Pneumatic circulating grain drier

A kind of grain dryer and circulation technology, which is applied in the direction of drying and preserving seeds, food science, etc., can solve the problems of limited application range and processing range, increased drying cost, corn form gelatinization, etc., and achieve saving drying Effects of cost and labor costs, reduction in drying time, and reduction in drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

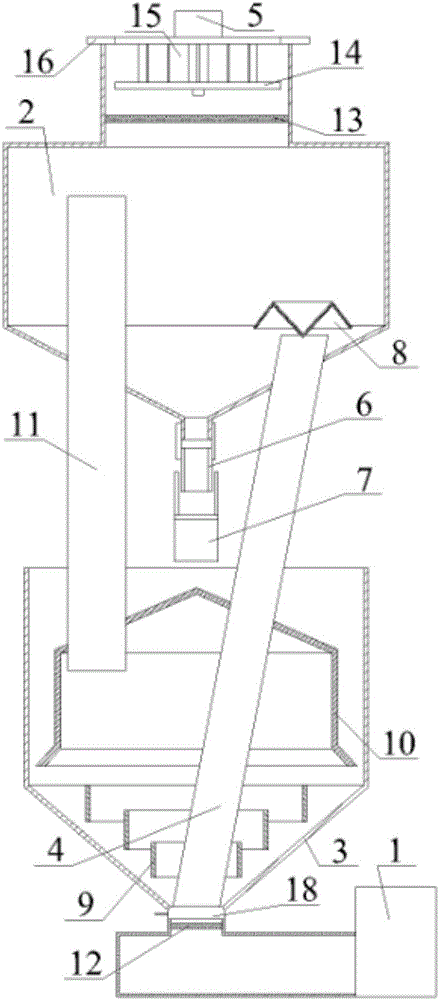

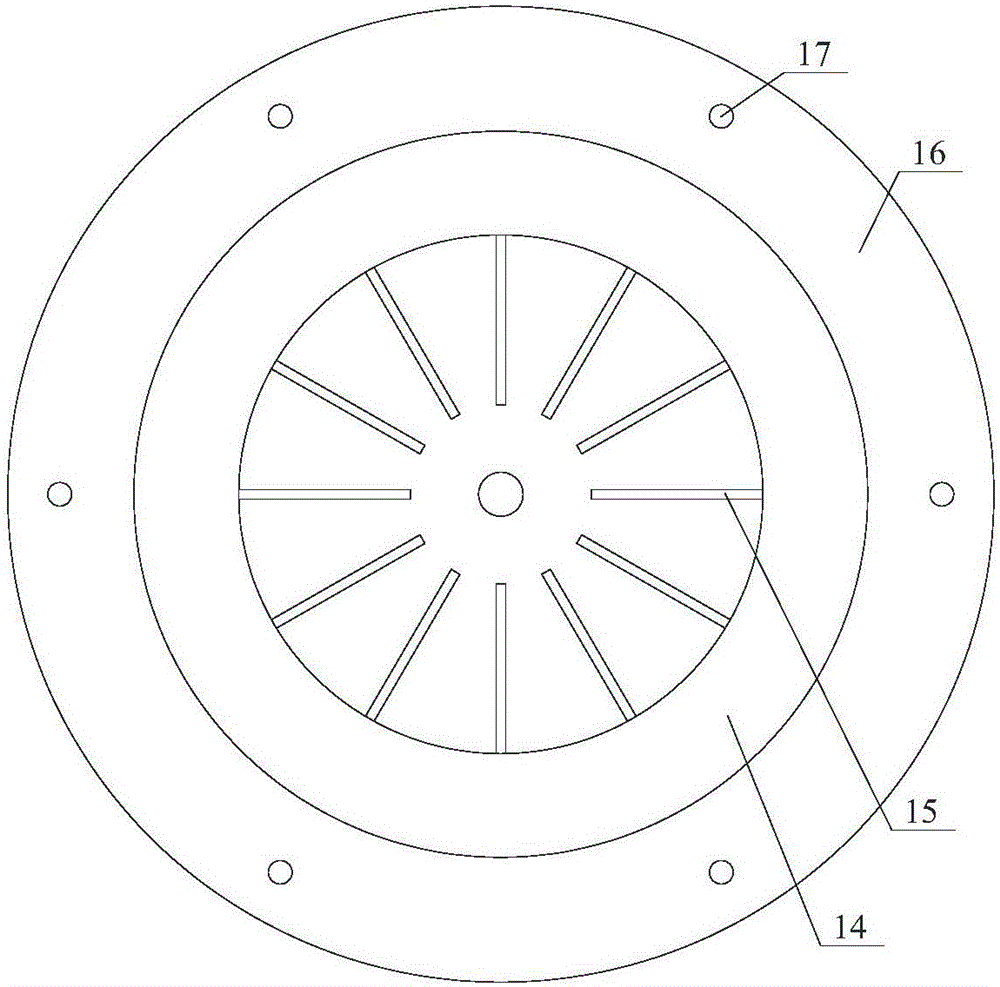

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

[0038] Specific examples, such as figure 1 and figure 2 As shown, the air suction circulation type grain dryer includes a heat source 1 and an oven. The heat source 1 is a hot blast stove. The hot air outlet of the heat source 1 is connected to the hot air inlet of the oven. The oven includes an upper separation chamber 2, a drying upper beam cylinder 4 and a lower end The lower grain storage room 3 is a funnel-shaped structure. The lower grain storage room 3 is provided with a material inlet, and the upper separation room 2 is provided with a material outlet and an air outlet. During the drying and dehydration process, some harmful substances in the grain are discharged, so that the quality of the grain remains original. A cylindrical louver 9 is added inside the funnel-shaped structure, the louver 9 is fixedly connected with the lower grain storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com