Detection method for metallic element in liquid crystal material

A technology of metal elements and liquid crystal materials, applied in the field of display liquid crystal material detection, can solve the problems such as the inability to guarantee the same amount of liquid crystal, the inability to meet the test requirements, the reduction of detection ability, etc. The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific examples. Unless otherwise specified, the reagents and equipment used in the present invention are conventional commercially available reagents and conventional equipment in the art.

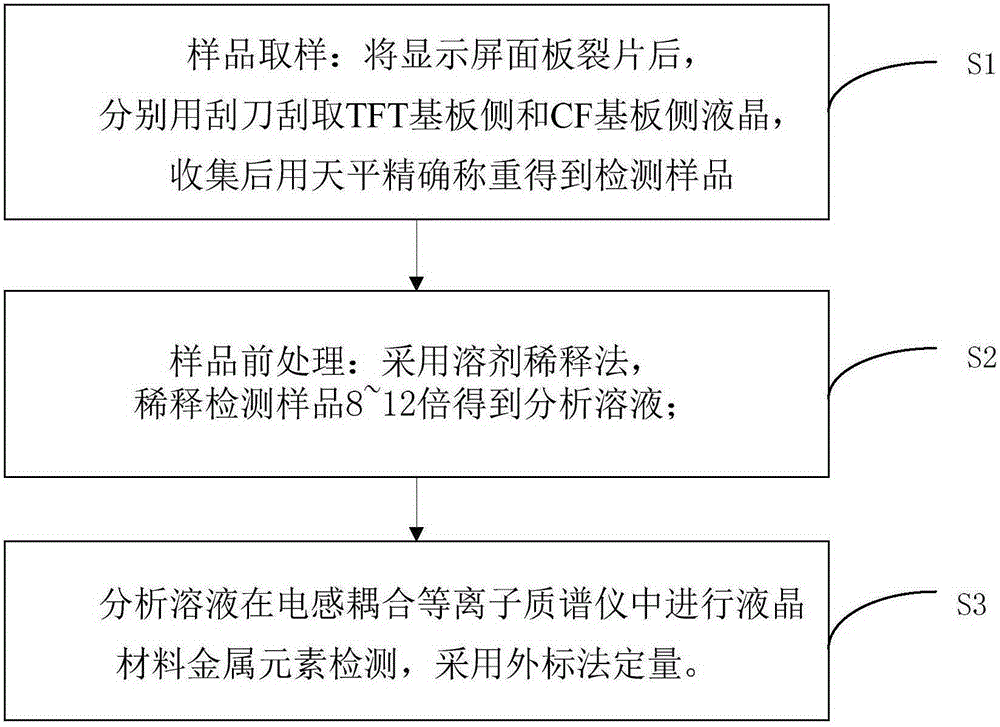

[0030] Embodiments of the present invention provide a method for detecting metal elements in liquid crystal materials, comprising the following steps:

[0031] Step S1, sample sampling: After splitting the thin film transistor liquid crystal display panel, use a plastic scraper to scrape the liquid crystals on the TFT substrate side and the CF substrate side respectively, collect them into sample bottles, and accurately weigh them with a balance to obtain test samples;

[0032] Step S2, sample pretreatment: using solvent dilution method, using iso-propylalcohol (IPA) as liquid crystal dilution solvent, diluting the detection sample obtained in step S1 by 8 to 12 times (preferably 10 times) to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com