Recycled aggregate concrete preparation method

A recycled aggregate and concrete technology, applied in the field of building materials and building materials, can solve the problems of wasting natural resources, consuming large coal resources, and increasing additional costs, saving labor, time, labor, and additional costs, protecting natural resources, and eliminating additional costs. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

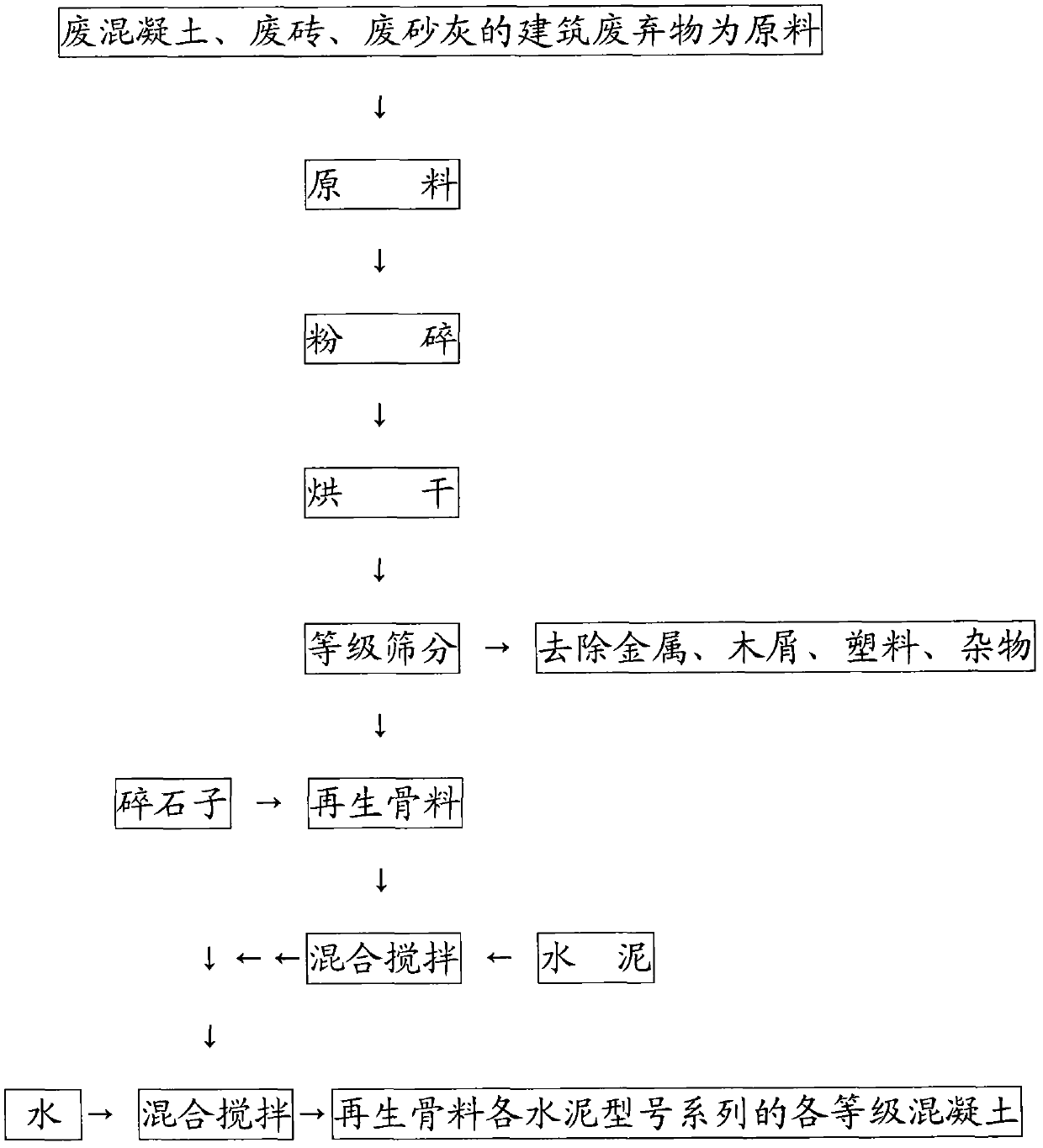

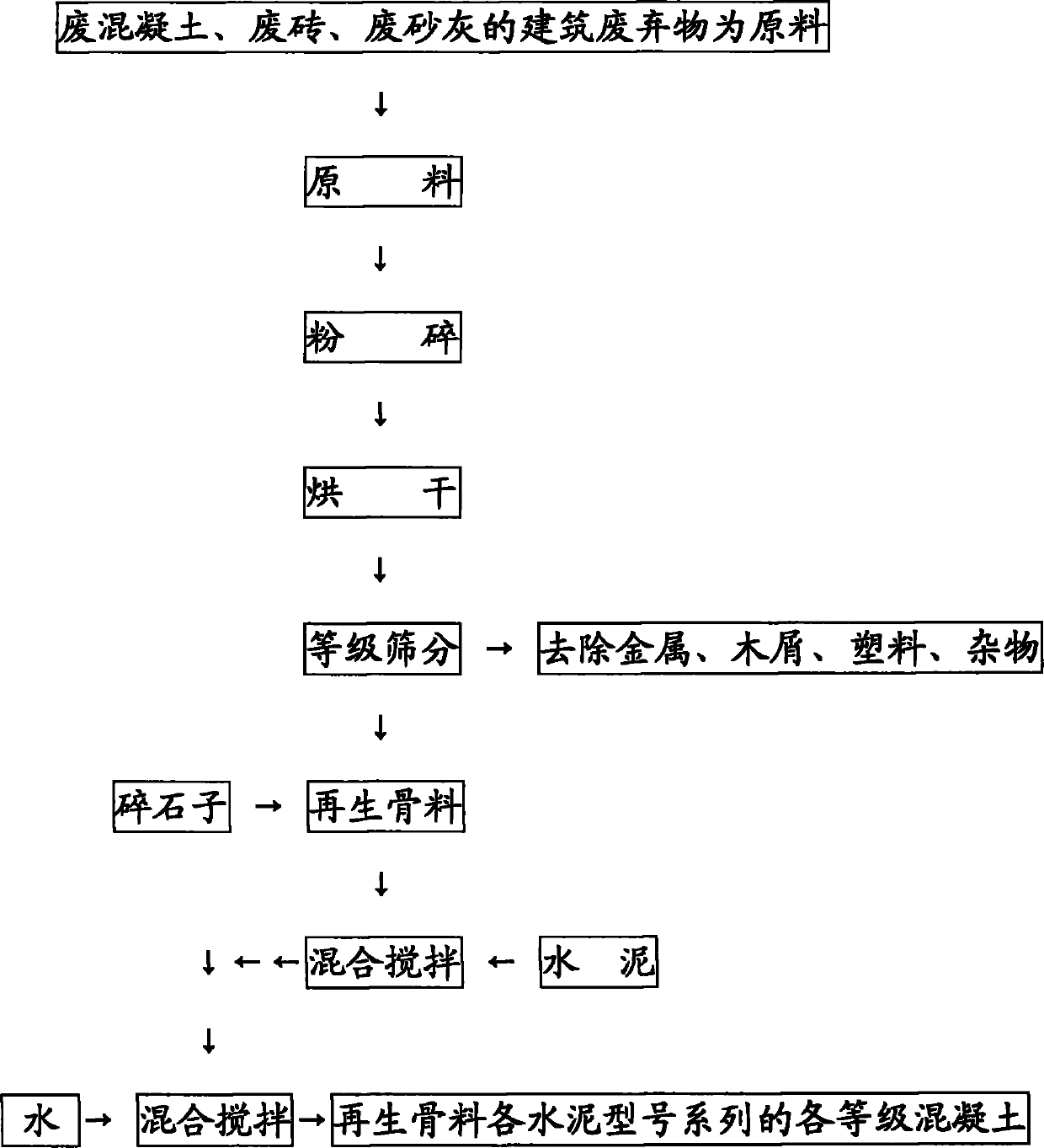

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0054] A kind of preparation method of recycled aggregate concrete:

[0055] (1) Preparation of recycled aggregate: Use waste concrete, waste bricks, and waste sand and ash construction waste less than 690mm in size as raw materials, determine the quantity according to needs, and carry out grade screening after crushing and drying with a moisture content of less than or equal to 0.5%. In the grade screening process, magnets are used to remove metals, and wood chips, plastics and sundries are removed in the manner of specific gravity, so that the particles are prepared into 0.3-0.6mm, 0.6-1.18mm, 1.18-2.36mm, 2.36-4.75mm For recycled aggregates, the recycled aggregates are stored separately according to different particle sizes for later use;

[0056] (2) Proportion of cement type P.C 32.5 series concrete:

[0057] (2). ①. The...

specific Embodiment approach 2

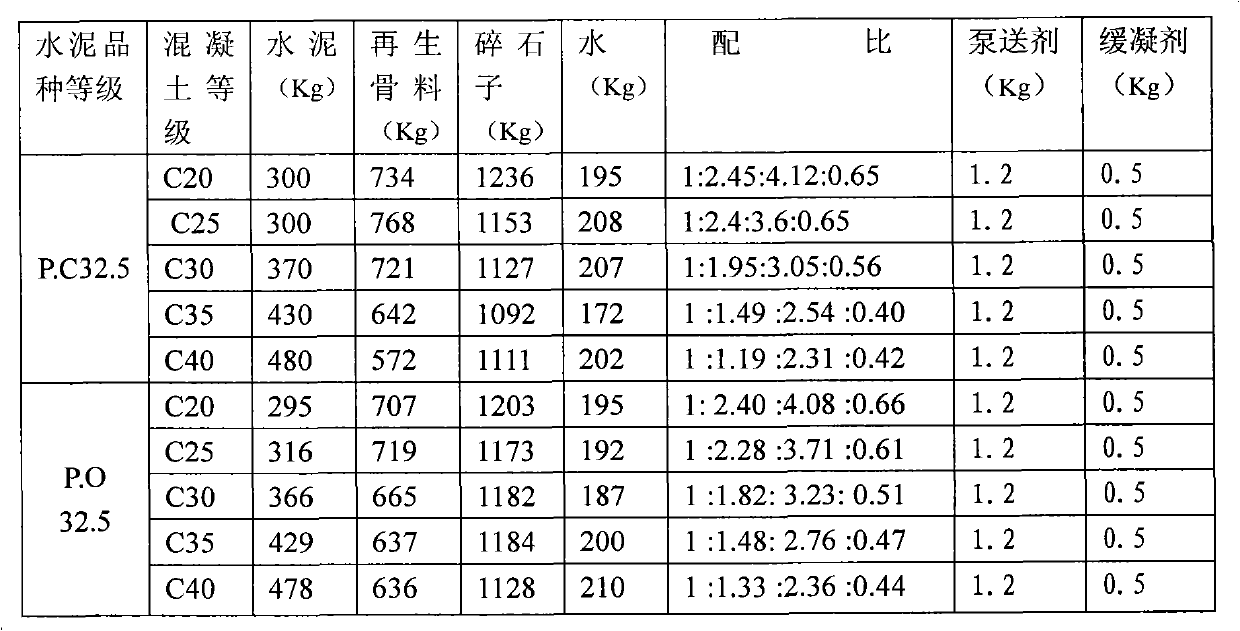

[0091] Carry out according to the specific implementation mode 1, only the specific proportioning ratio of each cement model series and each grade concrete of the recycled aggregate is as follows:

[0092]

[0093]

[0094] Also received the expected good results.

specific Embodiment approach 3

[0095] Carry out according to specific embodiment one, two, on the implementation basis of specific embodiment two, take the quantity two of specific embodiment as the basis, and reduce 1,2,5,8,10,15,20 respectively on this basis , 25, 30, 35, 40, 45, and 50 times were implemented; on this basis, they were expanded by 1, 2, 5, 8, 10, 15, 20, 25, 30, 35, 40, 45, and 50 times Implemented; thereby obtained multiple repeated tests of various scales of principle test, small-scale test, laboratory test, expansion test, medium-scale test, large-scale test, and production test, all of which have obtained expected good results, making this project The invention has a solid foundation from principle to implementation, creating good conditions for practical application and laying a solid foundation for widespread application.

[0096] After the production of the present invention, a trial assessment was carried out. During the trial assessment, experts in the industry agreed that: the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com