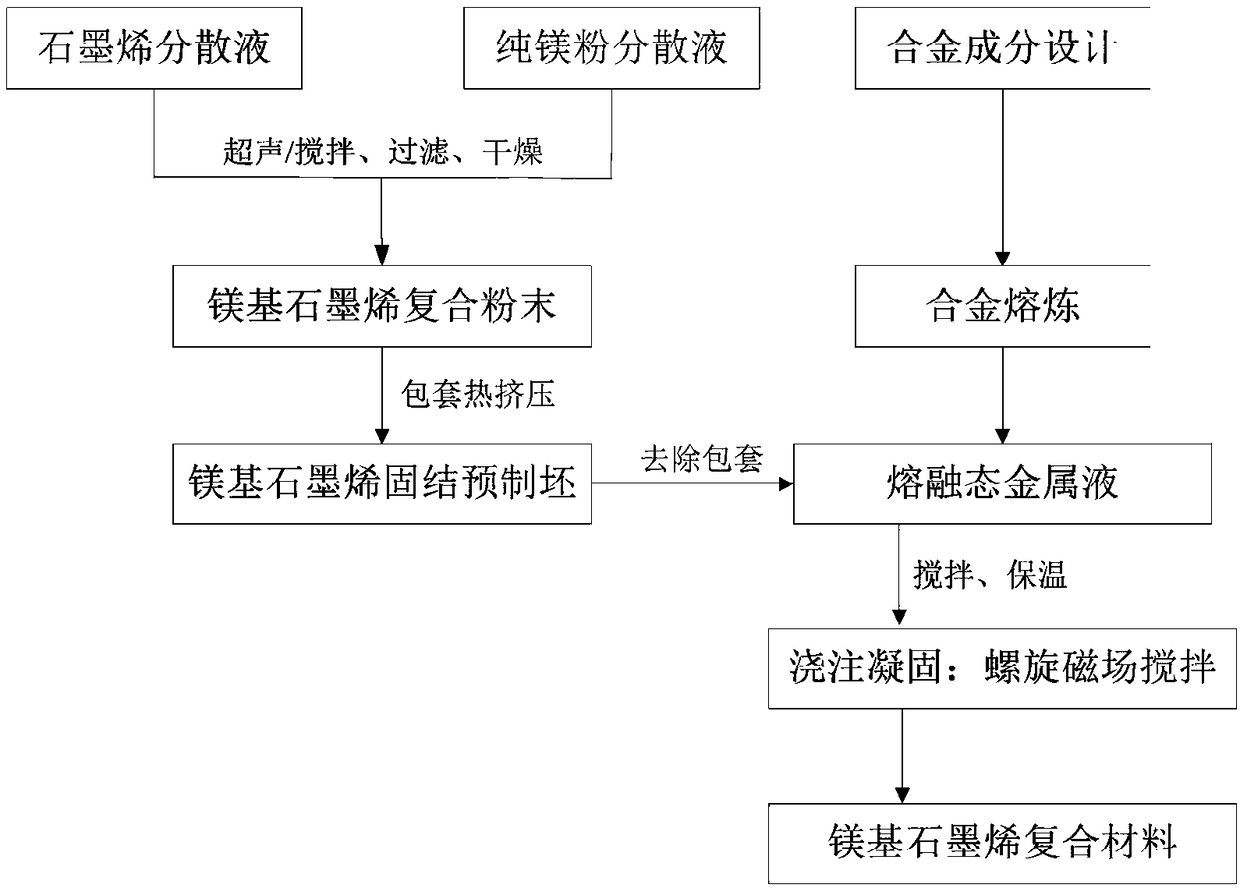

A kind of preparation method of magnesium-based graphene composite material

A composite material and graphene technology, applied in the field of metal matrix composite materials, can solve problems such as poor lubricity, poor interface bonding, uneven dispersion of graphene and magnesium alloys, etc., to reduce casting defects, refine grains, and be simple and easy Realize the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

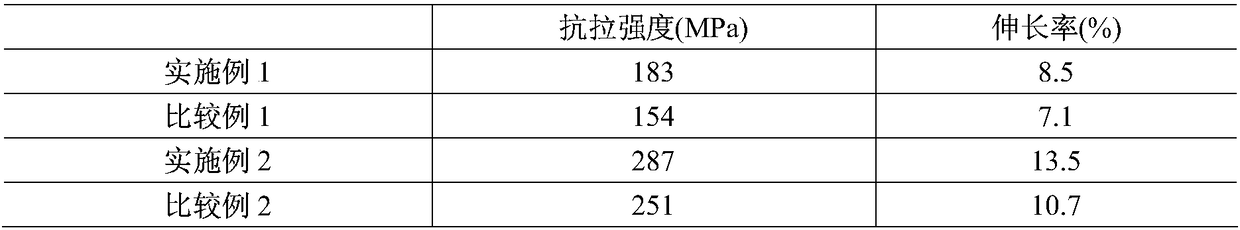

Embodiment 1

[0032] A kind of preparation method of magnesium-based graphene composite material, carries out according to the following steps:

[0033] (1) Get 200mg graphene powder and join in 300ml dehydrated ethanol solution, through ultrasonic treatment of 400W, 40min, make the graphene ethanol solution that concentration is 0.67mg / ml and disperse uniformly;

[0034] (2) In a vacuum glove box, take 99.8g of metal magnesium powder with a particle size of 325 meshes, add it to 100ml of absolute ethanol solution, and perform ultrasonic treatment and mechanical stirring for 15min; Graphene ethanol solution, the time length of ultrasonic treatment and mechanical stirring is 2h, obtains the graphene / magnesium powder mixed solution that disperses uniformly;

[0035] (3) The mixed solution prepared in step (2) is filtered, then vacuum-dried, and dried at 35° C. for 6 hours to obtain a magnesium-based graphene composite powder.

[0036] (4) Transfer the composite powder prepared in step (3) to...

Embodiment 2

[0042] A kind of preparation method of magnesium-based graphene composite material, carries out according to the following steps:

[0043] (1) Get 500mg graphene powder and join in 400ml dehydrated ethanol solution, through ultrasonic treatment of 600W, 30min, make the graphene ethanol solution that concentration is 1.25mg / ml and evenly dispersed;

[0044] (2) Take 99.5g of magnesium metal powder with a particle size of 400 mesh in a vacuum glove box, add it to 100ml of absolute ethanol solution, and perform ultrasonic treatment and mechanical stirring for 15min; Graphene ethanol solution, the time length of ultrasonic treatment and mechanical stirring is 2h, obtains the graphene / magnesium powder mixed solution that disperses uniformly;

[0045] (3) The mixed solution prepared in step (2) was filtered, then vacuum-dried, and dried at 45° C. for 5 hours to obtain a magnesium-based graphene composite powder.

[0046] (4) Transfer the composite powder prepared in step (3) to a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com