Shield machine rotary joint

A technology of rotary joints and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve the problems of small cutter head diameter and inability to install rotary joints, etc., and achieves the effect of good integrity and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

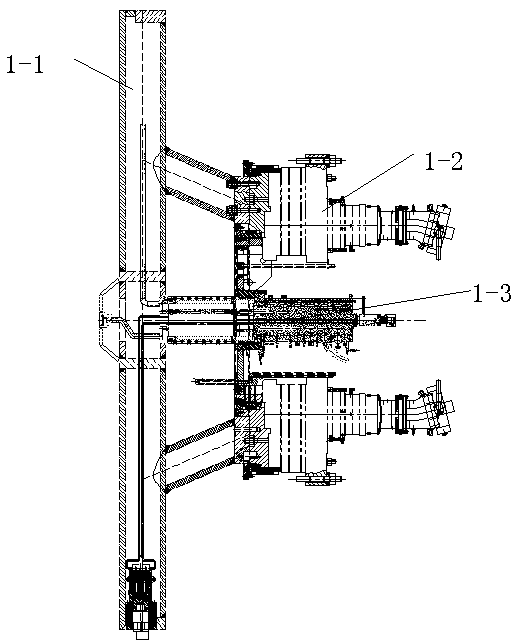

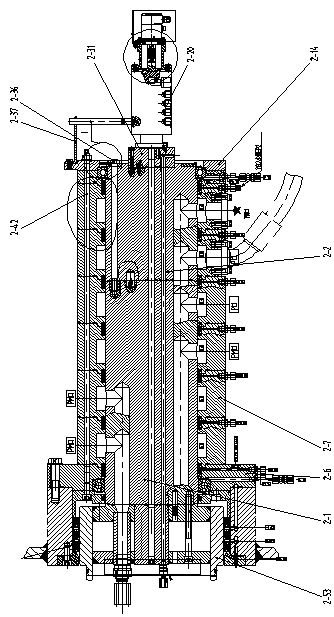

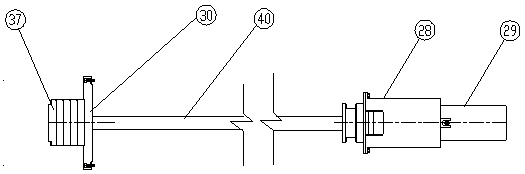

[0024] like Figure 2-7 As shown, the rotary joint of the shield machine of the present invention includes a small rotary joint 29, a rotor, a stator, a sealing assembly and a rotary support, the stator is sleeved outside the input end of the rotor, and the sealing assembly and the rotary support are arranged between the stator and the rotor. The small swivel joint 29 is connected with the input end of the rotor. The medium is injected into the rotor from the small rotary joint 29, and the output end of the rotor is connected with the cutter head, and the medium is injected into the front of the cutter head. When the medium is conveyed, the stator is fixed, and the rotor rotates synchronously with the cutter head.

[0025] The stator includes a shell 28, a connecting seat 9, a retaining ring 14 and a bolt one 15, the connecting seat 9 is fixed on the front part of the shell 28 by a bolt one 15, and the retaining ring 14 is fixed on the connecting seat 9 front part by a bolt on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com