Mill base barrel cleaning device

A technology for cleaning devices and color paste buckets, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low efficiency of cleaning machines, achieve good cleaning effects, save costs, and prevent splashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

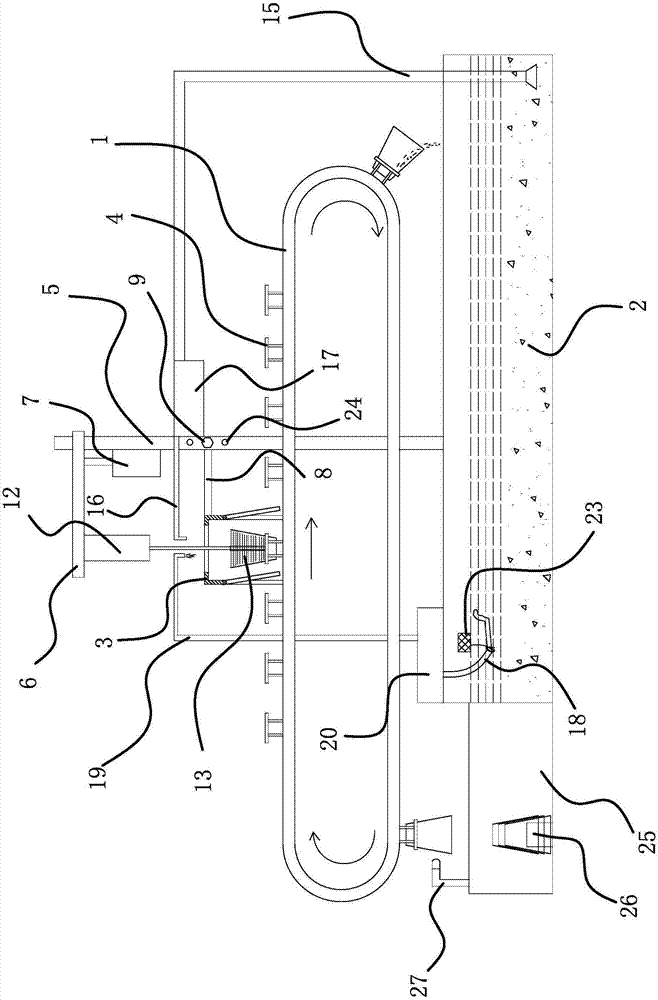

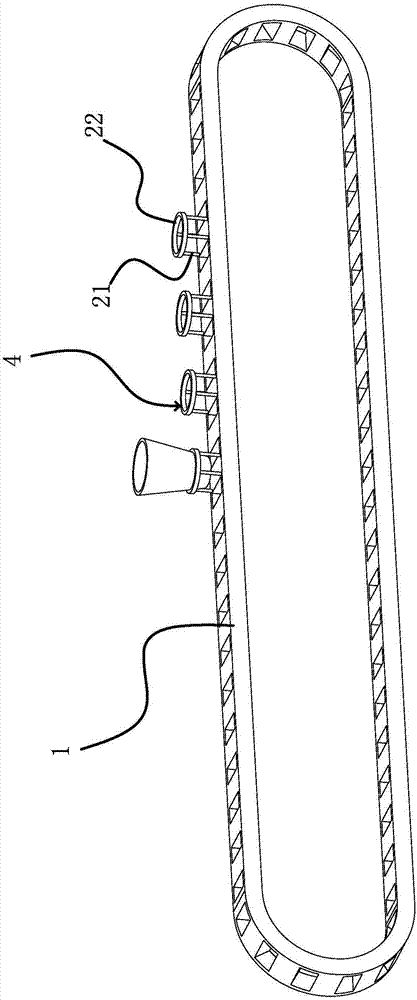

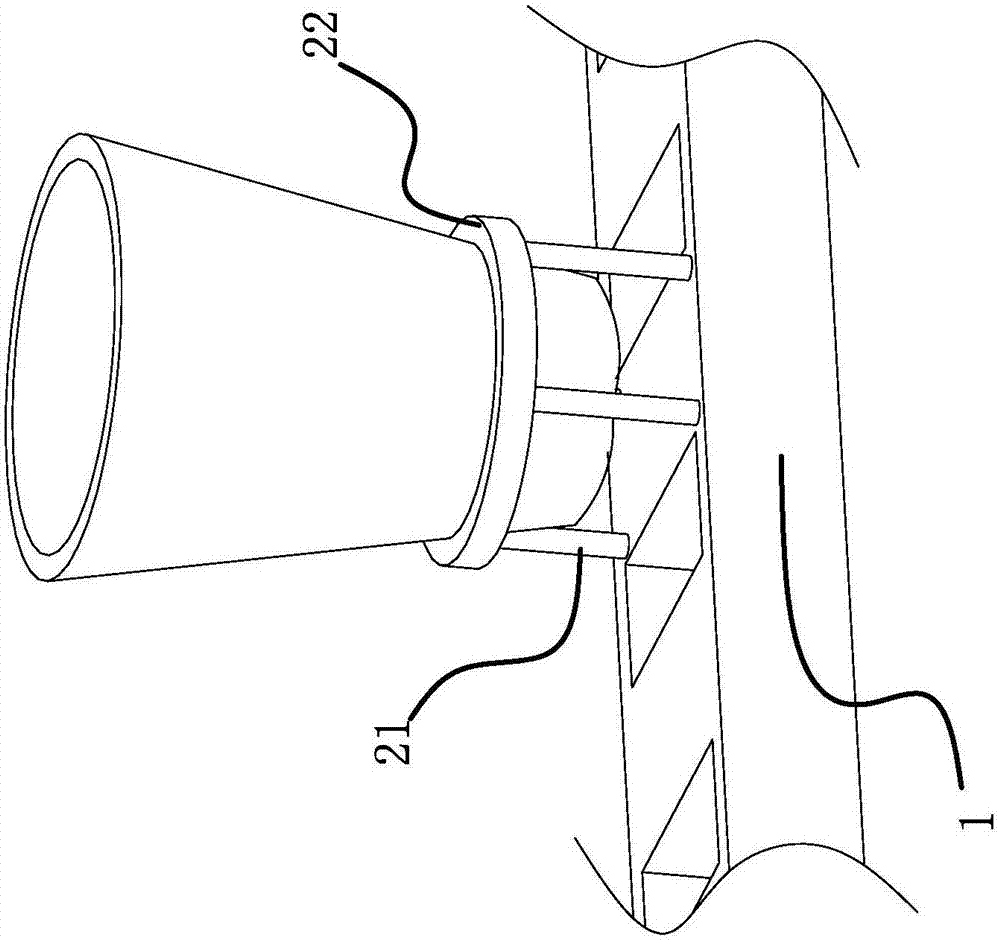

[0025] Such as figure 1 , figure 2 As shown, the cleaning device of the original color paste bucket includes a conveying track 1, a recovery cylinder 2, a protective cover 3, a cleaning assembly, a sand supply assembly, and a cleaning agent assembly. On the conveying crawler belt 1, a number of fixed positions for fixing the color paste bucket are equidistantly fixed. The frame 4 and the recovery cylinder 2 are located directly under the conveyor belt 1. The middle part of the recovery cylinder 2 is vertically fixed with a column 5, and the upper end of the column 5 is covered with a mounting plate 6 that slides up and down along the column 5. Cylinder 7 drives. The lifting cylinder 7 drives the mounting plate 6 to descend, so that the cleaning assembly can be stretched into the protective cover 3 and the color paste bucket. After cleaning is completed, the mounting plate 6 rises, and the color paste bucket moves forward along with the conveyor belt 1.

[0026] The cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com