Mesh bag free corrugated filter board

A filter plate and corrugated technology, which is applied in the field of corrugated filter plates without mesh bags for disc filters, can solve problems affecting production and cost, and achieve the effects of improving production capacity, increasing filtration area, overcoming costs and affecting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Embodiment, a bagless corrugated filter plate, the filter plate is made of 316L stainless steel.

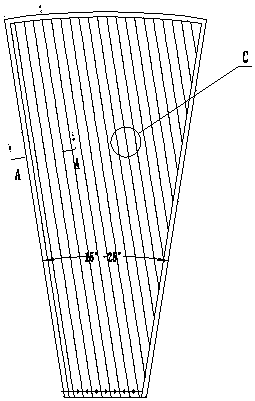

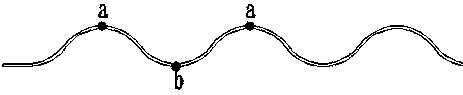

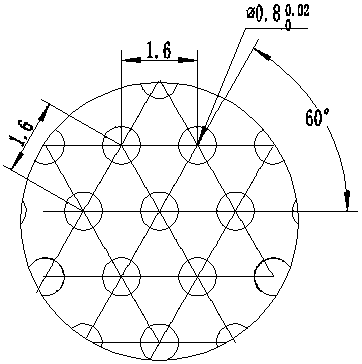

[0012] The filter plate is a fan-shaped plate, and a plurality of holes of Φ0.8mm are evenly opened on the fan-shaped plate, and the distance between adjacent holes is 1.6mm. The vertical distance between them is 8-12mm, the distance between two adjacent peaks a is 32-40mm, and the central angle corresponding to the outer circular arc of the wave-shaped fan-shaped plate is between 15°-25°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com