thick hot rolled sheet steel with 450MPa grade yield strength and manufacturing method thereof

A technology of hot-rolled steel sheet and yield strength, applied in the field of hot-rolled steel sheet with a yield strength of 450MPa thick specification and its manufacturing field, can solve the problems of increased cost and increased energy consumption of hot-rolling equipment, and achieves reduction of alloy cost, improvement of elongation, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

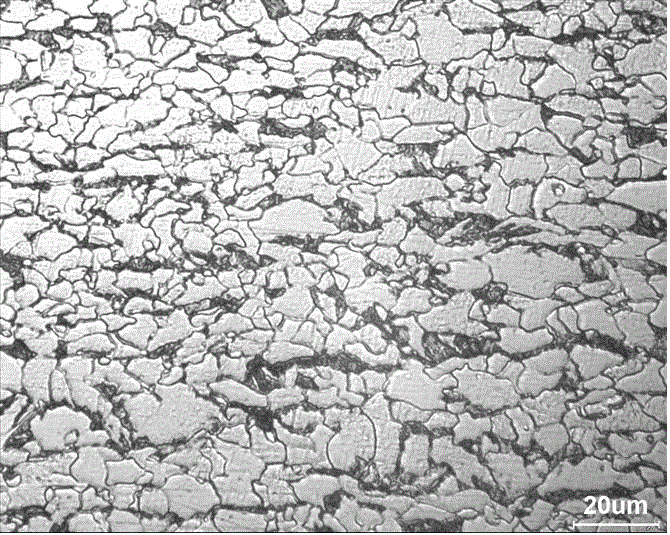

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with Examples 1-4.

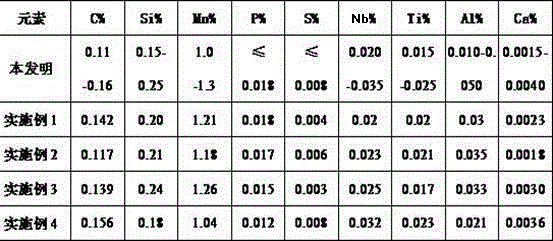

[0036] Table 1 Chemical composition of the present invention (% by weight), the balance is Fe and unavoidable impurities.

[0037]

[0038] According to the requirements of the material composition design of the present invention, pre-desulfurization of molten iron is adopted, top-bottom combined blowing of converter, Ar blowing station (or LF furnace) ensures bottom blowing Ar, continuous casting is blown Ar for protection casting, and casting into continuous casting slab.

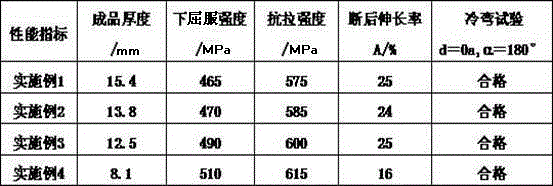

[0039] After the continuous casting slab is reheated by the heating furnace, it is rolled on a fully continuous hot rolling mill. The process control parameters are shown in Table 2. First, rough rolling is carried out through the rough rolling mill. , the intermediate billet is curled by the hot coil box and then unfolded for finish rolling. After controlled rolling by the finish rolling tandem rolling u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com