Quick-cooling device for reducing surface crack generation rate of hot-feeding casting blank

A technology of surface crack and generation rate, applied in the field of iron and steel metallurgy, can solve the problems of weakened grain boundary strength, thermal stress crack, insufficient suppression and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

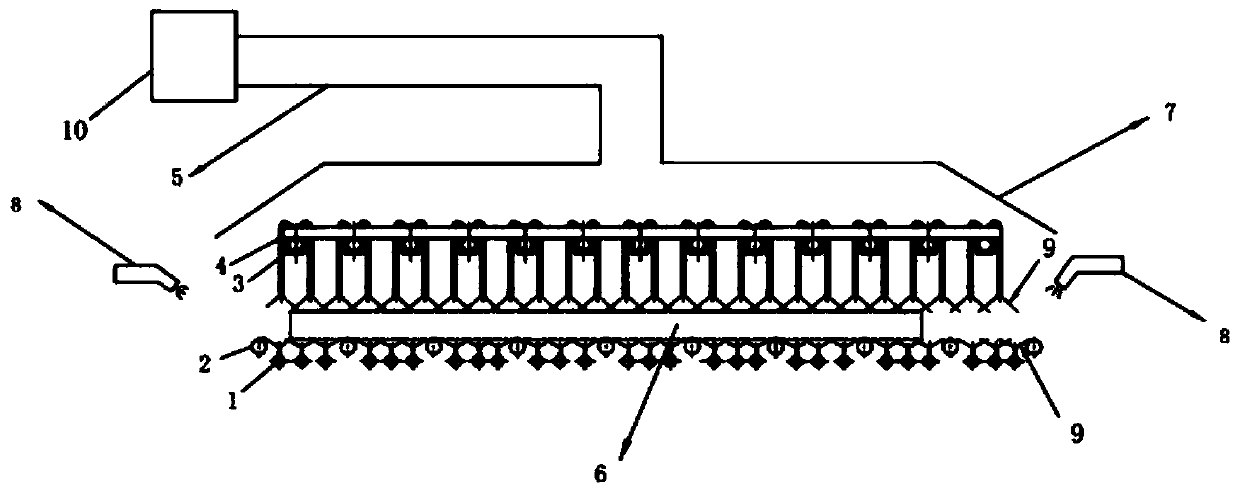

[0069] Such as figure 2 Shown, a kind of fast cooling device that reduces the generation rate of cracks on the surface of the hot casting slab, the fast cooling device includes a round of fast cooling device, and the fast cooling device also includes two rounds of fast cooling device and steam removal cover 7;

[0070] The two-wheel fast cooling device comprises a conveying roller table 2, several rows of upper cooling nozzle groups 3 are set above the conveying roller table 2, and several rows of lower cooling nozzle groups 1 are arranged below the conveying roller table 2. Pyrometer 8 is set respectively at the inlet and outlet of the

[0071] 2-3 rows of upper cooling nozzle groups 3 and lower cooling nozzle groups 1 are evenly arranged between every two conveying rollers of the conveying roller table 2;

[0072] The steam removal cover 7 communicates with the steam collection device 10 through the steam passage 5; the steam removal cover 7 is covered on the two-wheel rap...

Embodiment 2

[0083] Since the 700Mpa grade automobile beam steel needs to add more than 0.1% titanium and more than 0.04% niobium, the content of microalloying elements is high, and the high content of microalloying elements is easy to segregate at the ferrite grain boundary, which increases the cracks on the surface of the slab Sensitivity, the 700Mpa grade automobile frame steel hot casting slab has a high crack occurrence rate during rolling, reaching more than 10%. In order to reduce the 700Mpa automobile frame steel hot delivery slab surface crack generation rate, the following methods are adopted, mainly Including the following two aspects.

[0084] 1. In the continuous casting process, the surface of the slab is subjected to two rounds of rapid cooling by means of a rapid cooling device to refine the grain size of the slab surface, so as to improve the plasticity of the slab surface, including the following technical solutions:

[0085] A: If Figure 5 As shown, a large-flow coolin...

Embodiment 3

[0104] Because the Q690 grade high-strength steel needs to add a large amount of microalloying elements to increase the strength, the sum of the added Nb, V, and Ti mass is greater than 0.1%, and the content of microalloying elements is high. Polymerization, which improves the crack sensitivity of the slab surface, the crack occurrence rate of Q690 level high-strength steel hot-delivery slab is high during rolling, reaching more than 10%. The following methods are proposed, mainly including the following two aspects.

[0105] 1. During the continuous casting process, two rounds of rapid cooling are performed on the surface of the slab to refine the grain size of the slab surface, so as to improve the plasticity of the slab surface, including the following technical solutions:

[0106] A: Arrange large-flow cooling nozzles 13 in the horizontal section adjacent to the straightening section. The horizontal section is 3m long, and a row of large-flow cooling water nozzles 13 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com