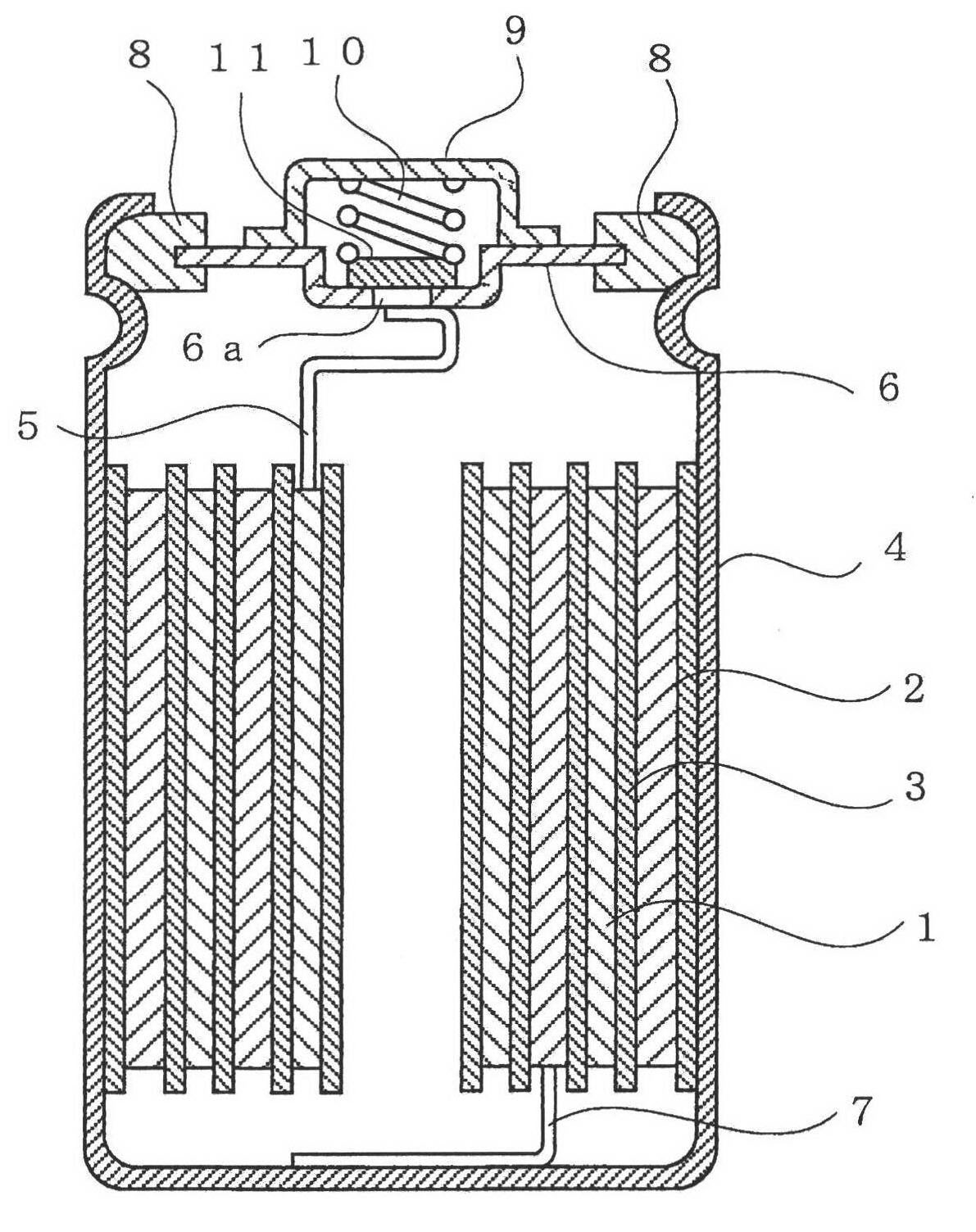

Hydrogen-absorbing alloy, fabrication method thereof and alkaline storage battery

一种贮氢合金、制造方法的技术,应用在碱性蓄电池、碱性蓄电池电极、镍蓄电池等方向,能够解决贮氢合金开裂、碱性蓄电池循环寿命降低等问题,达到抑制体积变化之差、抑制龟裂、高容量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

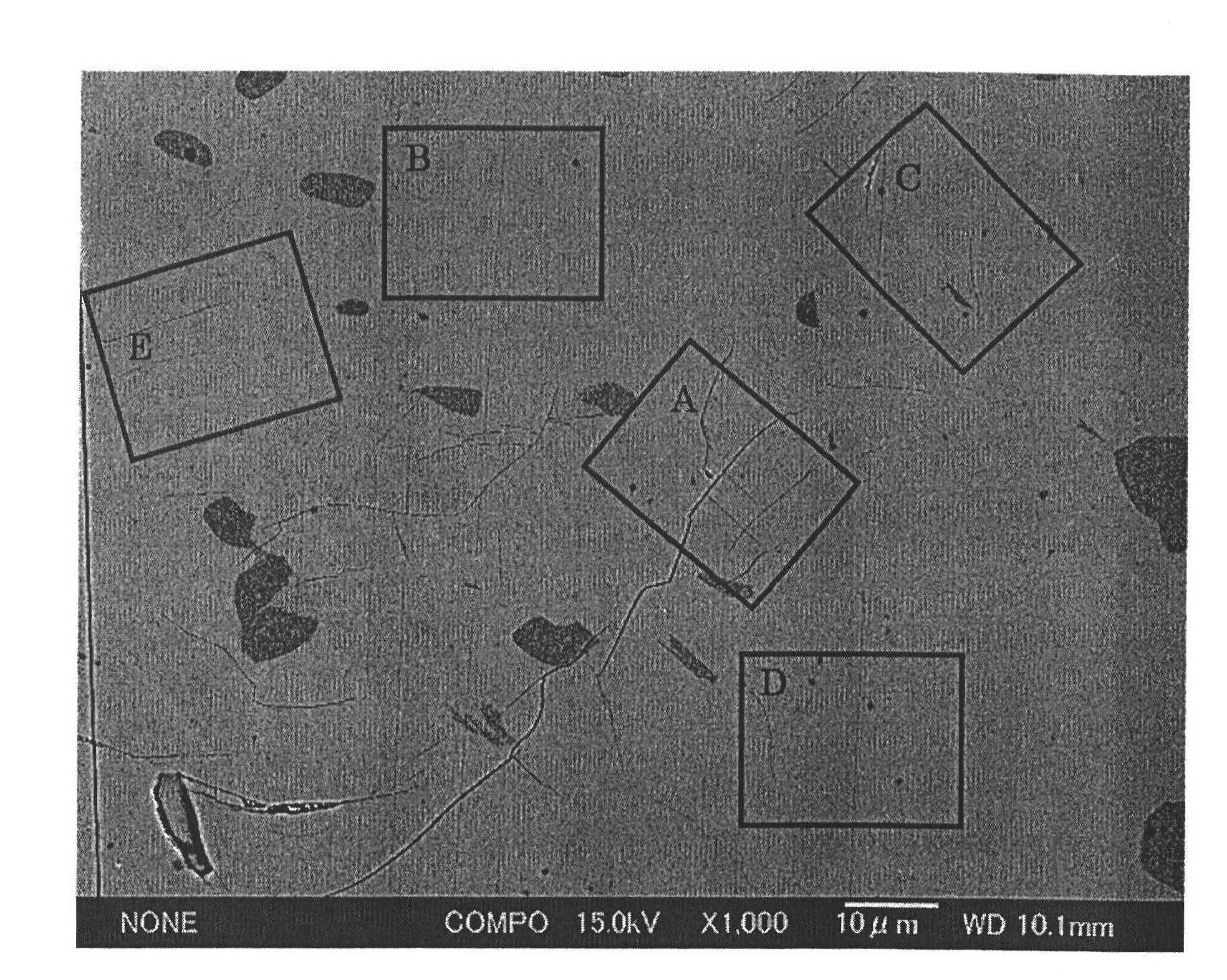

[0059] In the alkaline storage battery of Example 1, when producing the hydrogen storage alloy used in the negative electrode active material of the negative electrode, the rare earth elements La, Ce, and Nd were mixed with Mg, Ni, and Al according to the specified alloy composition, and the hydrogen storage alloy was mixed in an argon atmosphere. After melting in a high-frequency induction melting furnace, it was poured into a mold and cooled to room temperature to obtain an ingot of a hydrogen storage alloy. Here, the composition of the hydrogen storage alloy thus obtained was analyzed by high-frequency plasma emission spectrometry (ICP), and as a result, the composition was (La 0.3 Ce 0.4 Nd 0.3 ) 0.85 Mg 0.15 Ni 3.3 Al 0.2 . In addition, the melting point of the hydrogen storage alloy was measured with a differential scanning calorimeter (DSC), and the melting point was 1015°C.

[0060] Then, heat-treat the ingot of the hydrogen storage alloy in a furnace in an argo...

Embodiment 2

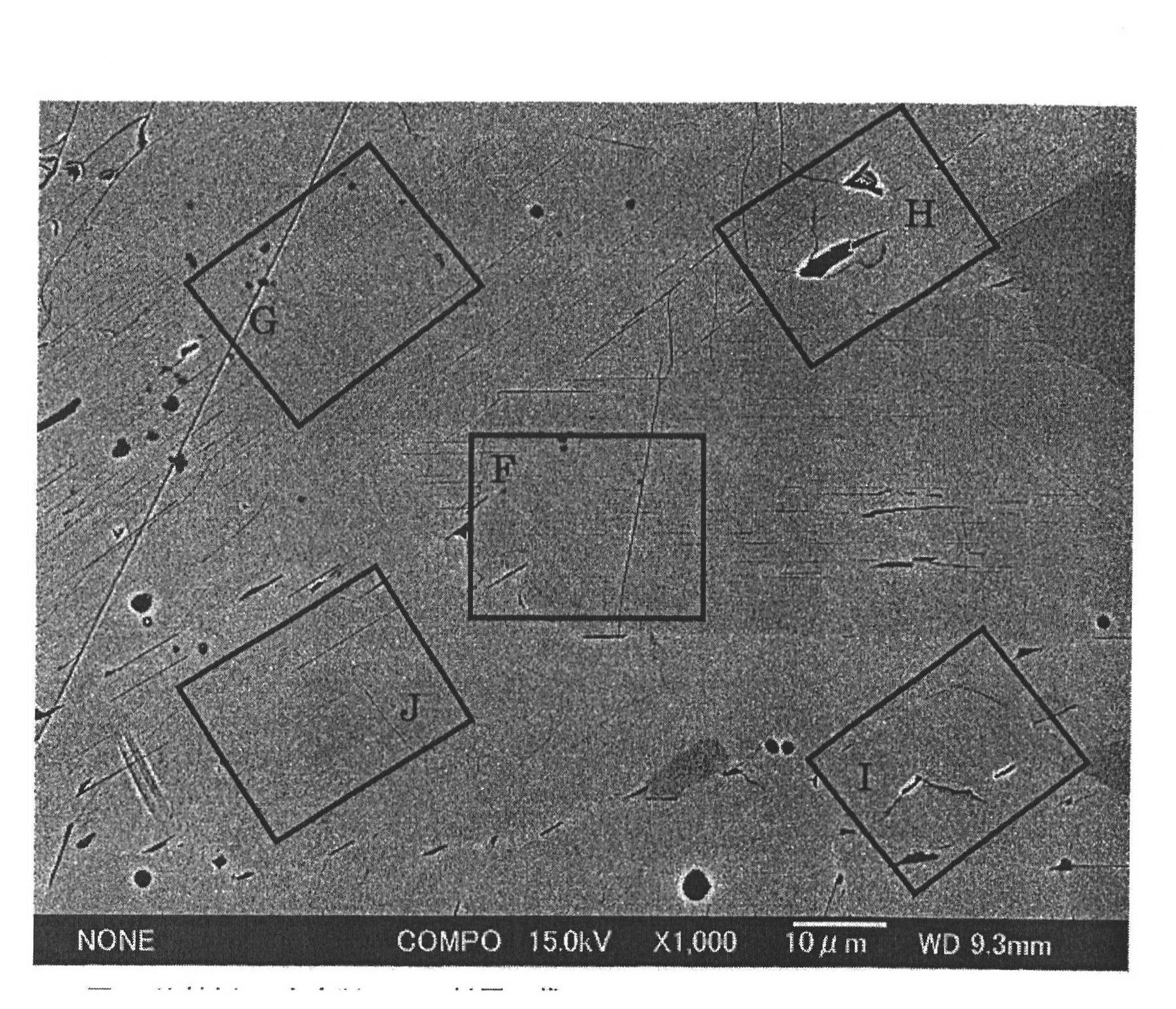

[0085] In the alkaline storage battery of Example 2, when manufacturing the hydrogen storage alloy used for the negative electrode active material, the rare earth elements La and Sm are mixed with Mg, Ni, and Al according to the specified alloy composition, and they are melted in a high-frequency induction melting furnace. After melting in an argon atmosphere, it was poured into a mold and cooled to room temperature to obtain an ingot of a hydrogen storage alloy. Here, the composition of the hydrogen storage alloy thus obtained was analyzed by high-frequency plasma emission spectrometry (ICP), and as a result, the composition was La 0.65 SM 0.15 Mg 0.20 Ni 3.40 Al 0.20 . In addition, the melting point of the hydrogen storage alloy was measured with a differential scanning calorimeter (DSC), and the melting point was 980°C.

[0086] Next, the ingot of the hydrogen storage alloy was heat-treated in a furnace in an argon atmosphere at a temperature of 50°C lower than the mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com