Insulator cleaning robot system

A technology for cleaning robots and insulators, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of insulator sheets not being cleaned, limited cleaning range, and incomplete cleaning, etc., to increase work The effect of stability, fast moving speed and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

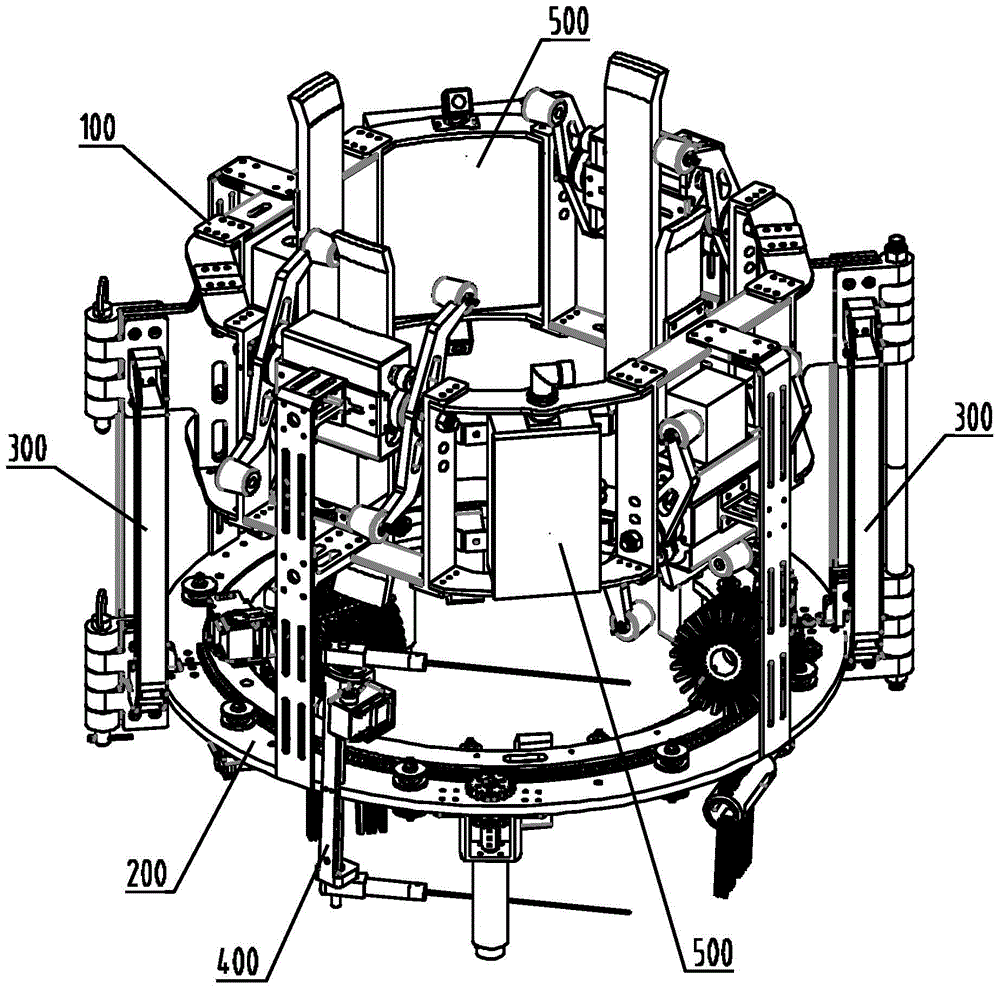

[0048] The present invention crawls on the insulator string and is used for cleaning the insulator string, such as figure 1 As shown, the robot as a whole has a circular structure, including a crawling mechanism 100 , a cleaning mechanism 200 , a locking mechanism 300 , a detection mechanism 400 and a battery control system 500 . The crawling mechanism 100 and the cleaning mechanism 200 are connected through the locking mechanism 300 , the detection mechanism 400 is arranged on one side of the locking mechanism 300 , and the control box 500 is arranged on the crawling mechanism 100 .

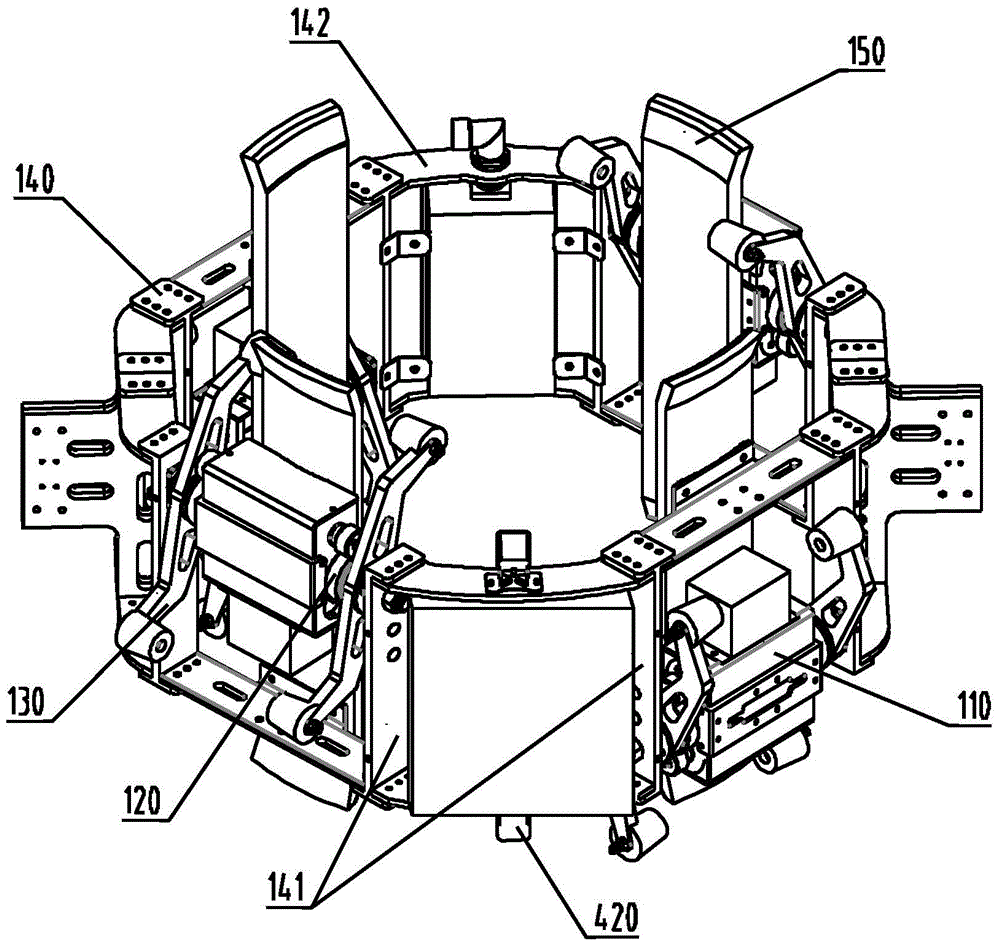

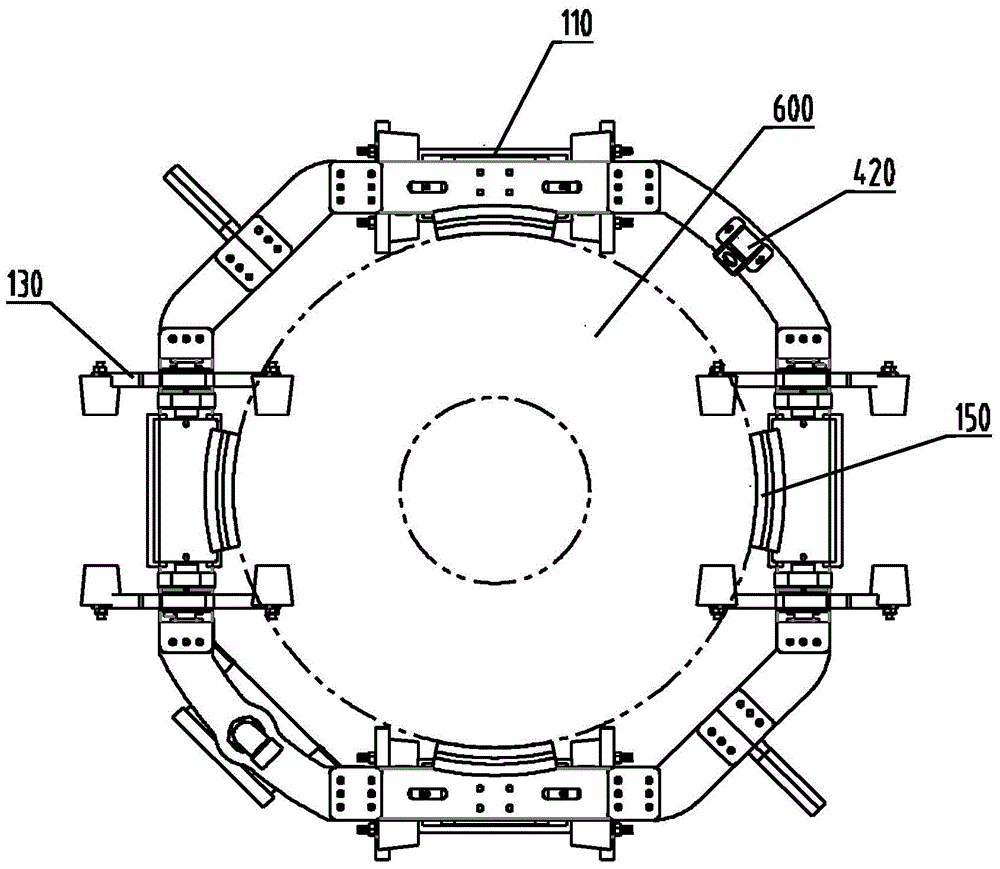

[0049] Such as figure 2 , image 3 , Figure 4 As shown, the robot crawling mechanism 100 is a closed circular structure, surrounded by insulator strings, and can be opened and closed. It is mainly composed of a driving mechanism 110, a connecting mechanism 140 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com