Valve core

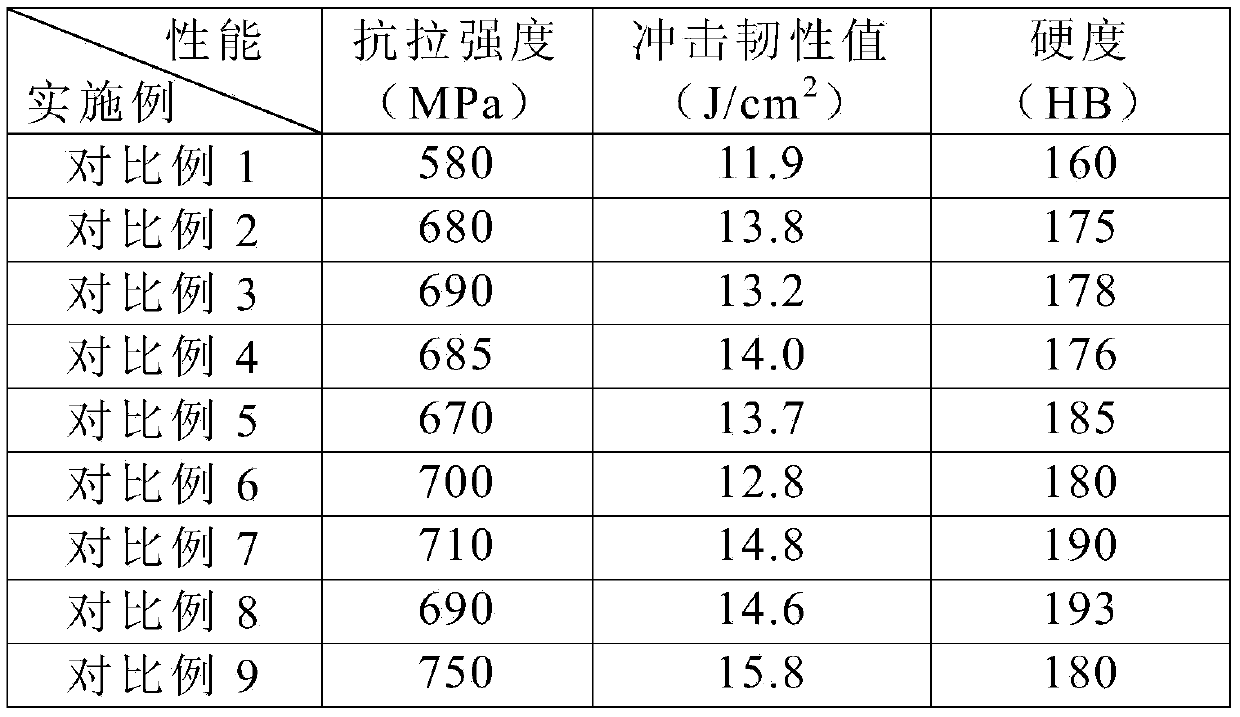

A valve core and main body technology, applied in control valves, functional valve types, engine components, etc., can solve problems such as metal valve cores are easy to corrode, rubber valve cores are easy to age, and tire temperature rises, so as to reduce corrosion sensitivity and improve Exfoliation corrosion resistance, corrosion rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

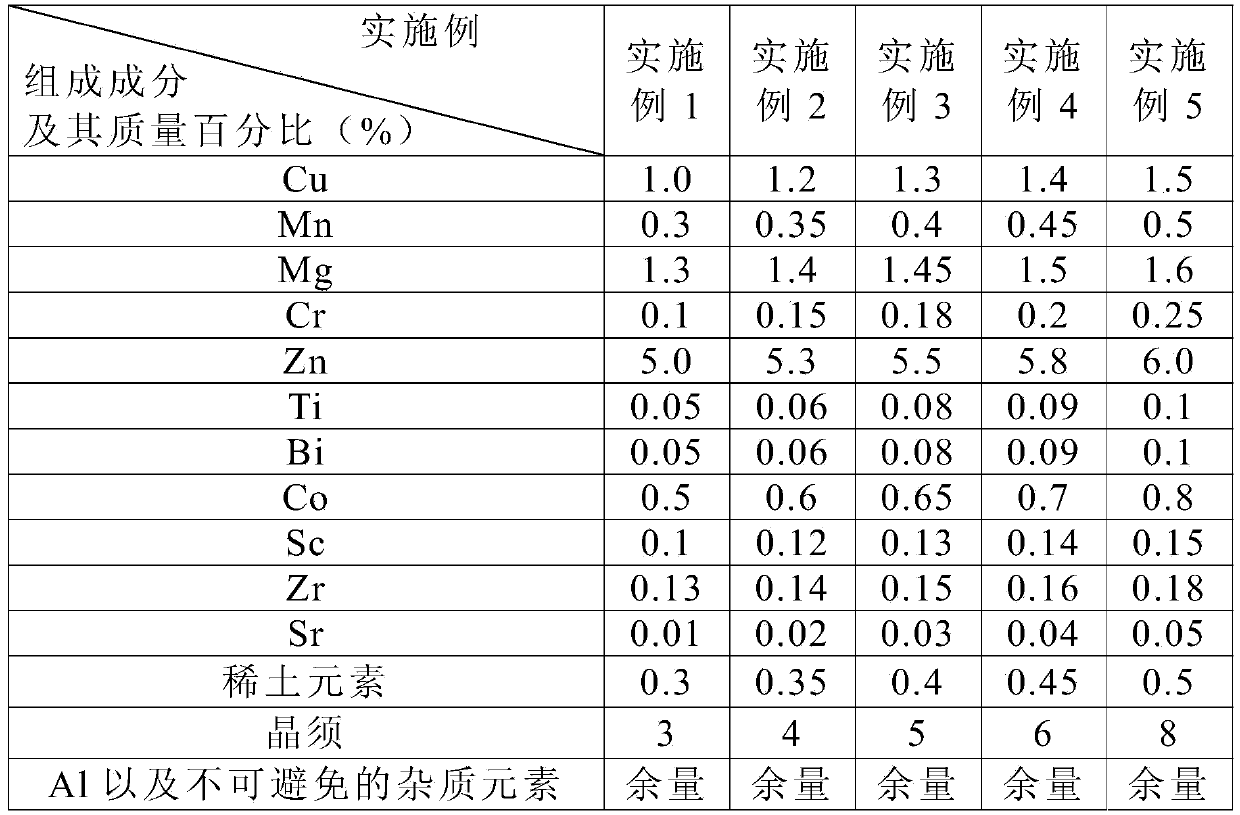

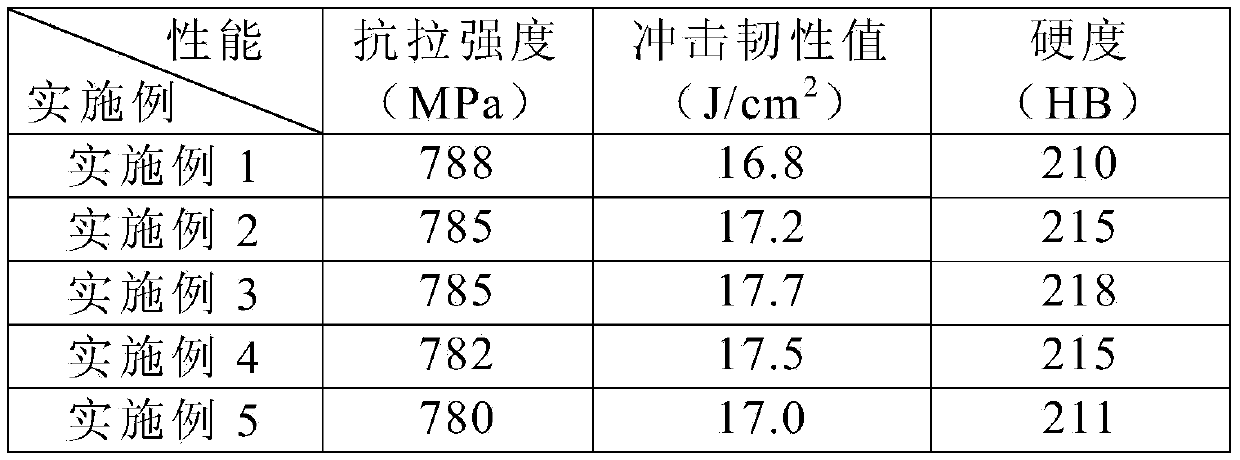

[0037] First, according to the composition and mass percentage of Example 1 in Table 1, the ingredients are formulated, wherein the rare earth element is La, and the whiskers are aluminum borate whiskers. Then the raw materials are smelted and cast into aluminum rods, the casting temperature is 700°C, and the casting speed is 80mm / min. Subsequently, the cast aluminum rod was subjected to homogenization annealing, the temperature of the homogenization annealing was 450° C., and the holding time was 12 hours. The aluminum rod is then extruded at a temperature of 400°C.

[0038] Secondly, the extruded aluminum rod is processed into a valve core blank through a multi-station cold heading car.

[0039] Finally, the valve core blank is subjected to solution treatment, and the solution treatment is a gradient solution treatment. It is kept at 460°C for 5 minutes, when the temperature is raised to 470°C, it is kept for 5 minutes, and when the temperature is raised to 480°C, it is kep...

Embodiment 2

[0041]First, according to the composition and mass percentage of Example 2 in Table 1, the ingredients are formulated, wherein the rare earth element is Ce, and the whiskers are aluminum borate whiskers. Then the raw materials are smelted and cast into aluminum rods, the casting temperature is 710° C., and the casting speed is 83 mm / min. Subsequently, the cast aluminum rod was subjected to homogenization annealing, the temperature of the homogenization annealing was 460° C., and the holding time was 11 hours. The aluminum rod is then extruded at a temperature of 410°C.

[0042] Secondly, the extruded aluminum rod is processed into a valve core blank through a multi-station cold heading car.

[0043] Finally, the valve core blank is subjected to solution treatment, and the solution treatment is gradient solution treatment. It is kept at 460°C for 6 minutes, when the temperature is raised to 470°C, it is kept for 6 minutes, and when the temperature is raised to 480°C, it is kep...

Embodiment 3

[0045] First, according to the composition and mass percentage of Example 3 in Table 1, the ingredients are formulated, wherein the rare earth element is Y, and the whiskers are aluminum borate whiskers. Then the raw materials are smelted and cast into aluminum rods, the casting temperature is 720°C, and the casting speed is 85mm / min. Subsequently, the cast aluminum rod was subjected to homogenization annealing, the temperature of the homogenization annealing was 465° C., and the holding time was 11 h. The aluminum rod is then extruded at a temperature of 420°C.

[0046] Secondly, the extruded aluminum rod is processed into a valve core blank through a multi-station cold heading car.

[0047] Finally, the valve core blank is subjected to solution treatment, which is gradient solution treatment, and is kept at 460°C for 8 minutes, when the temperature is raised to 470°C, it is kept for 8 minutes, and when the temperature is raised to 480°C, it is kept for 13 minutes. Then per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com