Technology for preparing fermented protein concentrated feed from dense slurry

A technology of concentrated feed and thick slurry, which is applied in animal feed, animal feed, food processing, etc., can solve the problems of high cost and nutritional damage of feed, achieve improved nutritional value, high feeding effect, maintain and regulate intestinal bacteria The effect of group balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

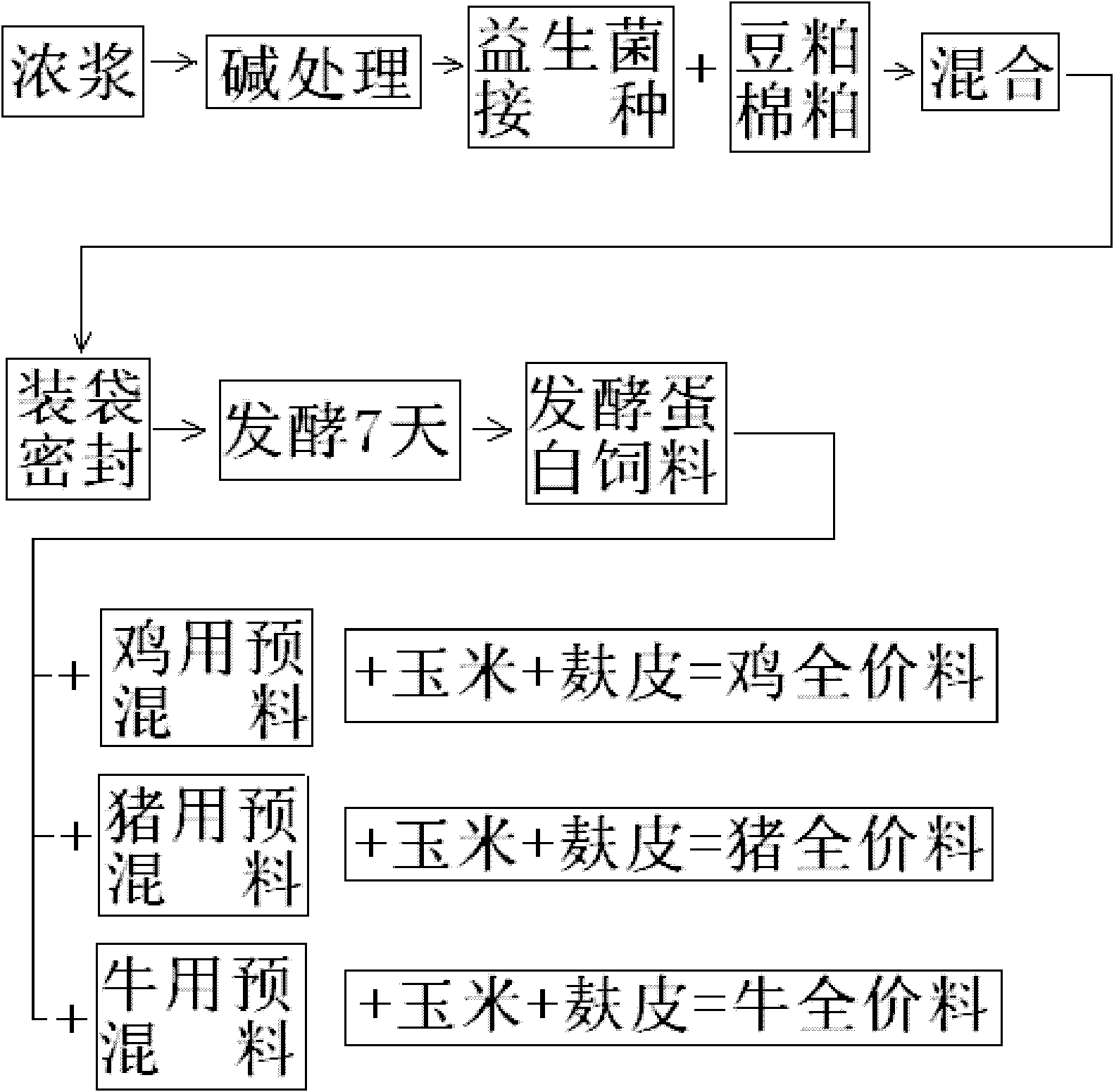

[0021] refer to figure 1 , a process for making fermented protein concentrated feed from thick pulp. The thick pulp purchased from the alcohol factory can be temporarily stored in the workshop. During production, put the thick slurry into a container equipped with stirring, heating and temperature control devices, and use a certain amount of alkali and calcium hydroxide (the ratio of the two is 2 to 1) to adjust the pH to neutral (about PH7.0 ), which not only provides a suitable environment for the cultivation of probiotics, but also provides abundant calcium, which increases the calcium content in the feed. Add a certain amount of probiotics (more than 80 aerobic and anaerobic beneficial bacteria in 5 families, 10 genera, etc.) strains, and set the temperature at 39 degree, stir. By measuring the change of pH in the culture, determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com