A Composite Strengthening Method for Thin-Walled Wheels

A roulette, thin-walled technology, applied in the field of composite strengthening of thin-walled roulettes, can solve the problem of failure to give full play to shot peening effects, high-cycle and low-cycle fatigue failure risks, and thin-walled roulette dimensions out of tolerance, etc. problems, to achieve the effect of increasing the range of attitude adjustment, improving the accessibility of shot peening, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The transmission system 5 and the drive motor 6 used are shelf products, and the minimum thickness of the thin-walled disc web is 2.5mm.

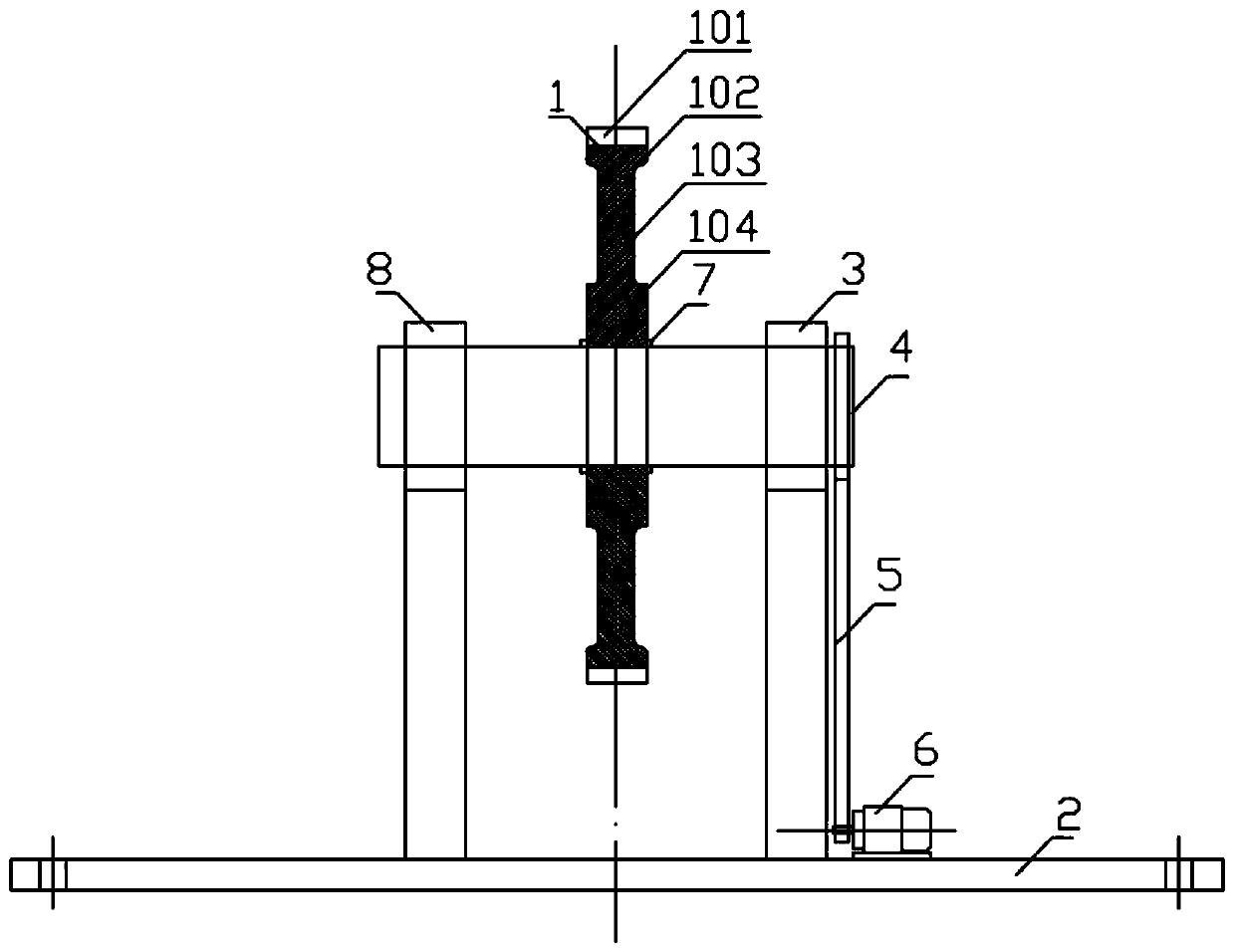

[0050] The shot blasting device comprises a base 2, a right support 3, a left support 8, a main shaft 4, a transmission system 5, a driving motor 6 and a wedge nail 7. Base 2, right support 3 and left support 8 form a support by welding, the lower end of right support 3 is welded as a whole with the upper surface of base 2, and the lower end of left support 8 is welded as a whole with the upper surface of base 2; The upper end is connected with the right end of the main shaft 4 through a bearing, the upper end of the left bracket 8 is connected with the left end of the main shaft 4 through a bearing, and the main shaft 4 is interference fit with the inner ring of the bearing and can be disassembled; the upper end of the transmission system 5 is connected with the main shaft The right end of 4 is connected, and the lower end of the tr...

Embodiment 2

[0063] The minimum thickness of thin-walled disc webs is 10mm.

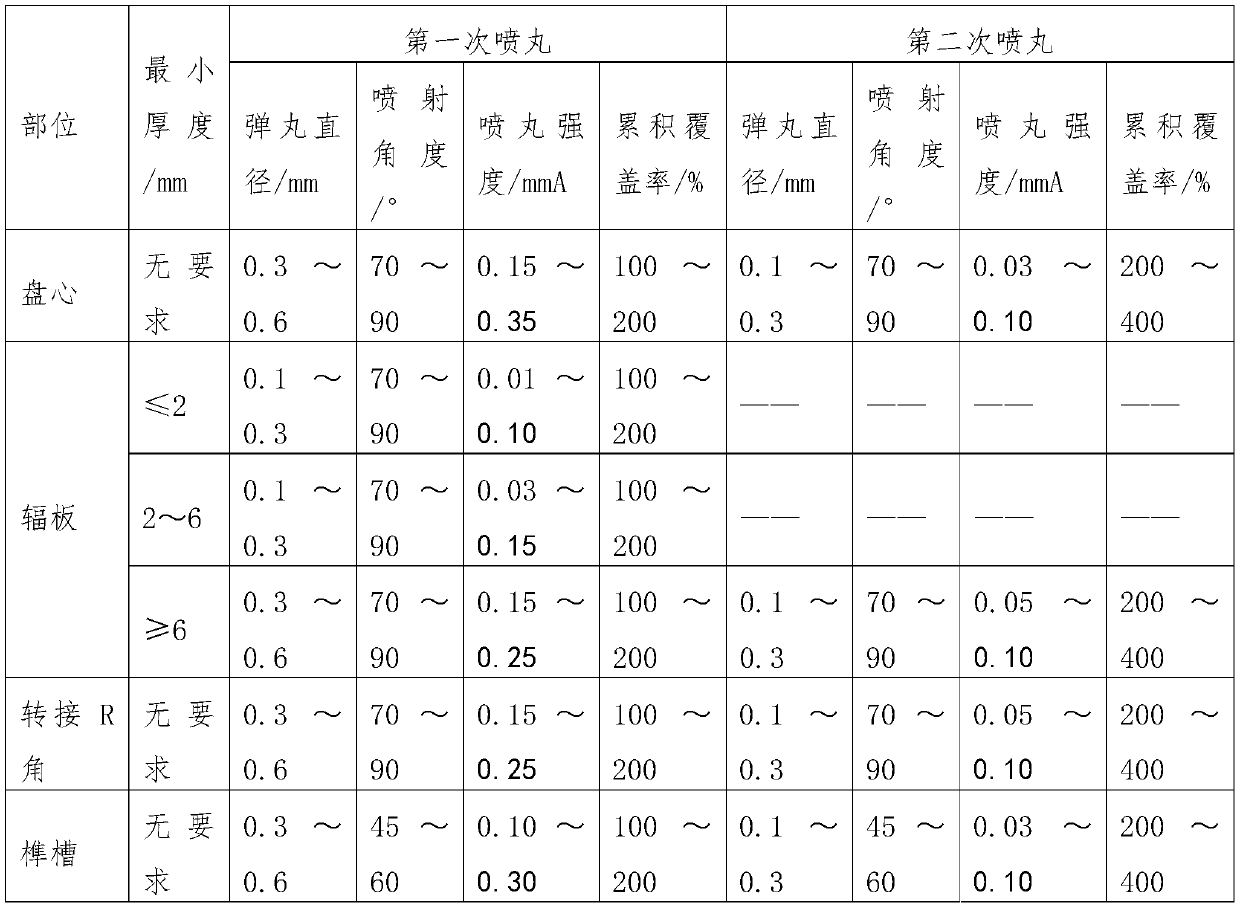

[0064] Table 1 Composite shot peening process parameters

[0065]

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com