Air lift type bio-nitrification reactor with baffle plate reinforcing internal circulation

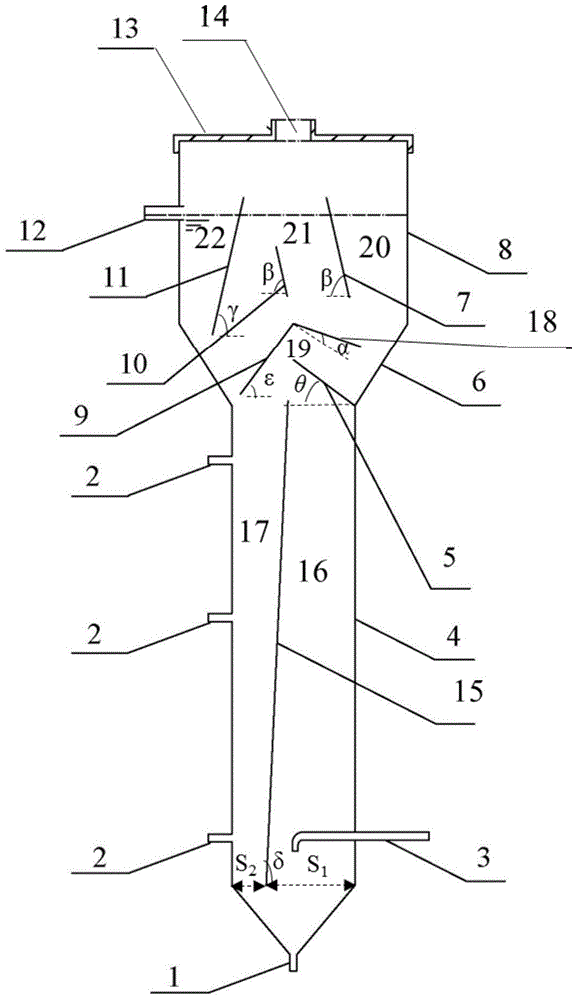

A nitrification reactor and baffle technology, which can be used in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Quality efficiency and oxygen utilization efficiency, good high nitrification performance, ensuring the effect of effluent clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

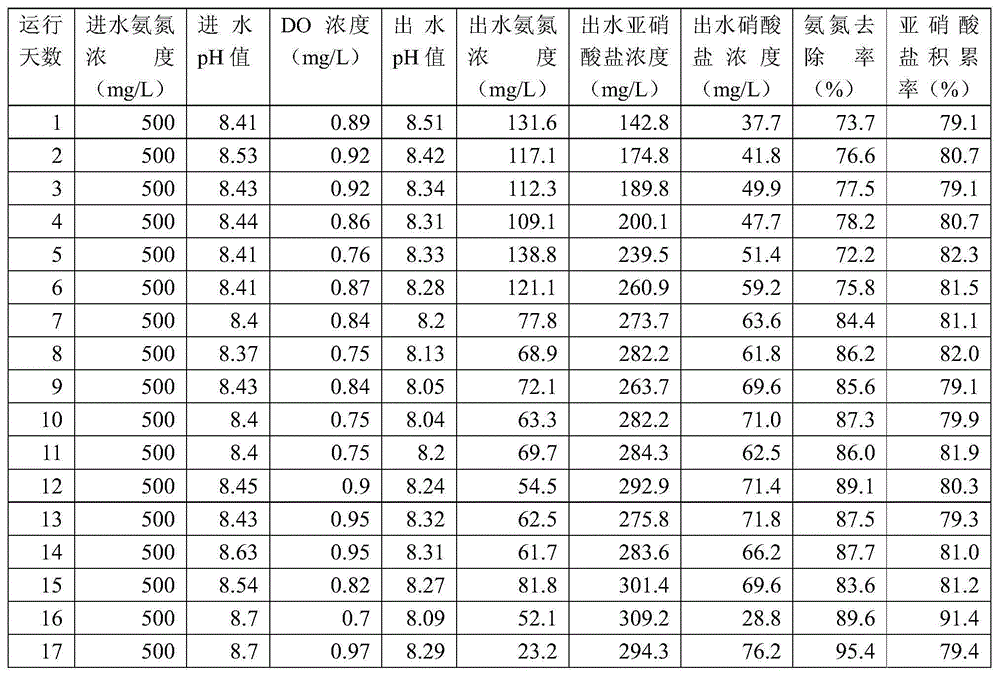

[0032] During the operation of the reactor, keep the concentration of ammonia nitrogen in the influent at 500 mg / L, the concentration of sludge at 4 g / L, the hydraulic retention time at 15.2 hours, and the pH of the influent at 8.4 to 8.7. By adjusting the amount of aeration, the dissolution in the reaction chamber The oxygen (DO) concentration can be stabilized between 0.75 and 0.95. During the 17-day operation, the ammonia nitrogen removal rate of the reactor gradually increased from 73.7% to 95.4%, and the nitrite accumulation rate was maintained at 80% to 90%. Shows good short-range nitrification performance.

[0033] Table 1 Nitrification performance when the influent ammonia nitrogen concentration is 500mg / L

[0034]

Embodiment example 2

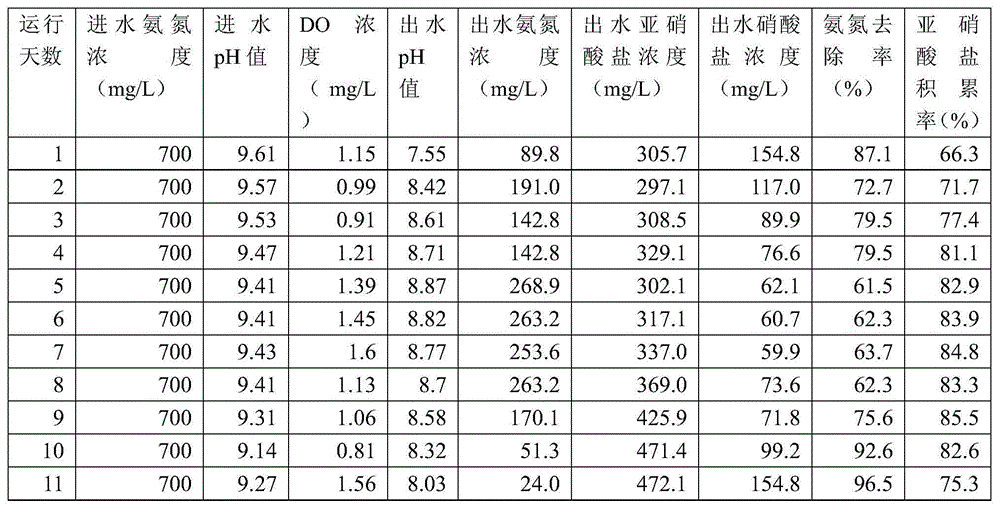

[0036] Keep the concentration of ammonia nitrogen in the influent at 700mg / L, the concentration of sludge at 4g / L, the hydraulic retention time at 15.2h, and the pH of the influent at 9.1-9.6. By adjusting the amount of aeration, the concentration of dissolved oxygen (DO) in the reaction chamber is stabilized at Between 0.8 and 1.6, during 11 days of operation, the ammonia nitrogen removal rate of the reactor gradually increased to 96.5%, and the nitrite accumulation rate still reached 85.5%, and the short-range nitrification performance was very stable.

[0037] Table 2 Nitrification performance when the influent ammonia nitrogen concentration is 700mg / L

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com