Metal cutting machine

A cutting machine, metal technology, applied in the direction of metal sawing equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reflection, easy to hurt the operator, sparks, etc., to reduce injuries, improve safety and The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

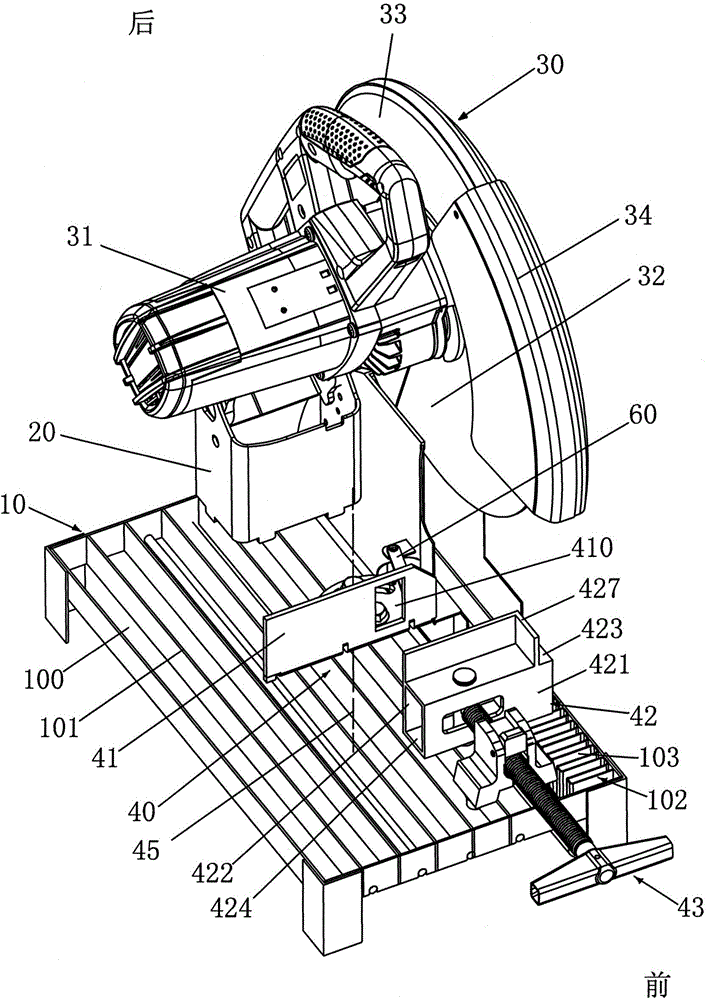

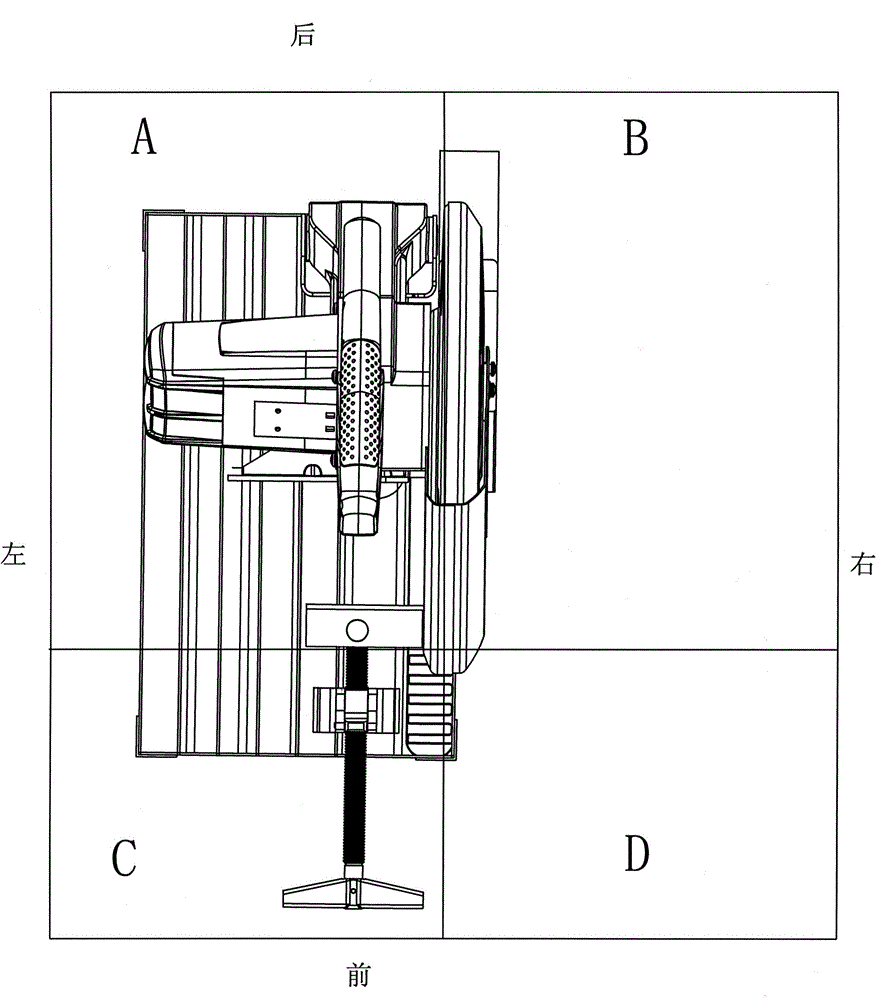

[0013] like figure 1 As shown, the metal cutting machine of the present invention includes a base 10 , a support arm 20 fixedly mounted on the base, and a cutting head 30 pivotally connected to the support arm 20 . The cutting head 30 includes a motor 31 , a blade 32 driven to rotate by the motor 31 , and a fixed shield 33 and a movable shield 34 for covering the blade 32 . The fixed shield 33 is fixedly connected to the cutting head 30 . The cutting head 30 can pivot between the lowest position, which is the working position, where the blade 32 cuts metal, and the highest position, which is the non-working position.

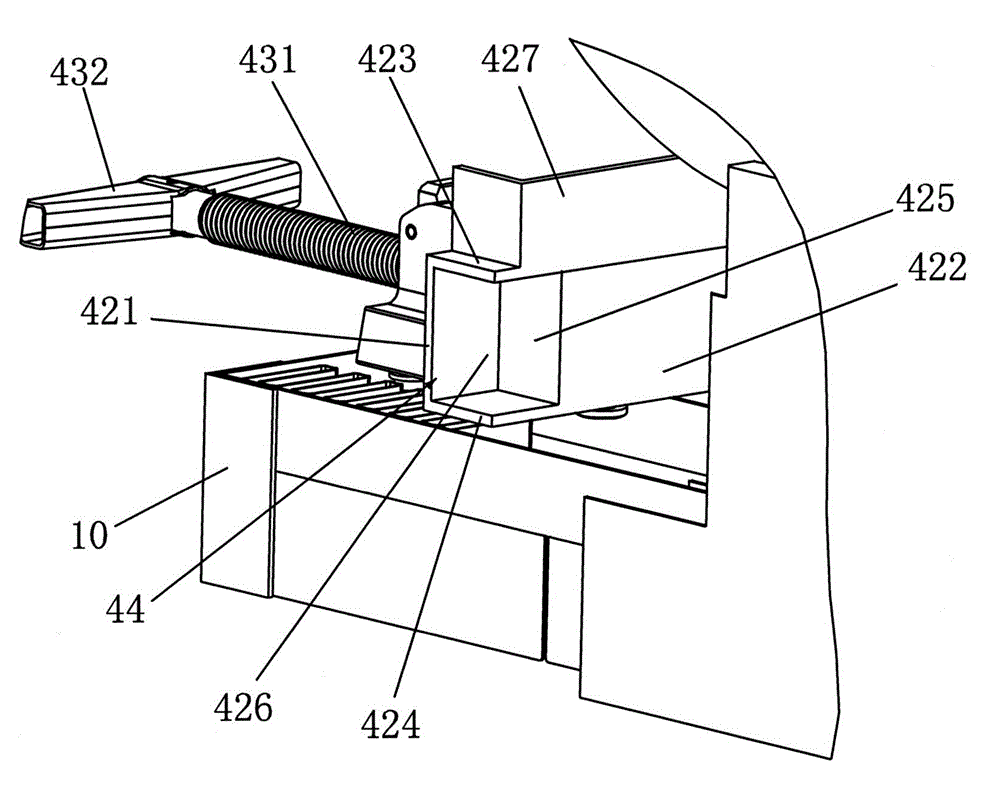

[0014] The base 10 of the metal cutting machine of the present invention is an open base, and the base 10 is provided with a plurality of holes 100 , and the area of the holes 100 accounts for at least 20% of the total area of the upper surface 101 of the base 10 . Such a base has beneficial effects: on the one hand, the sparks that fly to the base 10 gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com