth pre-dryer 3 through the ventilation pipe 14 to pre-dry the cloth 31, and the cloth is pre-dried The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com