Gravel grouting pile with extruding and expanding supporting discs and construction method thereof

A technology of squeezing and expanding the support plate and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of occupying a large area of land, waste, environmental pollution, etc., to improve pile side resistance, reduce settlement, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

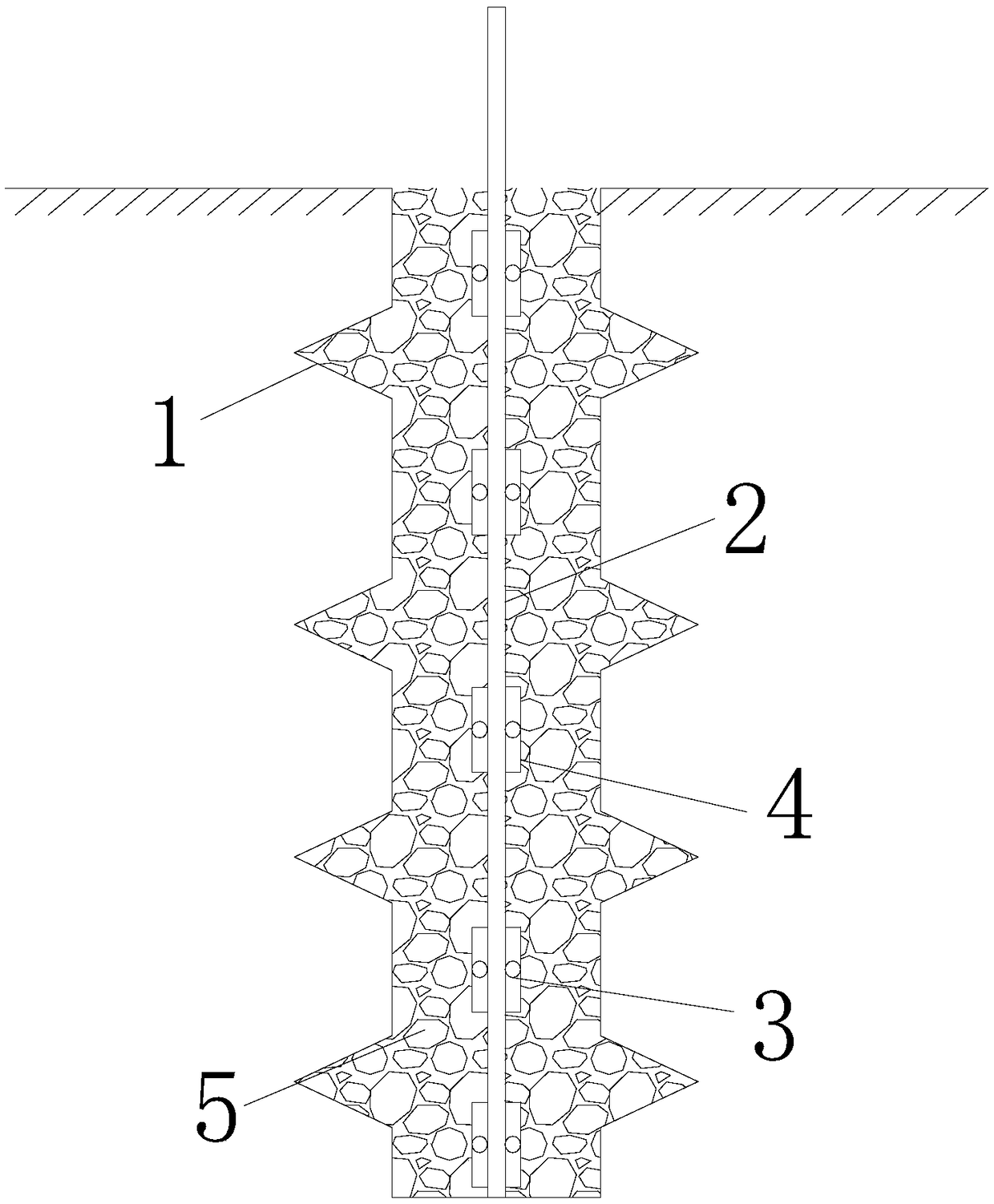

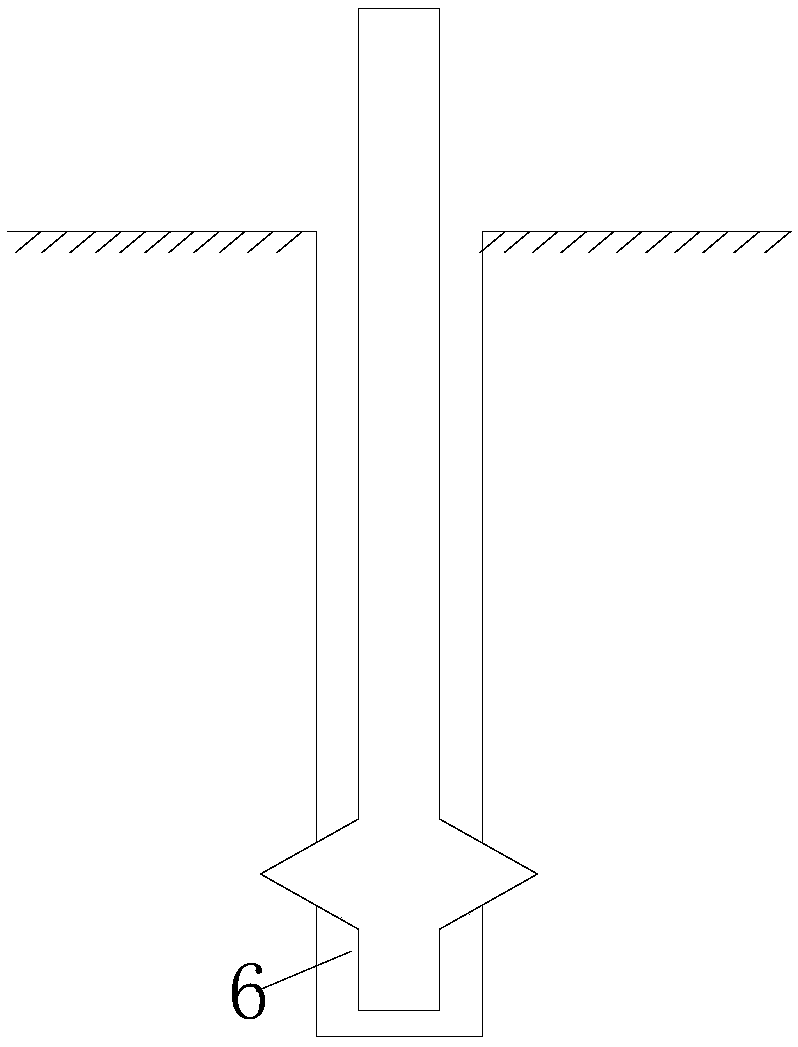

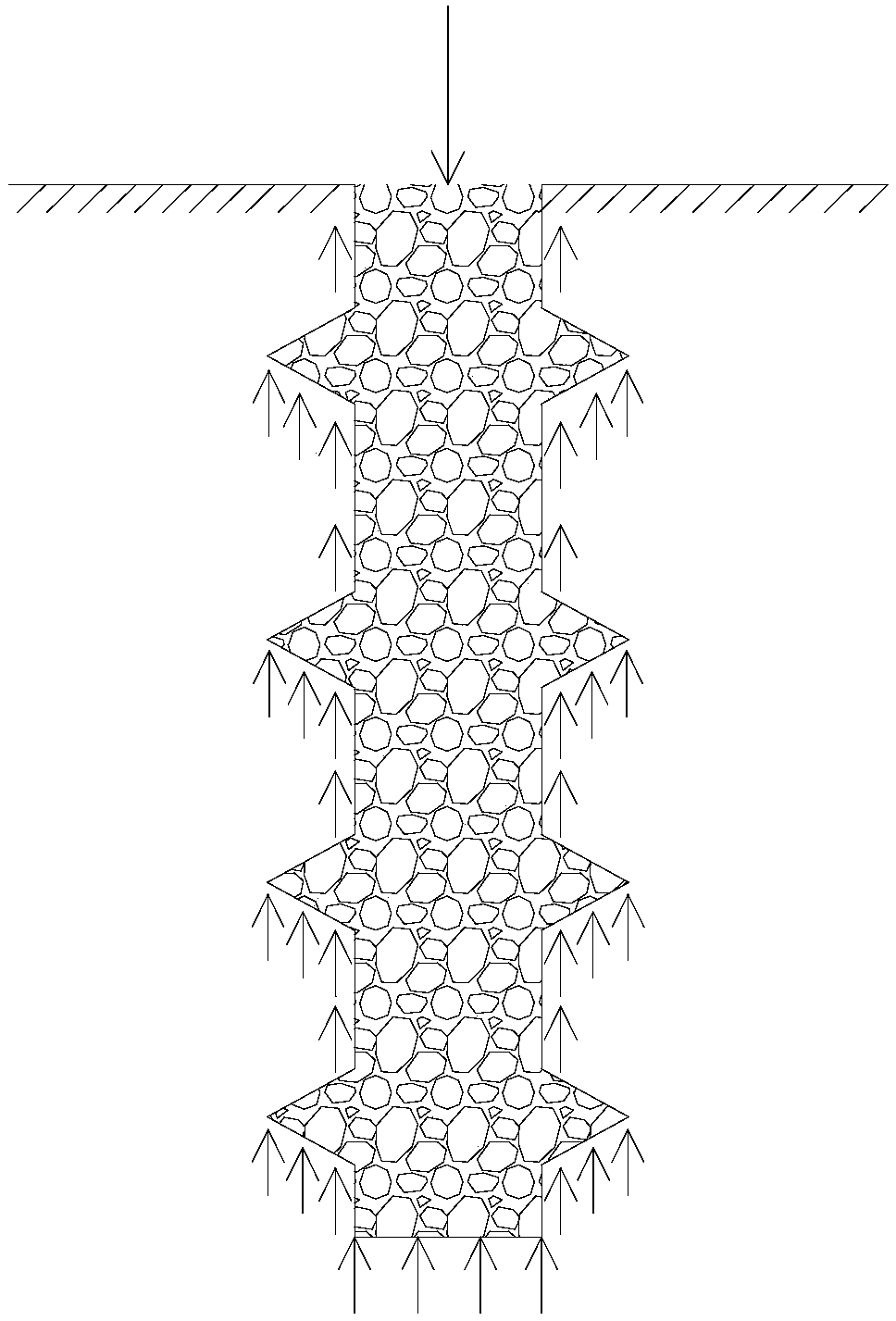

[0033] Such as figure 1 and combine Figure 2 to Figure 4 As shown, a specific embodiment of the crushed stone grouting pile with a graded enlarged head of the present invention includes a support plate body, a grouting pipe 2, a prefabricated hole 3, a geotextile 4, crushed stones 5, and a crushed stone slurry solidified pile body 8 , the grouting pipe 2 is arranged at the center of the gravel slurry solid pile body 8, the prefabricated holes 3 are circularly distributed on the pipe wall of the grouting pipe 2, and the geotextile 4 is wrapped around the outside of the prefabricated holes 3 , the crushed stone 5 is wrapped on the upper part of the grouting pipe 2, and the support disc body is located on the outer wall of the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com