A Roller of Planetary Roller Screw Pair for Improving Roller Force

A planetary roller and screw pair technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems affecting the force of the rollers and transmission accuracy, waste of materials, difficulty in ensuring the consistency of the rollers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

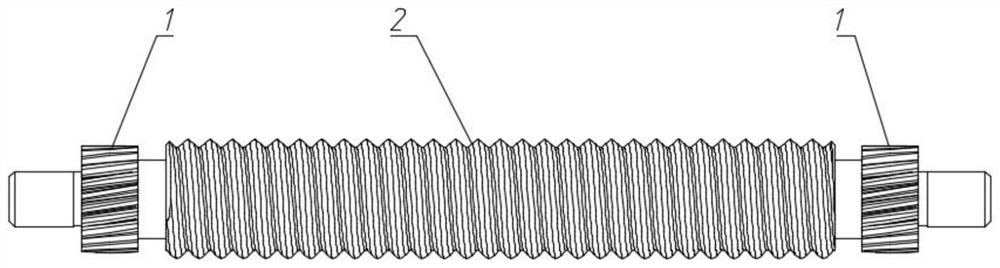

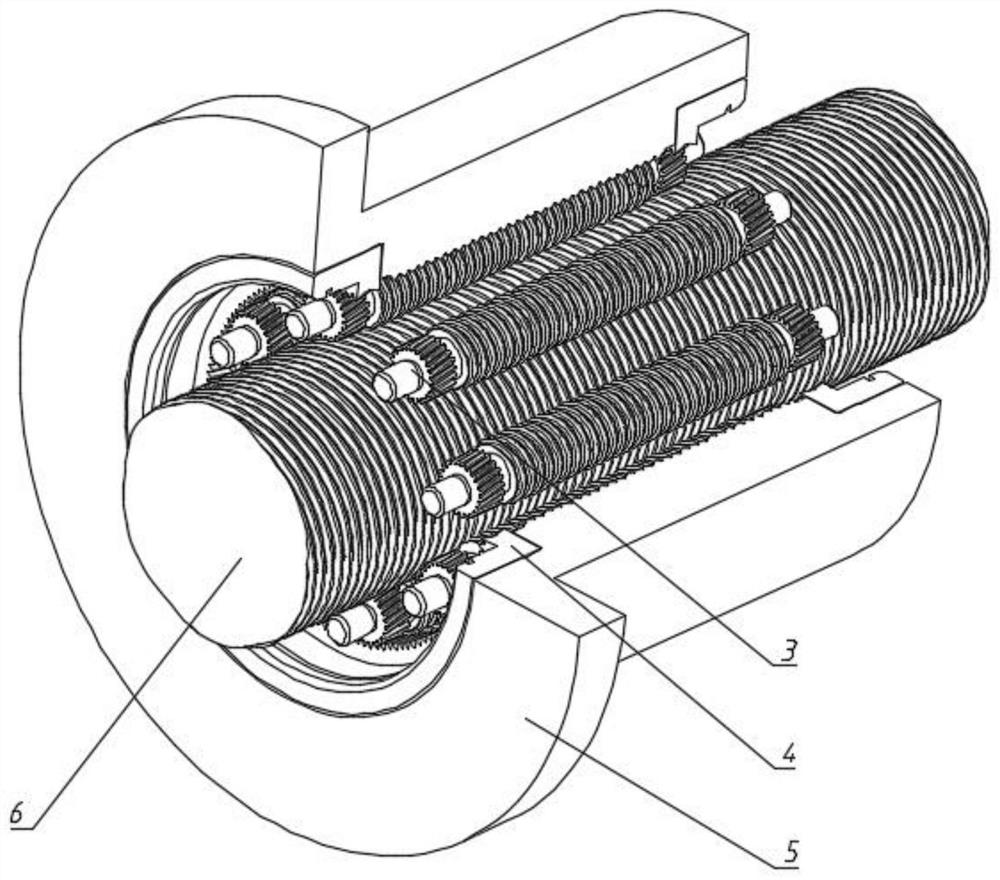

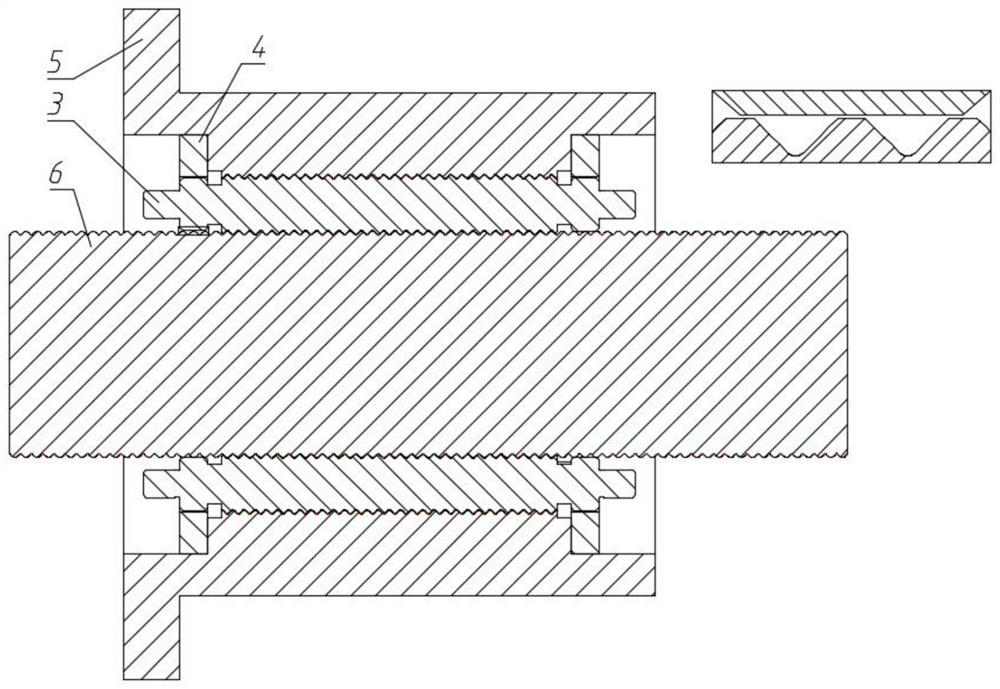

[0043] Embodiment 1, with reference to figure 1 , figure 2 and image 3 , the radius of the addendum circle of the gear segment structure 1 at both ends of the roller 3 is Its relationship with the first leading screw 6 is: Where a is the center distance between the roller 3 and the first lead screw 6, r a is the thread outer diameter parameter of the first lead screw 6;

[0044] Take the number of teeth of the gear segment structure 1 at both ends and the ring gear 4 as Z respectively 1 ,Z 2 , where Z 2 / Z 1 =i; take the end modulus of the gear segment structure 1 and the inner ring gear 4 at both ends as m t1 、m t2 ,Have Take the end face pressure angles of the gear segment structure 1 at both ends and the inner ring gear 4 as α t1 、α t2 , its value is selected according to the transmission requirements, and m t1 cosα t1 = m t2 cosα t2 ;;Take the helical gear helical angle of the two-end gear segment structure 1 and the inner ring gear 4 as β, which has t...

Embodiment 2

[0054] Embodiment 2, with reference to figure 1 and Figure 4 , in the reverse planetary roller screw, the radius of the addendum circle of the gear segment structure 1 at both ends of the roller 3 is Its relation with the second nut 9 is: Wherein a is the center distance between the roller 3 and the second lead screw 8, is the thread major diameter parameter of the second nut 9;

[0055] Take the number of teeth of gear segment structure 1 and gear 7 at both ends as Z 1 ,Z 3 , where Z 3 / Z 1 =i; take the end modulus of the gear segment structure 1 and the gear 7 at both ends as m t1 、m t3 ,Have Take the end face pressure angles of gear segment structure 1 and gear 7 at both ends as α t1 、α t3 , its value is selected according to the transmission requirements, and m t1 cosα t1 = m t3 cosα t3 ; Take the helix angle of the gear segment structure 1 at the two ends of the roller and the gear 7 as β, and its direction of rotation is opposite, and the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com