Tipping paper rewinding machine on basis of servo system

A technology of servo system and rewinding machine, which is applied in winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of low surface tension of base paper rolls, large surface tension of base paper rolls, and paper breakage, etc., to achieve The effect of maintaining constant paper surface tension, improving quality, and flattening the disk surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

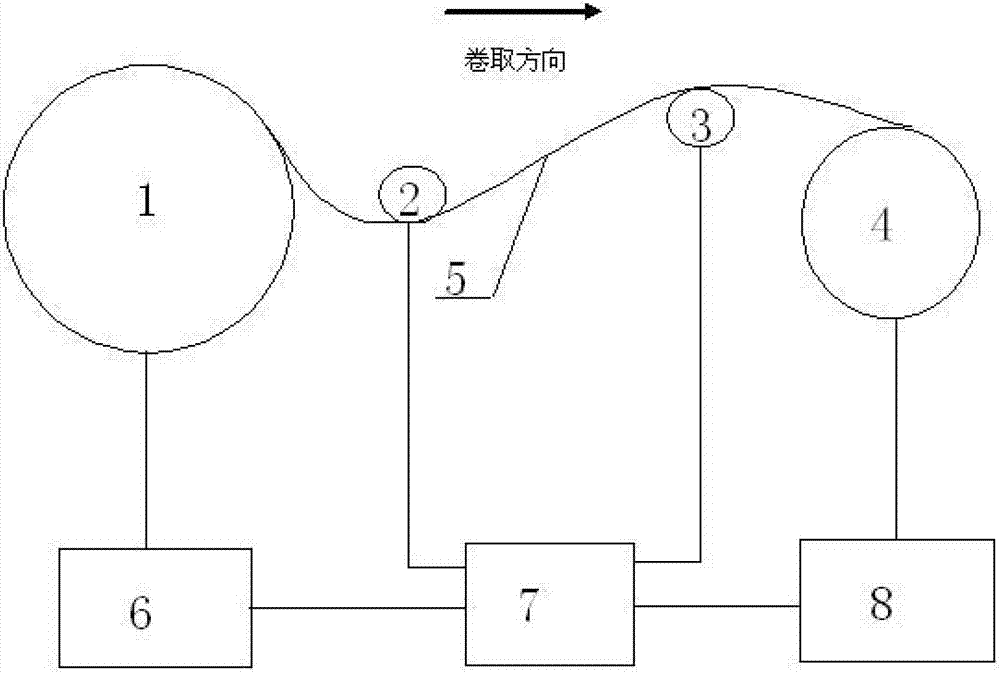

[0020] This embodiment describes a tipping paper rewinder based on a servo system, and its system structure is as follows figure 1 As shown, the tipping paper rewinder includes a central processing unit 7, an unwinding system, a winding system, and a tension roller 2 and a speed measuring roller 3 arranged between the unwinding system and the winding system. The unwinding system It includes an unwinding motor 6 and an unwinding reel 1 driven by an unwinding motor 6. The rewinding system includes a rewinding motor 8 and a reel 4 driven by the rewinding motor 8. The central processing unit 7 is connected to the unwinding The motor 6, the winding motor 8, the tension roller 2, and the speed measuring roller 3. The central processing unit 7 is used to adjust the unwinding motor 6 and the winding motor 8 according to the tension of the tension roller 2 and the speed measured by the speed measuring roller 3. Rotating speed. The unwinding motor 6 and the rewinding motor 8 both adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com