Drilling machine waste residue collecting device

A collection device and drilling machine technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of scratched skin, no recycling, drilling cuttings fire, etc., to reduce residues, facilitate recycling, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

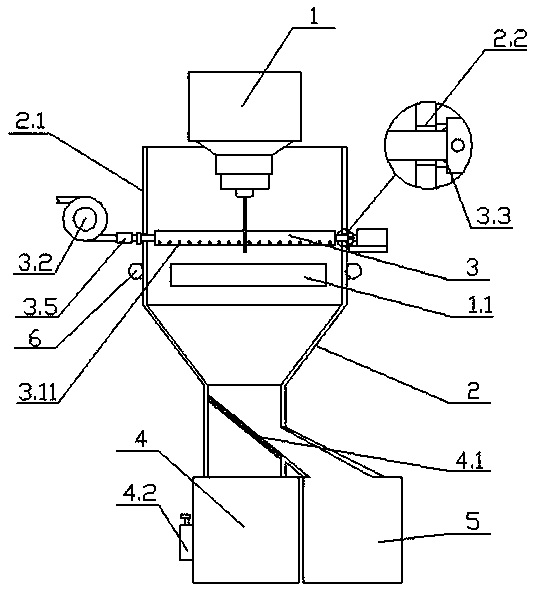

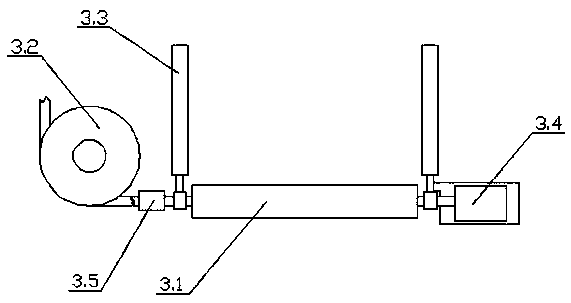

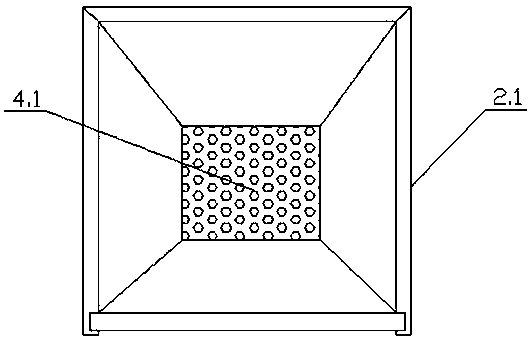

[0010] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0011] Such as Figure 1-3 As shown, a waste residue collection device for a drilling machine 1 includes a drilling machine 1, a material retaining cover 2, an oil box 4 and a drill cuttings box 5, wherein a funnel-shaped material retaining cover 2 (retainer) is provided at the bottom of the drilling machine 1 workbench 1.1 The material cover 2 can be placed directly under the workbench 1.1), and three baffles 2.1 are fixed on the top of the baffle 2 by welding (the three baffles 2.1 are respectively located on the left and right sides of the workbench 1.1 and rear end) and each baffle plate 2.1 is higher than the drill bit of the drilling machine 1, wherein the baffle plate 2.1 positioned at the front is slidingly connected to the other baffle plates 2.1 (there are clips on the inside of the left and right side baffle plates 2.1). Slot, the front baffle 2.1 is snapped into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com