Preparation method of Cu-Nb-Ag ternary multi-core composite wire

A cu-nb-ag, composite wire technology, applied in the field of metal matrix composite materials, can solve the problems of affecting the electrical conductivity of materials, limiting the electrical conductivity of materials, etc., and achieve the effect of improving the overall electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

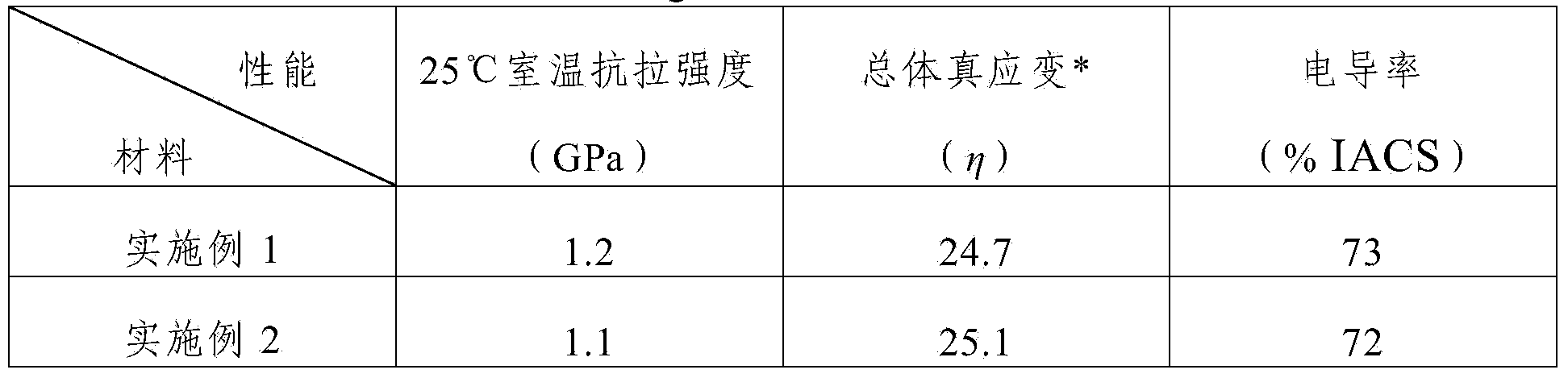

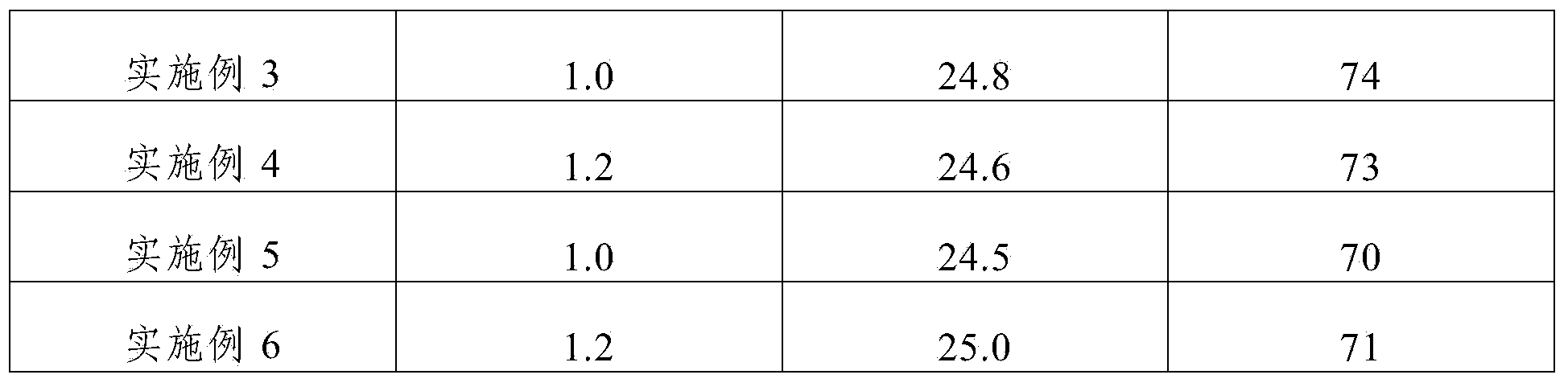

Embodiment 1

[0018] In the Cu-Nb-Ag ternary multi-core composite wire of this embodiment, the volume percentage of Nb is 21.5%, the volume percentage of Ag is 15.9%, and the balance is Cu.

[0019] The preparation method of the Cu-Nb-Ag ternary multi-core composite wire of this embodiment includes the following steps:

[0020] Step 1. Put a single Ag rod with a diameter of 30mm into a Nb tube with an outer diameter of 46mm, an inner diameter of 30mm and a mass purity of ≥99.9%, and then put them together in the first anaerobic tube with an outer diameter of 60mm and an inner diameter of 46mm. Inside the Cu sheath, a Cu-Nb-Ag ternary single-core composite sheath is obtained;

[0021] Step 2: Use a vacuum electron beam welder to seal both ends of the Cu-Nb-Ag ternary single-core composite sheath described in Step 1 by vacuum electron beam welding;

[0022] Step 3. Keep the Cu-Nb-Ag ternary single-core composite sheath welded in step 2 for 2 hours at a temperature of 700°C and then extrude, keep the ...

Embodiment 2

[0030] In the Cu-Nb-Ag ternary multi-core composite wire of this embodiment, the volume percentage of Nb is 18%, the volume percentage of Ag is 10%, and the balance is Cu.

[0031] The preparation method of the Cu-Nb-Ag ternary multi-core composite wire of this embodiment includes the following steps:

[0032] Step 1. Put a single Ag rod with a diameter of 24mm into a Nb tube with an outer diameter of 41mm, an inner diameter of 24mm and a mass purity of ≥99.9%, and then put them together in the first anaerobic with an outer diameter of 60mm and an inner diameter of 41mm Inside the Cu sheath, a Cu-Nb-Ag ternary single-core composite sheath is obtained;

[0033] Step 2: Use a vacuum electron beam welder to seal both ends of the Cu-Nb-Ag ternary single-core composite sheath described in Step 1 by vacuum electron beam welding;

[0034] Step 3. Keep the Cu-Nb-Ag ternary single-core composite sheath welded in step 2 for 3 hours at a temperature of 500°C and then extrude, keep the extrusion ...

Embodiment 3

[0042] In the Cu-Nb-Ag ternary multi-core composite wire of this embodiment, the volume percentage of Nb is 15%, the volume percentage of Ag is 20%, and the balance is Cu.

[0043] The preparation method of the Cu-Nb-Ag ternary multi-core composite wire of this embodiment includes the following steps:

[0044] Step 1. Put a single Ag rod with a diameter of 33.5mm into a Nb tube with an outer diameter of 44mm, an inner diameter of 33.5mm and a mass purity of ≥99.9%, and then put them together in the first with an outer diameter of 60mm and an inner diameter of 44mm. Inside the oxygen-free Cu sheath, a Cu-Nb-Ag ternary single-core composite sheath is obtained;

[0045] Step 2: Use a vacuum electron beam welder to seal both ends of the Cu-Nb-Ag ternary single-core composite sheath described in Step 1 by vacuum electron beam welding;

[0046] Step 3. The Cu-Nb-Ag ternary single-core composite sheath welded in step 2 is kept at a temperature of 600°C for 2.5 hours and then extruded, keepin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com