Manufacturing method of warp self-feeding and seaming polyester three-layer forming fabric for papermaking

A papermaking forming wire and manufacturing method technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of weak bonding force, low fiber support index, uneven mesh, etc., to maintain tightness and uniformity , The net structure is tight and uniform, and the interlayer bonding force is firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

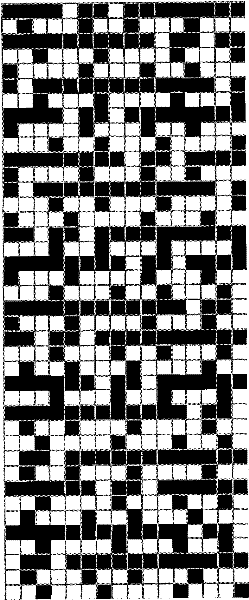

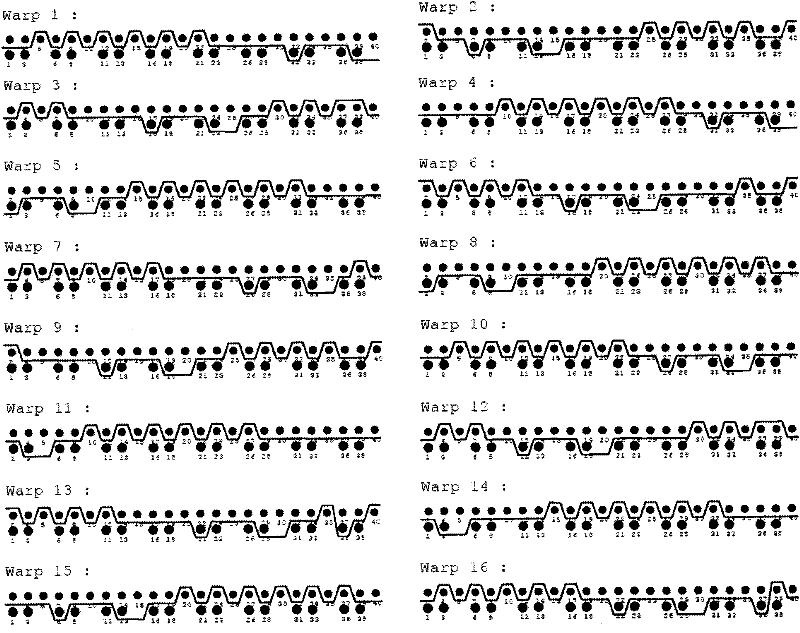

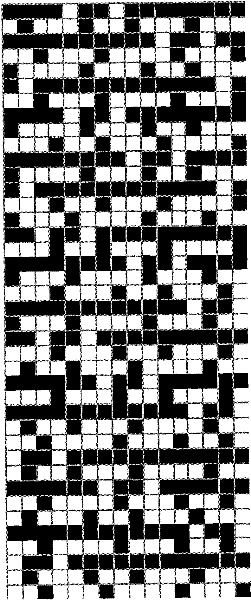

[0012] Take coarse mesh as an example, in figure 1 , 2 Among them, the manufacturing method of the warp self-sufficient sewing polyester three-layer paper-making forming net of the present invention adopts 16 heald frames to interweave polyester or nylon monofilaments into three different weaving structures of paper layer, intermediate connecting layer and machine layer to form An overall composite interlaced fabric, the smallest organizational unit of which is composed of 16 polyester monofilaments as warp threads and 40 polyester or nylon monofilaments as weft threads; the ratio of the number of warp threads between the paper-forming layer and the machine layer is 1:1 , the ratio of the number of weft threads between the paper-forming layer and the machine layer is 3:2; in the paper-forming layer, a 1 / 1 plain weaving method is adopted, and the diameter of the warp is 0.22mm; the diameter of the weft is 0.20-0.22mm; The material is made of all polyester monofilament, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com