Ring spinning machine having a false twist device

The invention relates to a ring spinning machine and a technology for ring spinning, which can be applied to continuous winding spinning machines, spinning machines, open-end spinning machines, etc., and can solve the problem of high cost, reduce energy consumption, and reduce end breaks. risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

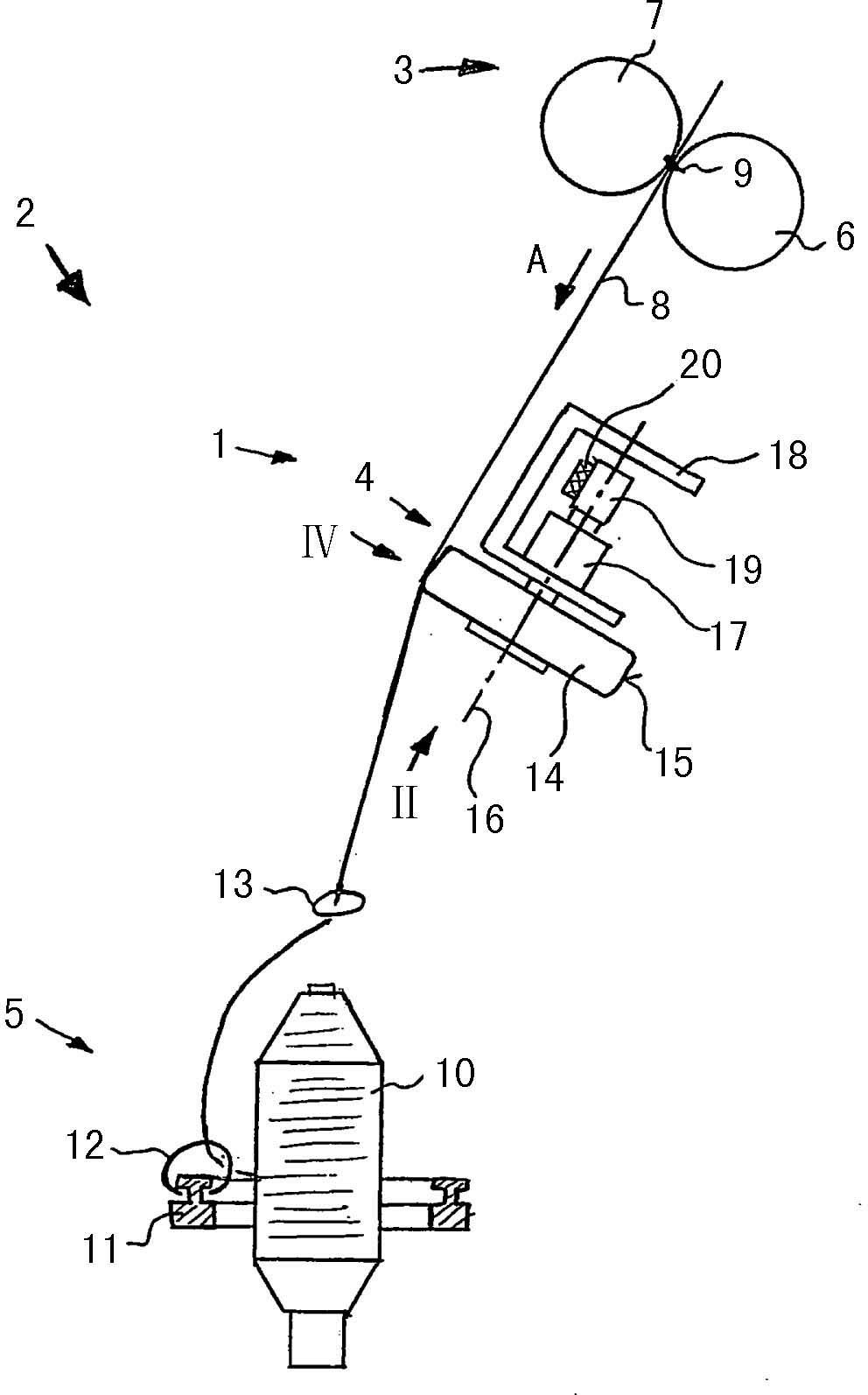

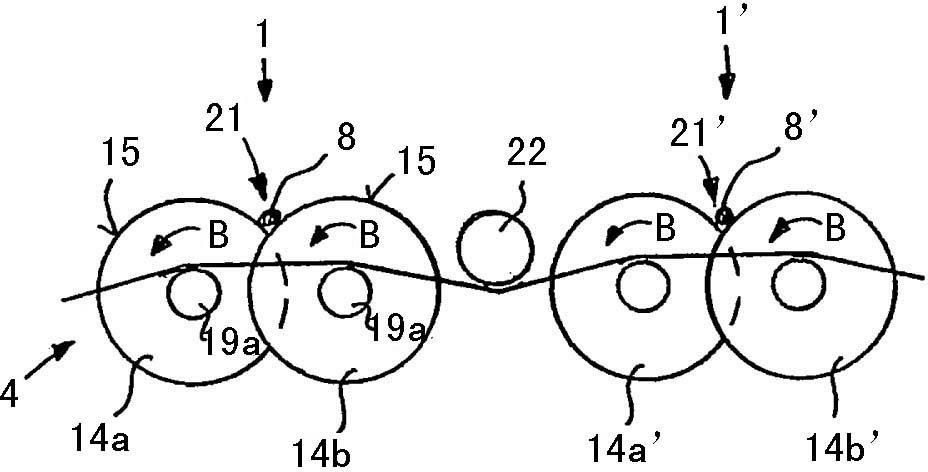

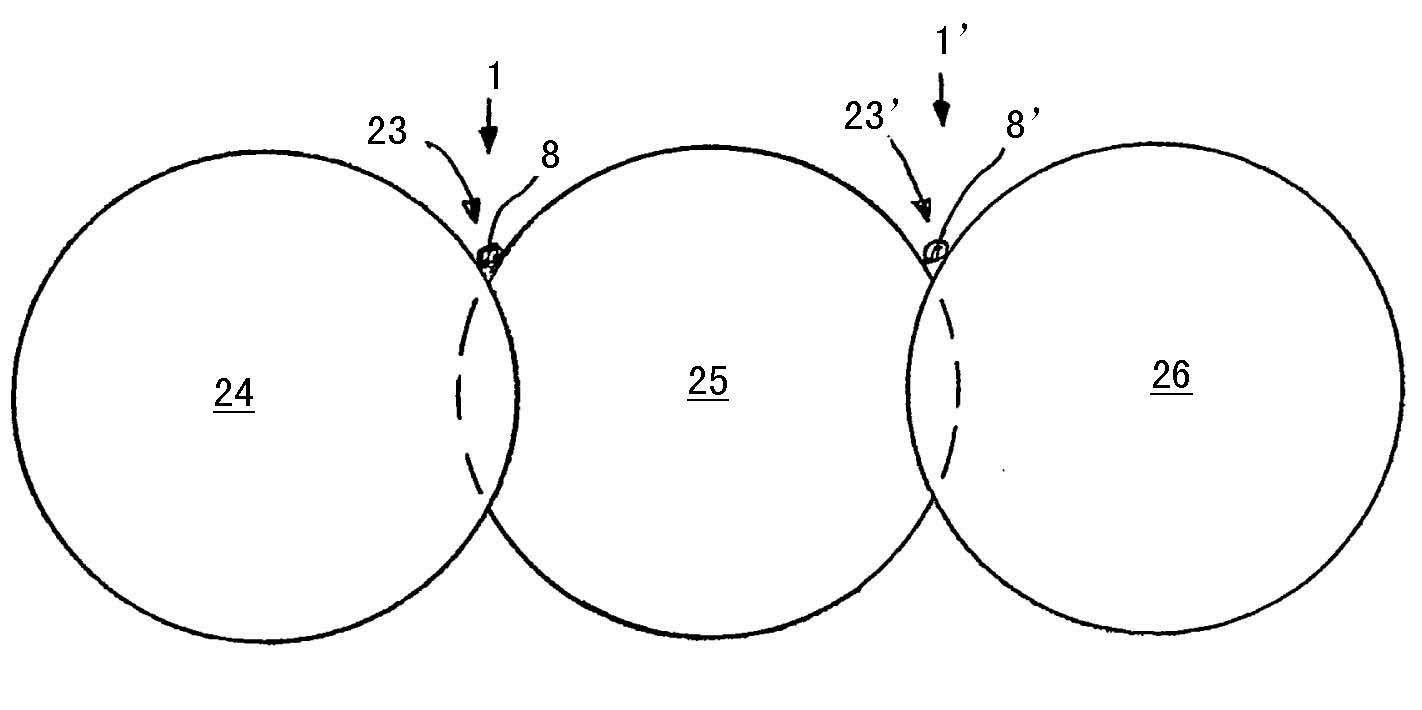

[0019] in figure 1 In this, a very schematic view of the spinning station 1 of the ring spinning device 2 is shown. The spinning station includes a drafting unit 3, a false twisting device 4 and a spindle 5 for a ring spinning machine. Only the front roller pair 6 including the lower roller 6 and the upper roller 7 pressed on the lower roller 6 is displayed in the drafting unit 3. The drafting unit 3 may include more roller pairs (not shown) in a known manner, which are used to stretch the fiber bundle 8 from staple fibers to the required fineness. The fiber bundle 8 is fully stretched at the clamping line 9 of the front roller pair 6 and 7 and is conveyed along the conveying direction A to the spindle 5 for the ring spinning machine.

[0020] The spindle 5 for a ring spinning machine includes a bobbin 10 that winds the twisted fiber bundle 8 into a yarn. The spool 10 is rotatable. The spinning ring 11 and the traveler 12 are provided on a spindle 5 for a ring spinning machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com