Patents

Literature

123results about How to "Improve nitrification capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated closed loop system for industrial water purification

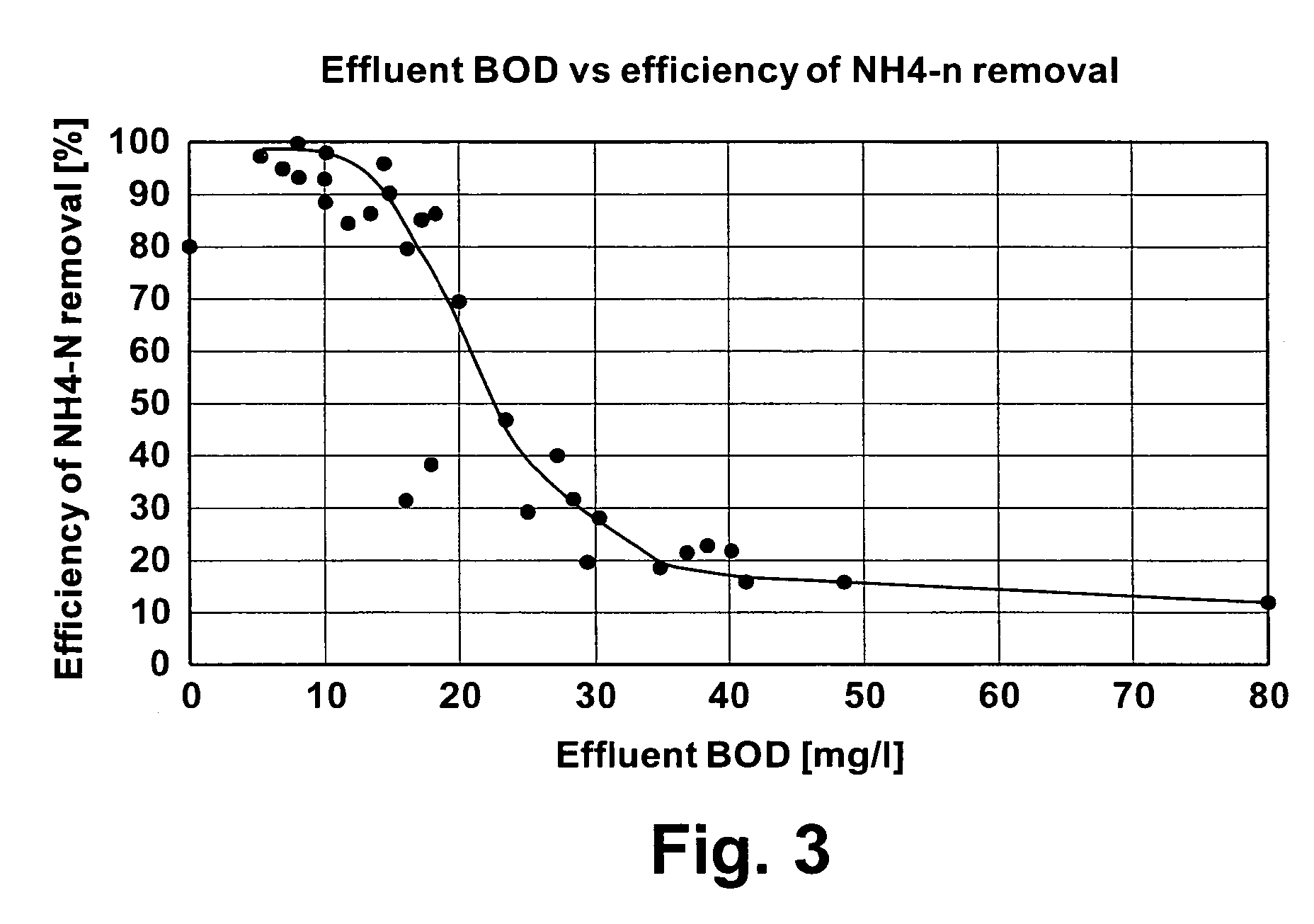

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

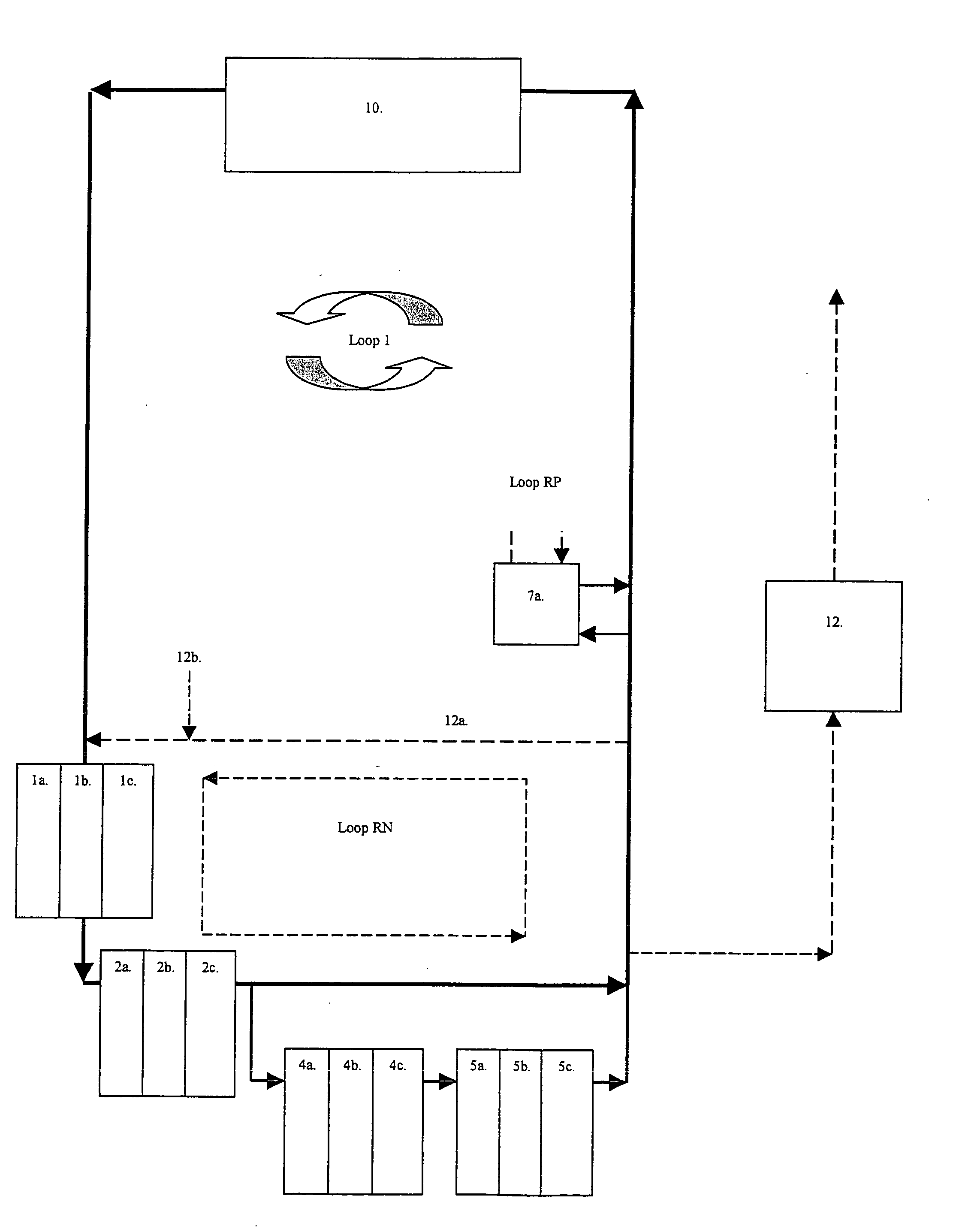

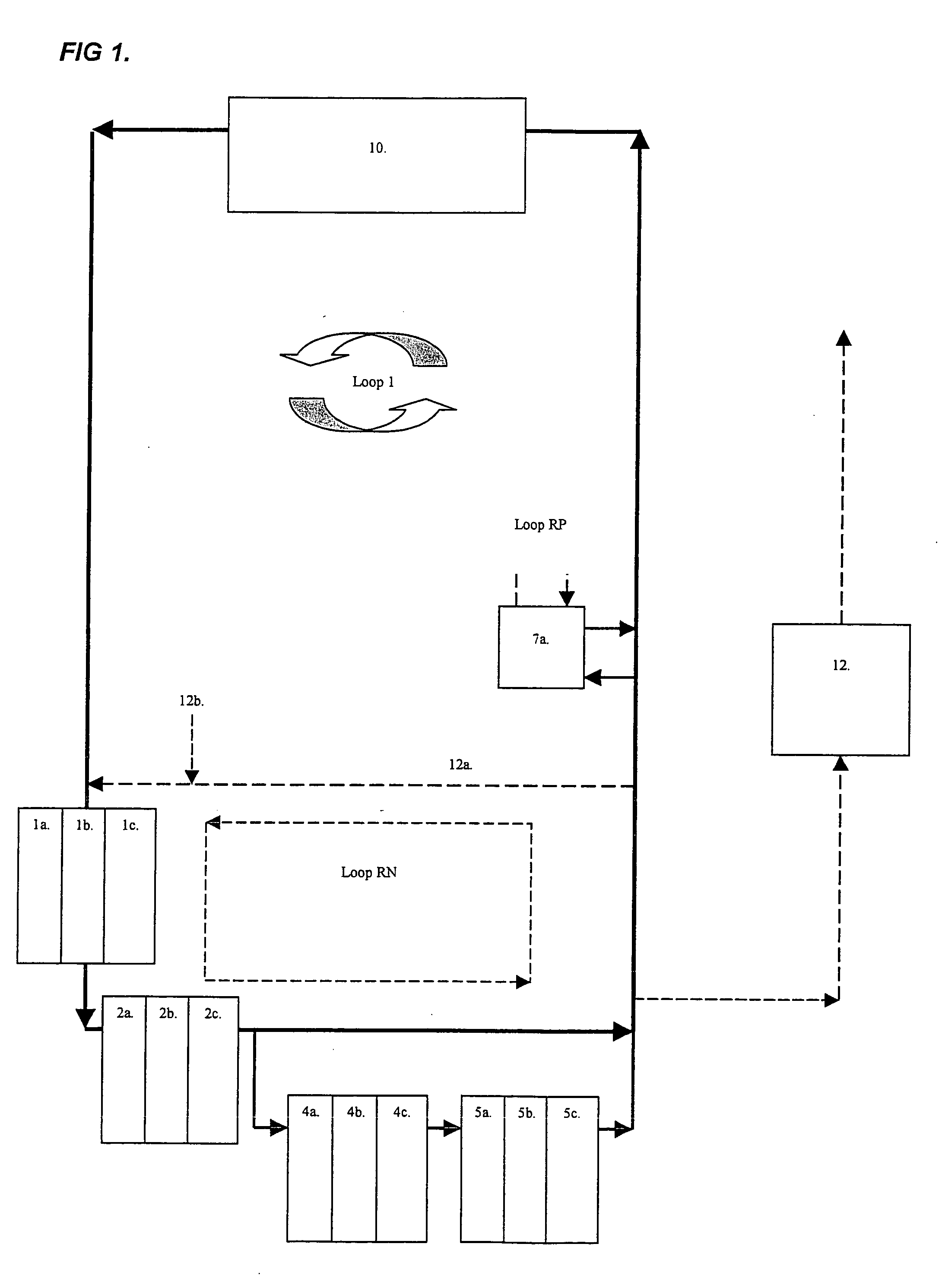

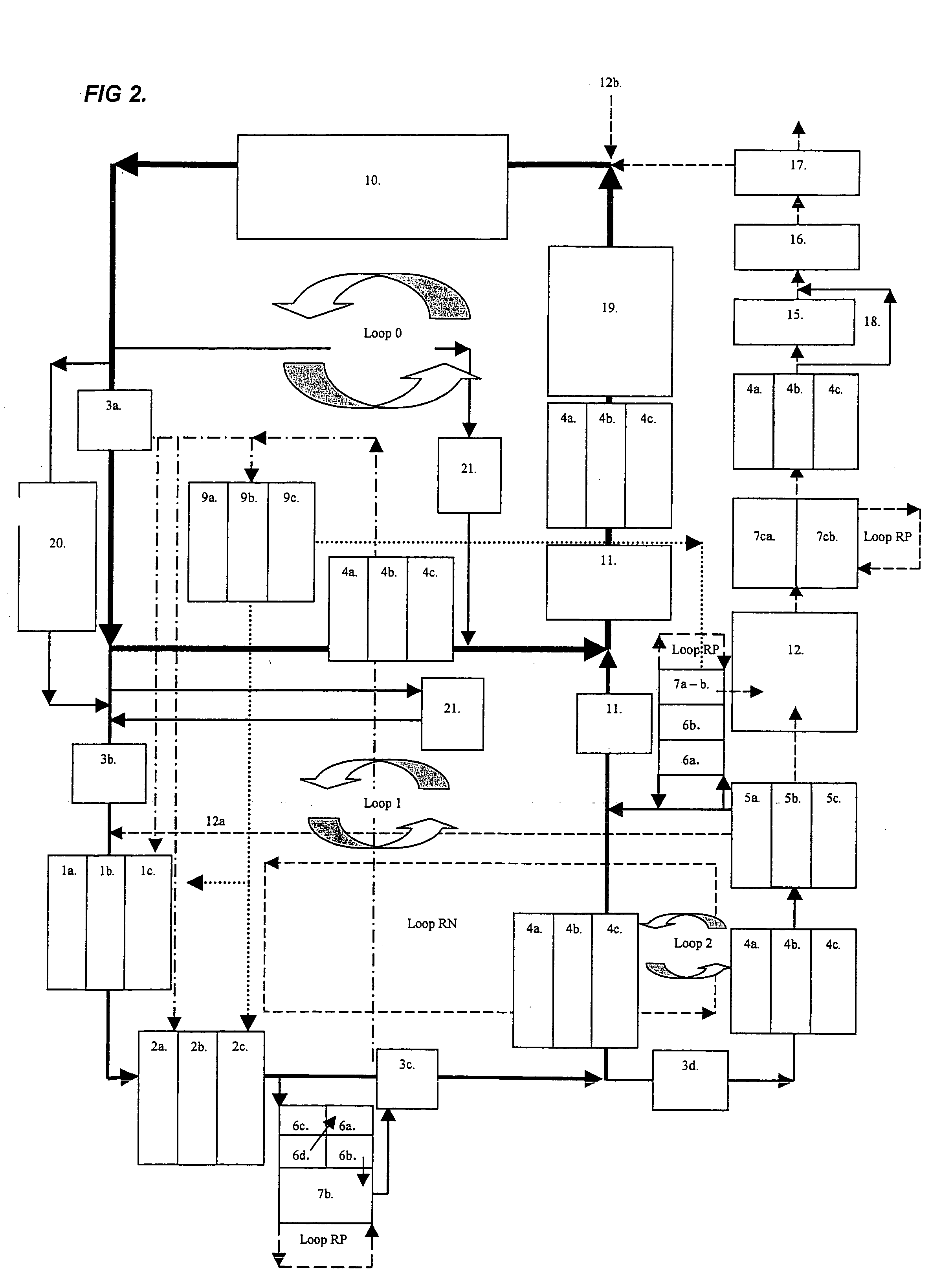

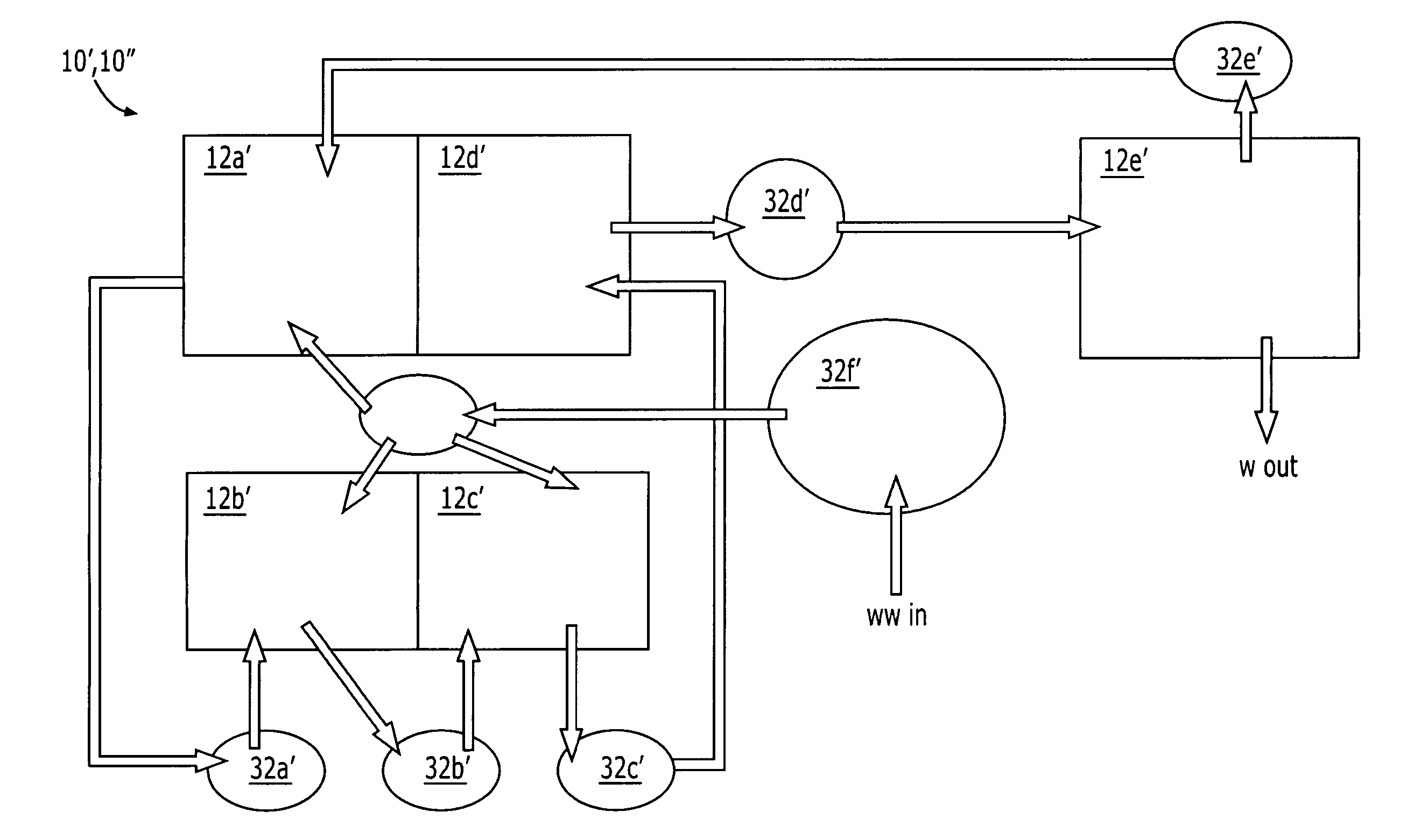

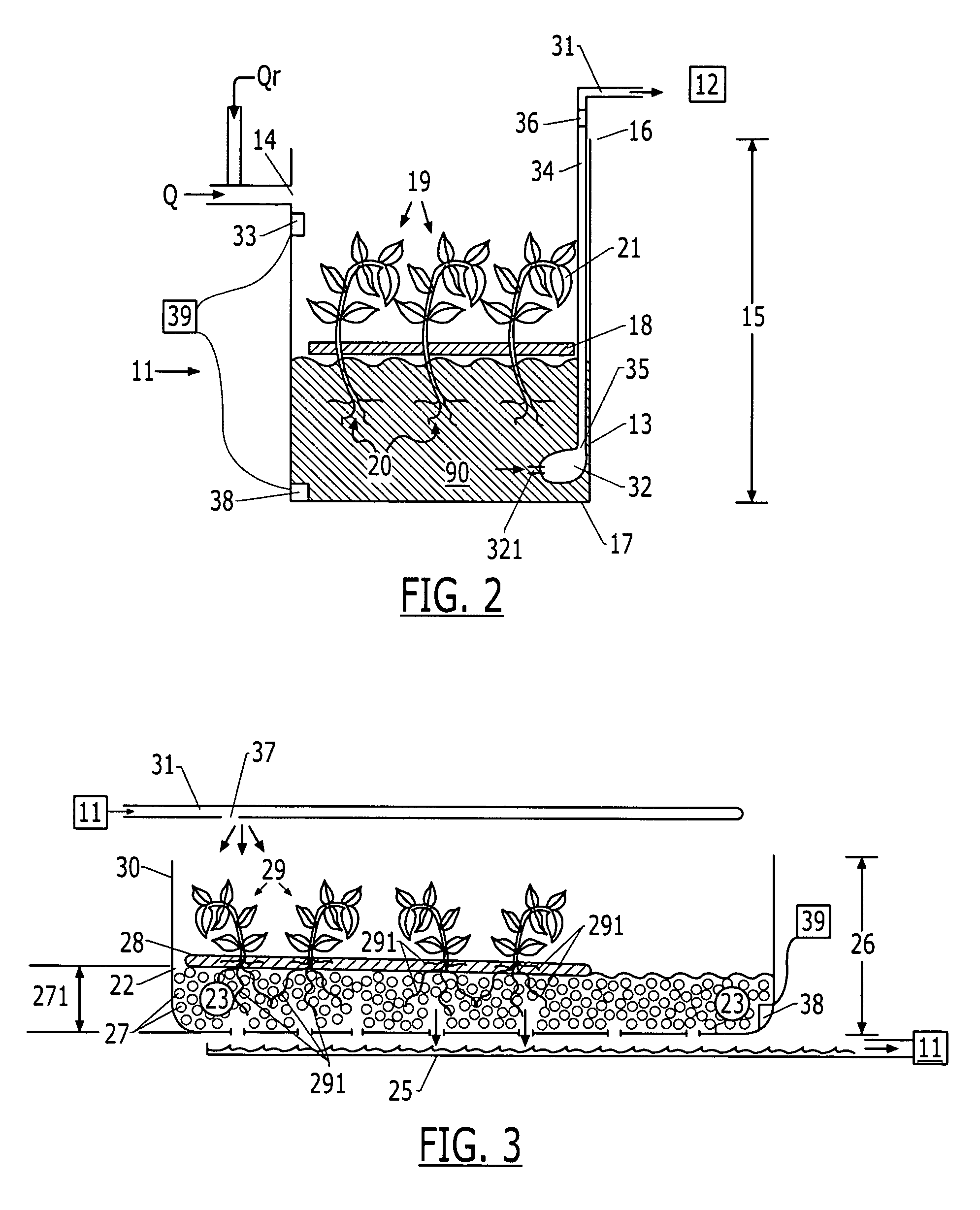

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

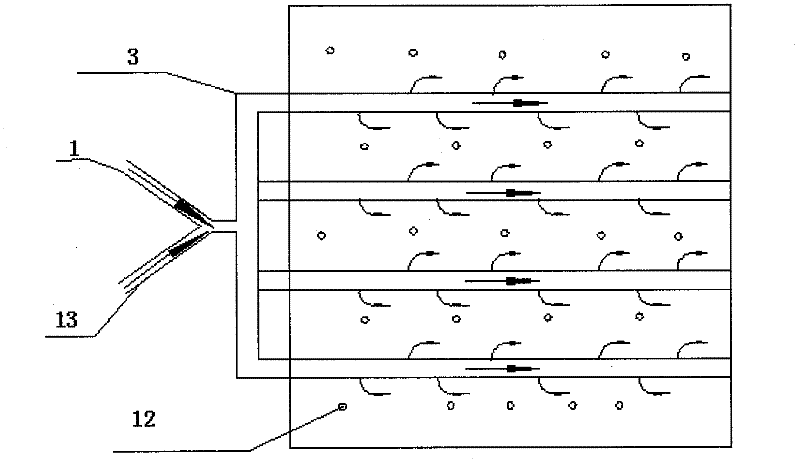

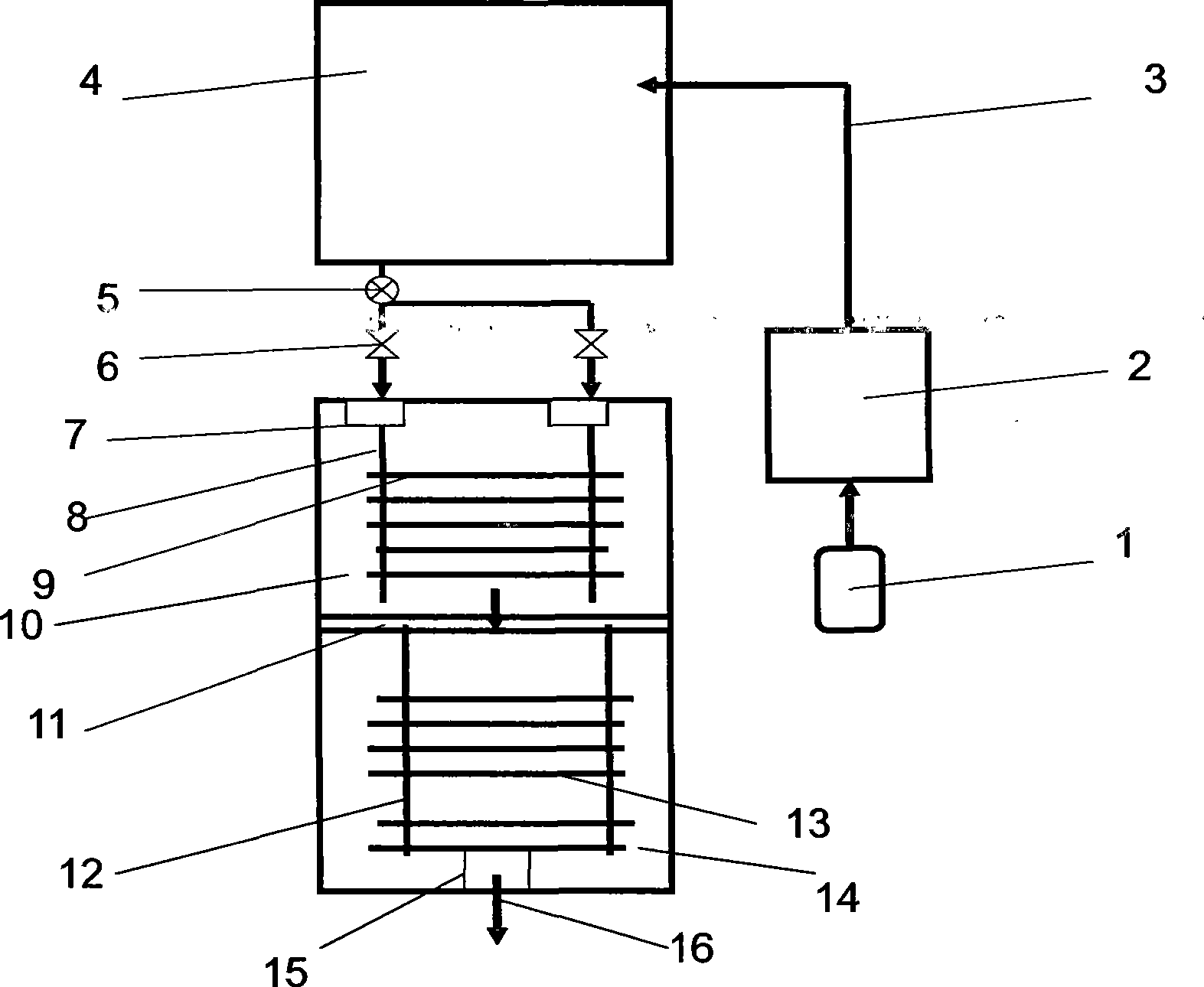

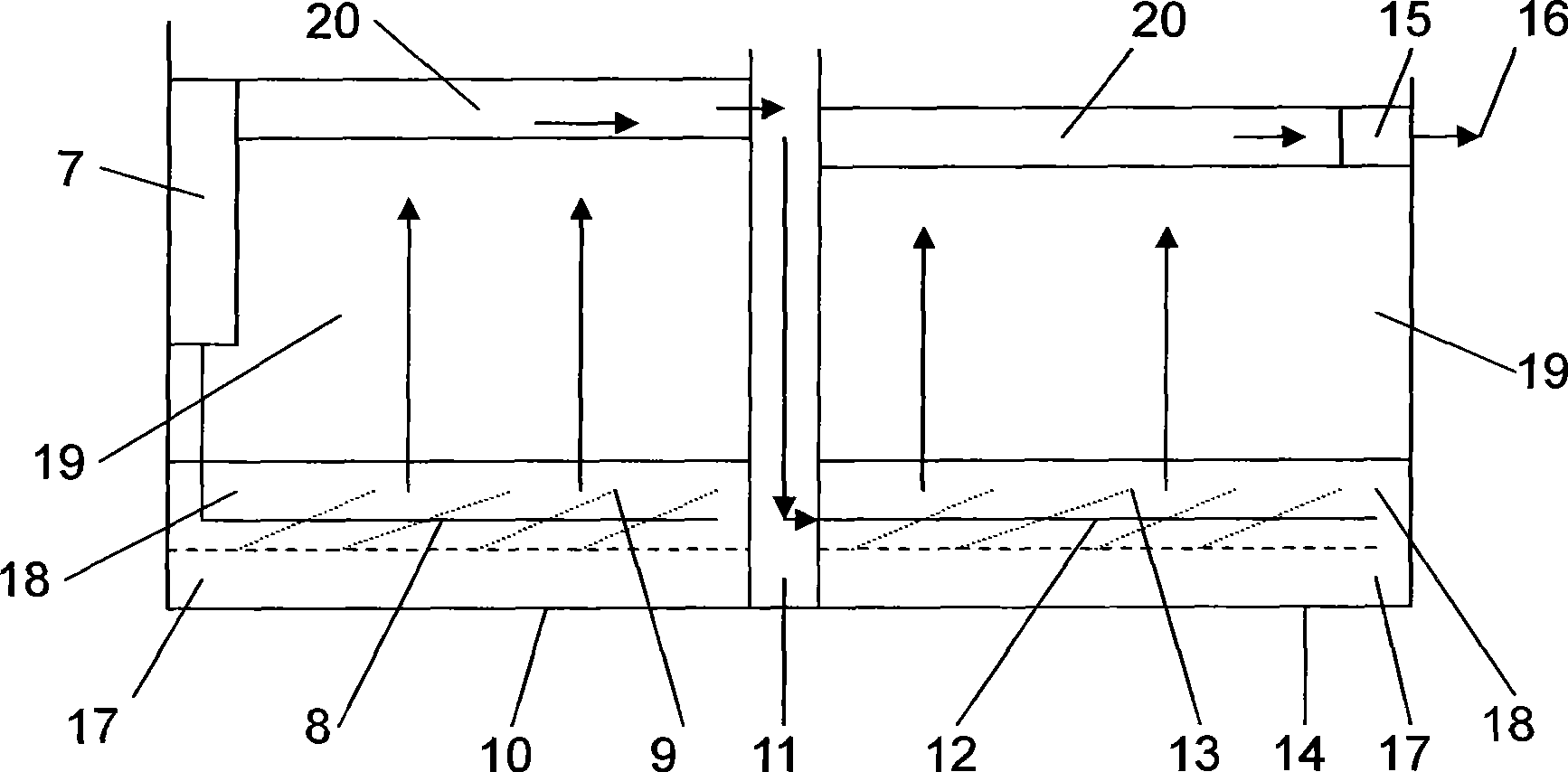

High-efficient circulating vertical flow constructed wetland and device suitable for sewage decentralized treatment

InactiveCN102642978AIncrease dissolved oxygen concentrationExtension of timeMultistage water/sewage treatmentConstructed wetlandMicroorganism

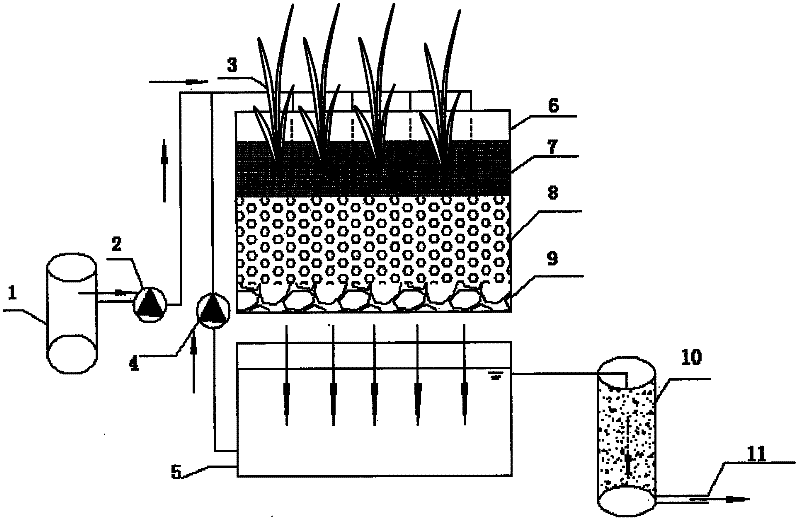

The invention belongs to the field of sewage ecological treatment, and the purpose is to provide a device and a method for sewage decentralized treatment in circulating vertical flow constructed wetlands. The invention comprises the following aspects: 1) the high-efficient circulating vertical flow constructed wetland system comprises three main components of a vertical flow constructed wetland, a circulating water tank, and a reinforced adsorption column; 2) the operation modes comprise an intermittent mode and a continuous mode. Fillers of the constructed wetland are proportional compositions of several fillers which are low in price and high in adsorption capacities for nitrogen and phosphorus; plants which have strong durability against pollution and have landscape value (thalia dealbata or day lily) or economic value (hybrid pennisetum) are planted on the wetland surface. The invention adopts the high-efficient filler composition to reinforce nitrogen and phosphorus adsorption; effluent backflow increases the dissolved oxygen inside the vertical flow constructed wetland, and enhances the nitration capability of microbes in the wetland; the denitrification capability is enhanced; the contact time of sewage and the fillers is increased; and the removal of phosphorus is enhanced. Series-parallel combinations can be selected flexibly with respect to different sewage types, and the applicability is strong.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

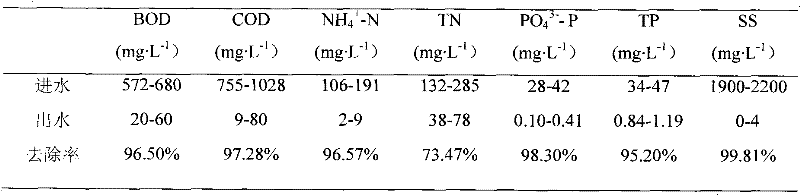

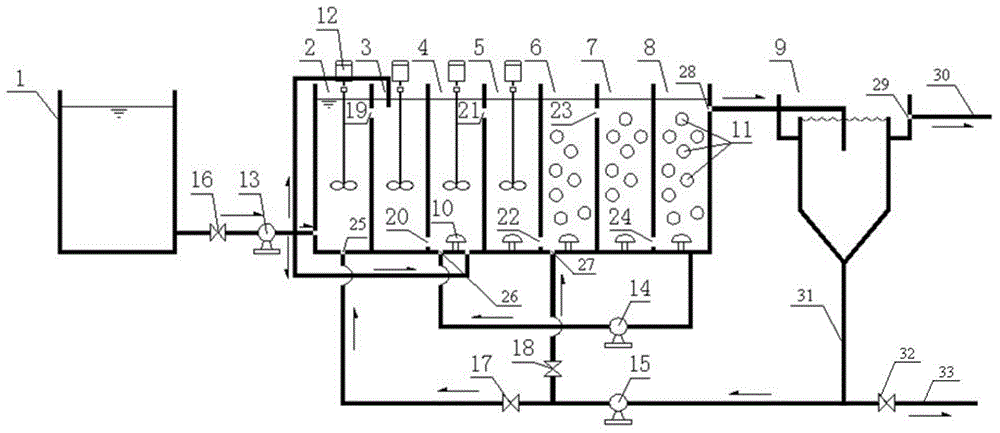

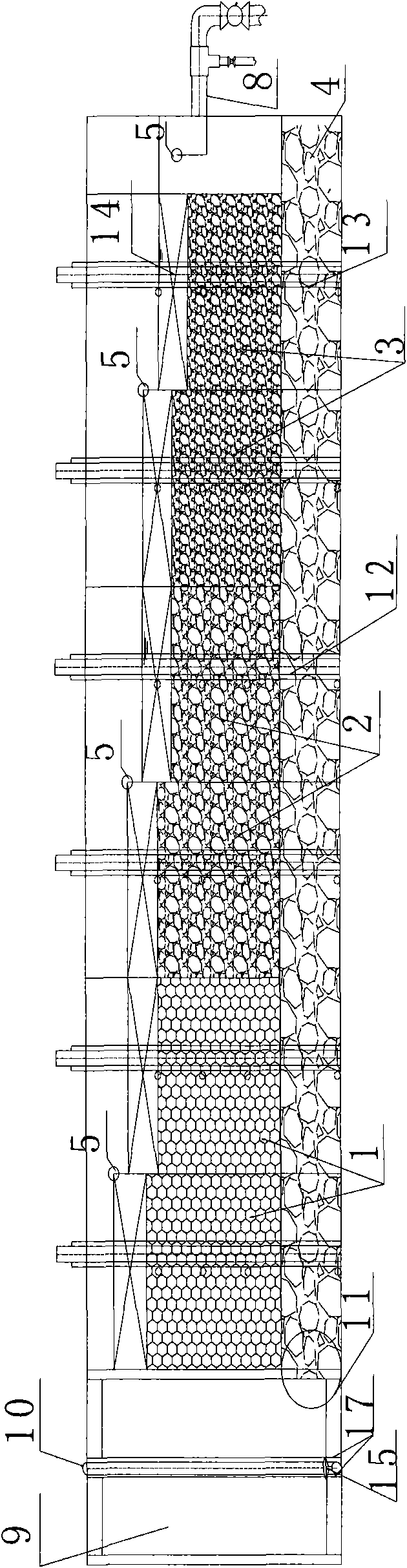

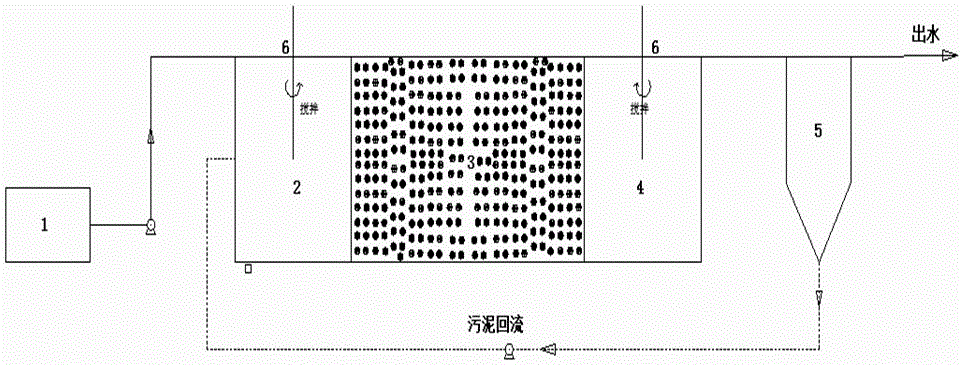

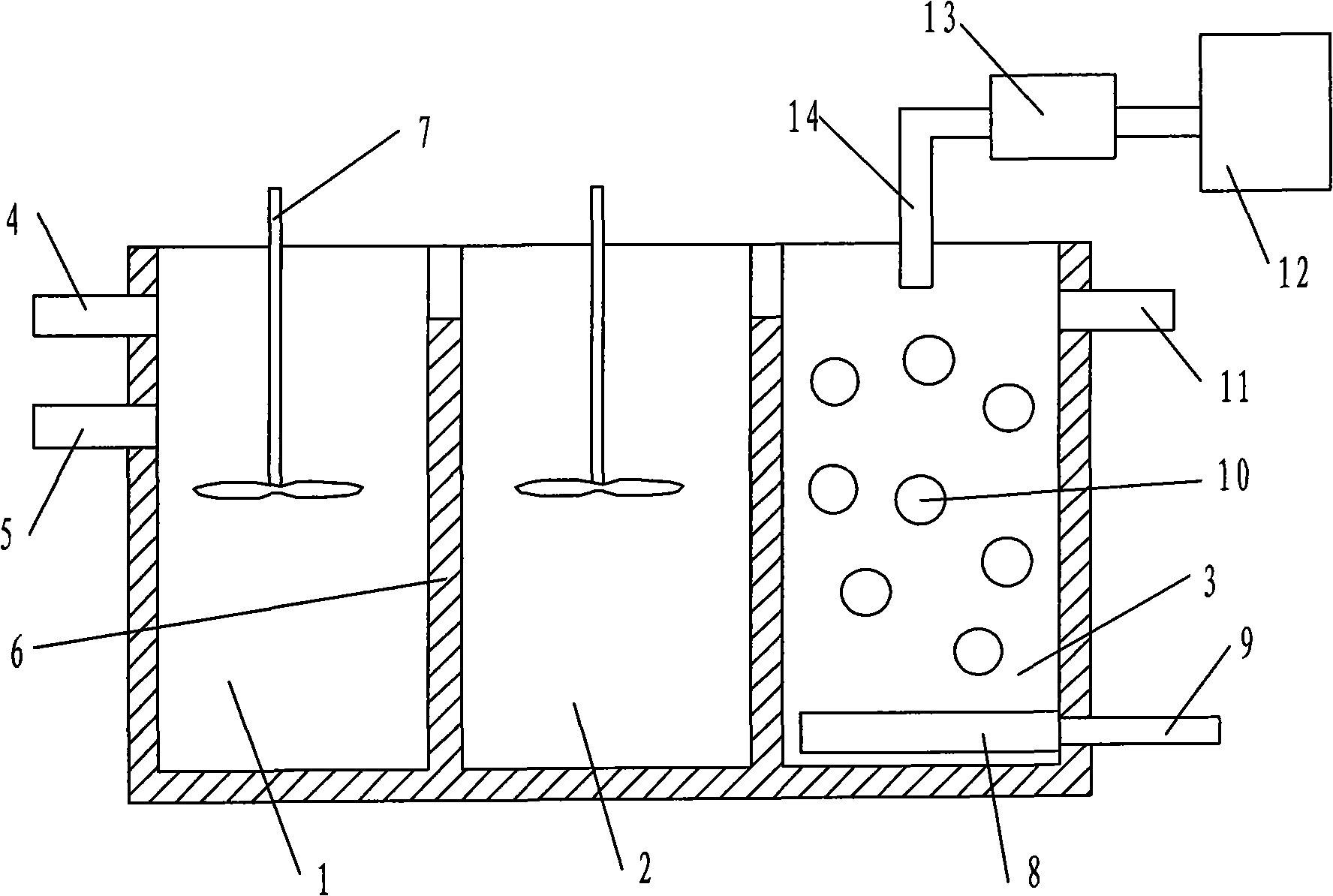

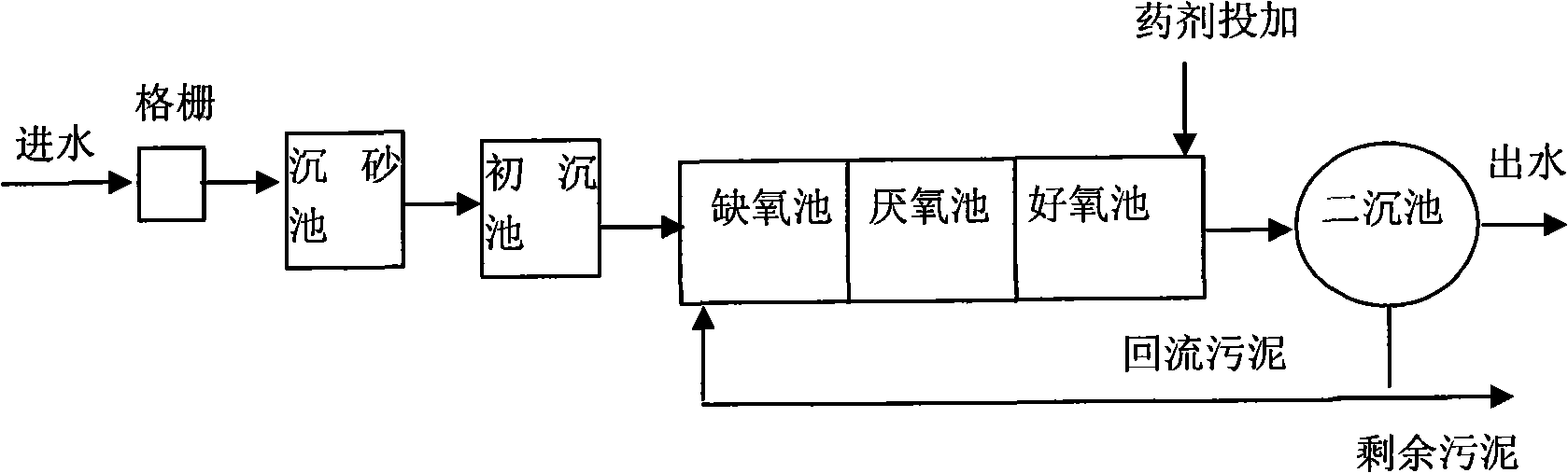

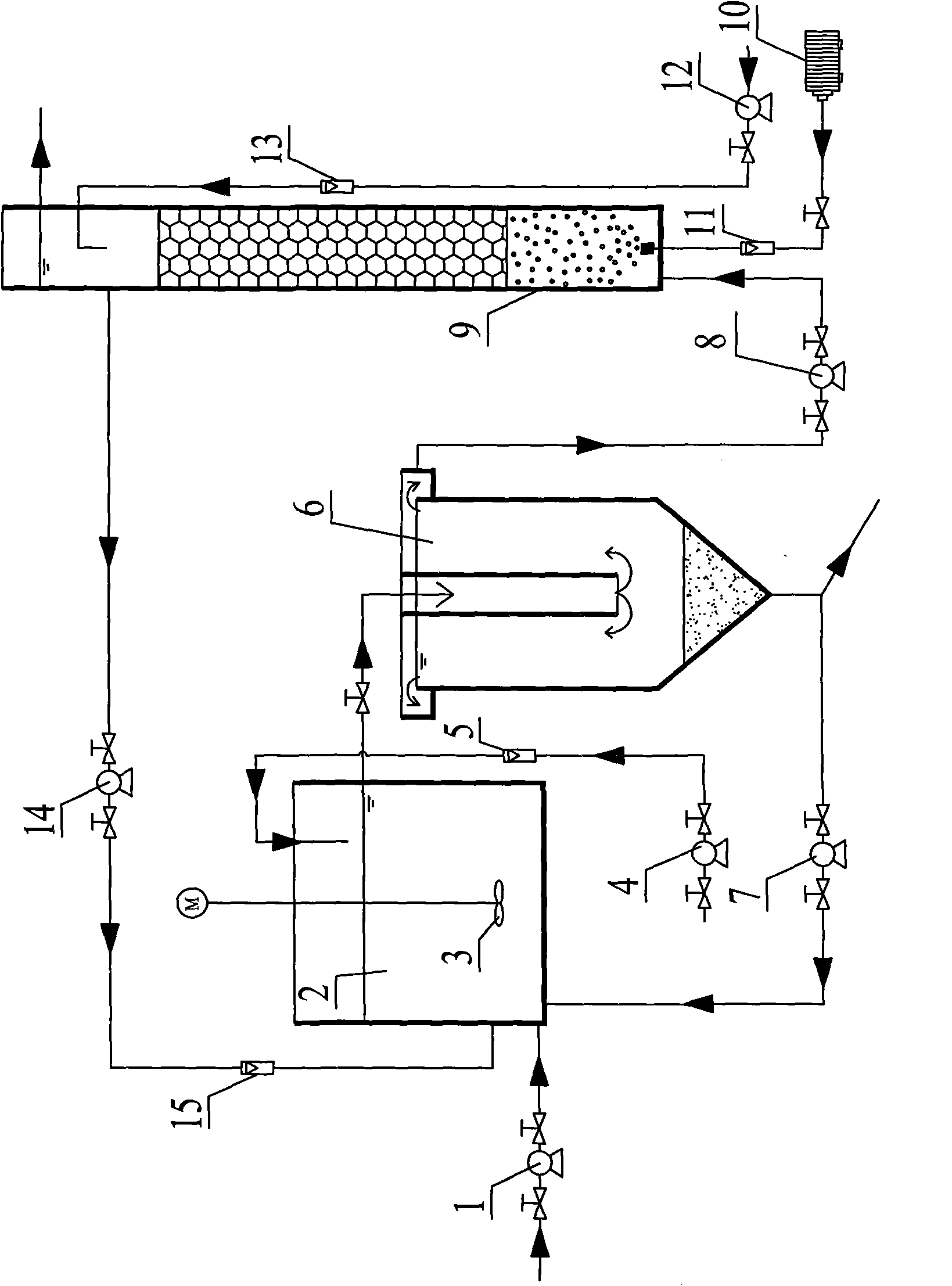

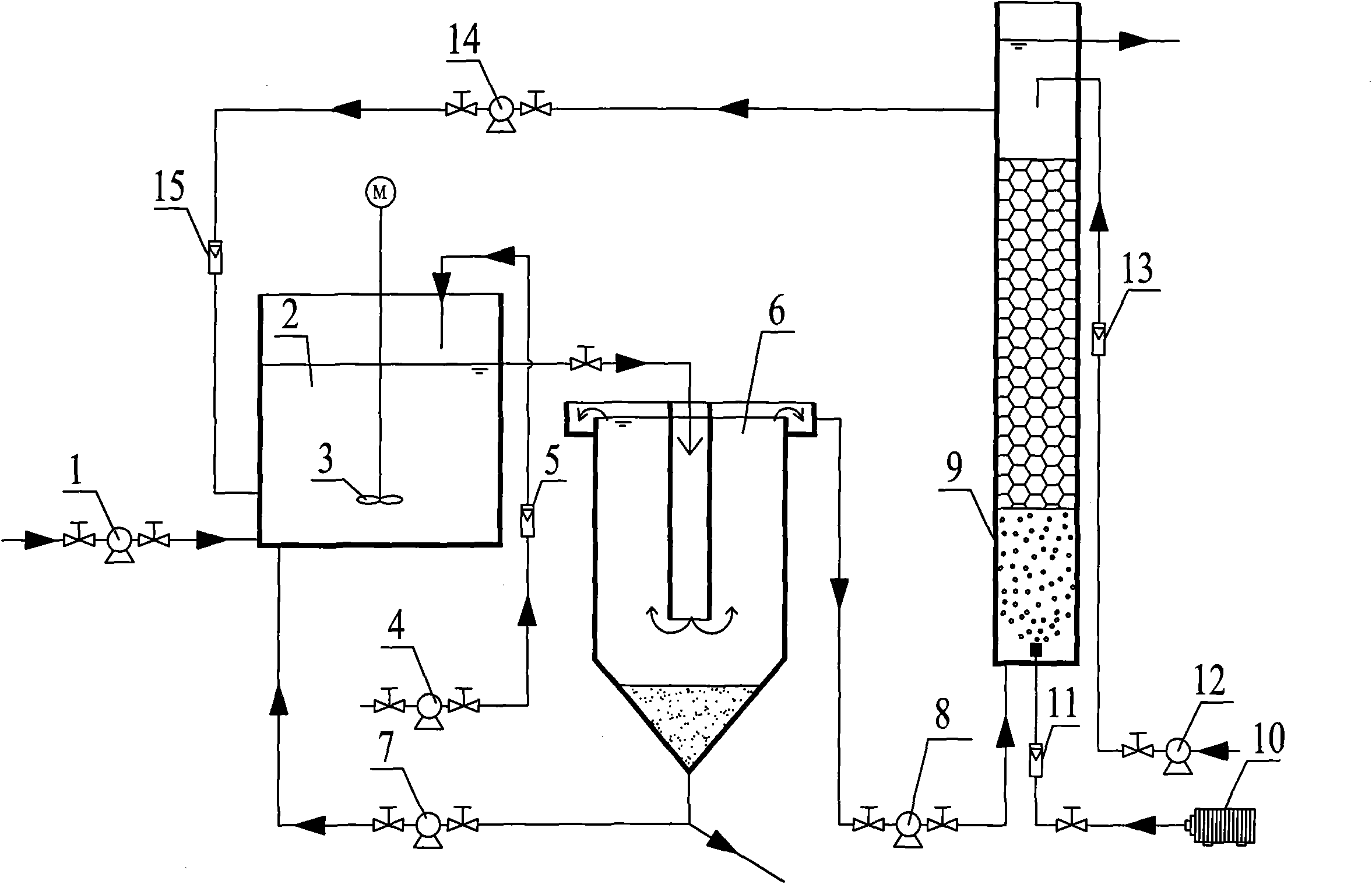

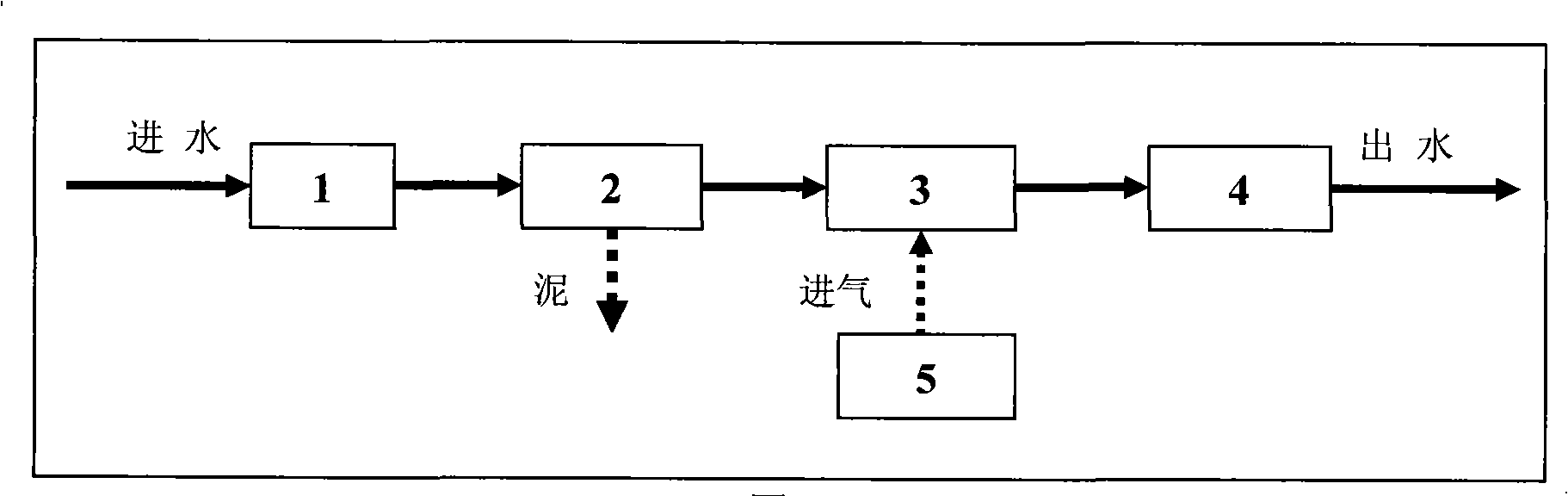

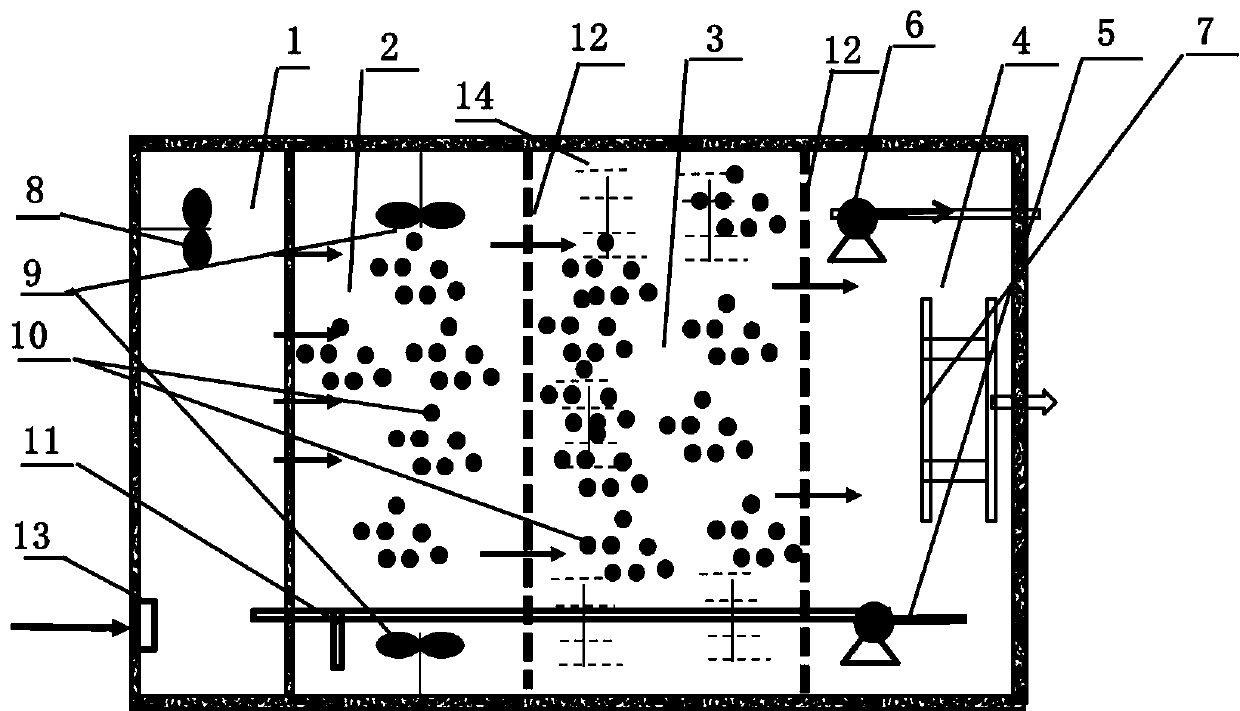

Biology processing apparatus capable of processing sewage at low-temperature with low carbon-nitrogen-ratio in cold region and method for processing sewage at low-temperature with low carbon-nitrogen-ratio in cold region

ActiveCN104150716AIncrease disturbanceEasy to updateMultistage water/sewage treatmentSludgeWater storage tank

The invention relates to a biology processing apparatus capable of processing sewage at low-temperature with low carbon-nitrogen-ratio in a cold region and a method for processing sewage at low-temperature with low carbon-nitrogen-ratio in the cold region, which relates to the biology processing apparatus for processing sewage and the method for processing sewage. According to the invention, problems that the ratio of carbon source and nitrogen source of sewage in winner at the cold region is low, the synchronization nitrogen and phosphorus removal efficiency in the current sewage processing technology is low, the index of nitrogen and phosphor in a processed effluent can not reach the standard can be solved. The apparatus comprises a water storage tank, a pre-conditioning hypoxia pool, an anaerobic pond, an anoxic pool, an aerobic tank, a sedimentation basin, an aeration head, a filling material, a stirrer, a water inlet pump, a reflux pump, a valve, an outlet pipe, a sludge discharge pipe and a residual sludge discharge pipe; The method comprises the following steps: 1)culturing microbe on a filling material; 2)adjusting operation parameter; 3)adjusting reflux ratio parameter; 4)passing the sewage through the pre-conditioning hypoxia pool, the anaerobic pond, the anoxic pool, the aerobic tank and the sedimentation basin for processing to obtain the processed water. The apparatus and the method can be used for construction and reconstruction of the sewage processing technology at low-temperature with low carbon-nitrogen-ratio in a north region.

Owner:HARBIN INST OF TECH

Immobilized nitrobacteria enrichment culture method and device in sewage treatment process

ActiveCN104962505AReduce the probability of accumulationPromote enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeBiofilm

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Method for degrading ammonia nitrogen in high-salinity sewage by microbes

InactiveCN103232145ASolve the problem of ammonia nitrogen degradationShort reaction timeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandSludge

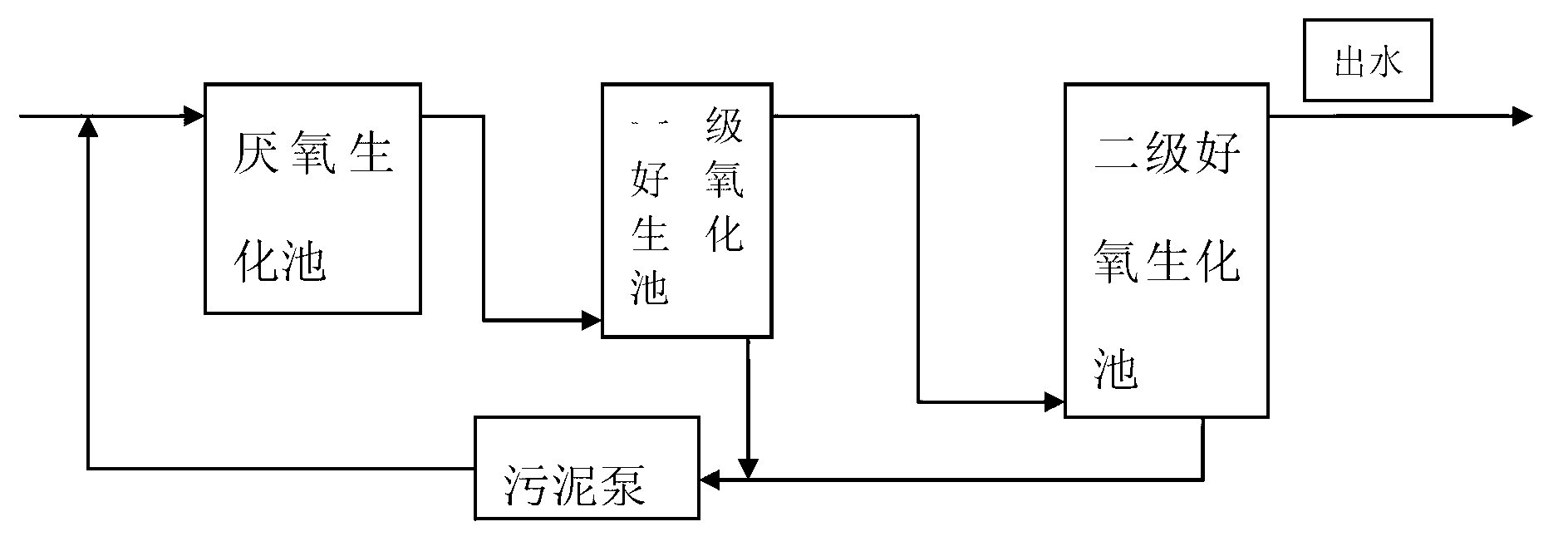

The invention discloses a method for degrading ammonia nitrogen in high-salinity sewage by microbes, wherein a treatment system in the method comprises an anaerobic biochemical reaction tank, a first-stage aerobic biochemical pool and a second-stage aerobic biochemical pool. Firstly, the sewage and the recirculation water simultaneously flow into the anaerobic biochemical reaction tank to be treated by denitrification and hydrolysis reaction; then, the sewage orderly flows into the first-stage aerobic biochemical pool and the second-stage aerobic biochemical pool to be respectively treated by first-stage aerobic treatment and the second stage aerobic treatment; the active sludge in the first-stage aerobic biochemical pool is the domesticated salt-tolerant bacteria for performing first-stage nitration on the ammonia nitrogen, and besides the domesticated salt-tolerant bacteria, efficient nitrifying bacteria are also added into the second-stage aerobic biochemical pool for performing second-stage high-strength nitration on the ammonia nitrogen=, thus, the effluent ammonia nitrogen and the COD (Chemical Oxygen Demand) can reach the emission standard.

Owner:CHINA NAT OFFSHORE OIL CORP +1

New high-nitrogen organic sewage treatment biochemical denitrification process

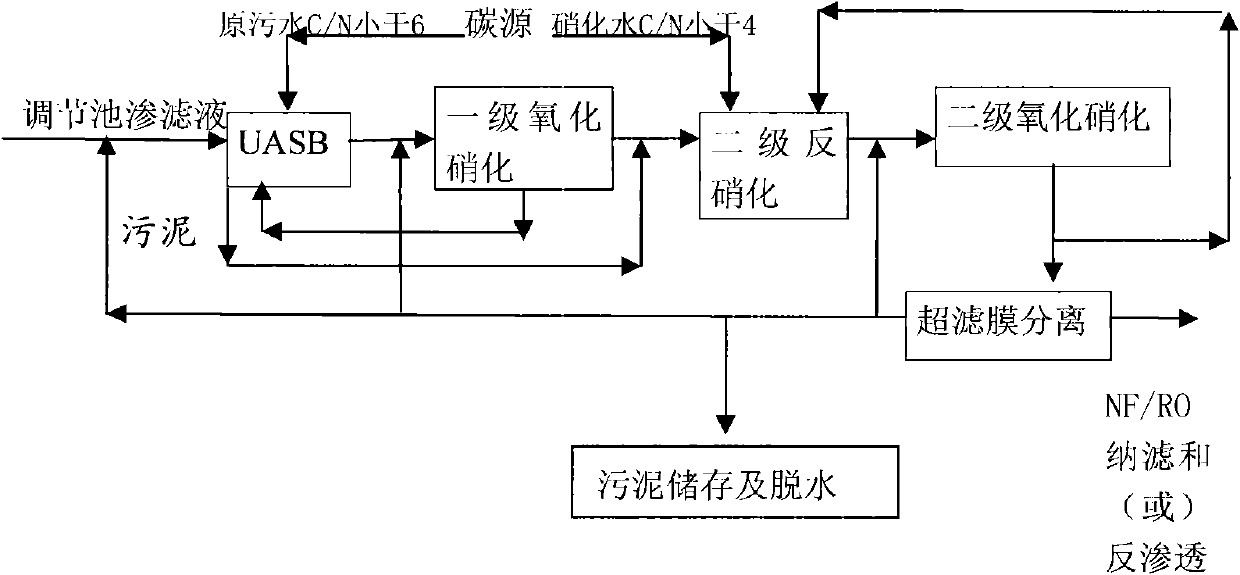

ActiveCN102001786ASolve the problem of no refluxReduce denitrificationMultistage water/sewage treatmentFiltration membraneNitration

The invention relates to a new high-nitrogen organic sewage treatment biochemical denitrification process. The process mainly comprises the following technical steps of: 1, feeding raw sewage which accords with conditions into an upflow anaerobic sludge blanket (UASB); and simultaneously feeding reflow mixed solution of a subsequent oxidation nitration tank (O1) and a part of thick solution of a membrane bioreactor (MBR) ultra-filtration membrane separation device into the UASB; 2, simultaneously feeding effluent of the UASB, a part of thick solution of the MBR ultra-filtration membrane separation device and air into the oxidation nitration tank (O1); 3, feeding the effluent of the O1 tank into a denitrification tank (a tank A) of anoxic zone / aerobic zone A / O(2), simultaneously feeding the remaining sludge of the UASB and replenishing carbon, forming an anoxic condition at the tank A to perform denitrification, replenishing the part of thick solution of the MBR ultra-filtration membrane separation device and supplying air (oxygen) into the O(2) tank to further perform oxidation nitration reaction respectively, and removing chemical oxygen demand (COD), biochemical oxygen demand after 5 days (BOD5), total nitrogen (TN) and NH3-N; and 4, feeding the effluent of the A / O (2) into the MBR ultra-filtration membrane separation device, intercepting the active sludge and macromolecularCOD and enriching in the thick solution; feeding the thick solution into the UASB, the O1 tank and the A / O (2) tank respectively; performing sludge dehydration treatment on the remaining thick solution; and removing the COD and the BOD5. The total nitrogen removal rate of the technology is improved by over 50 percent.

Owner:CHINA NERIN ENG

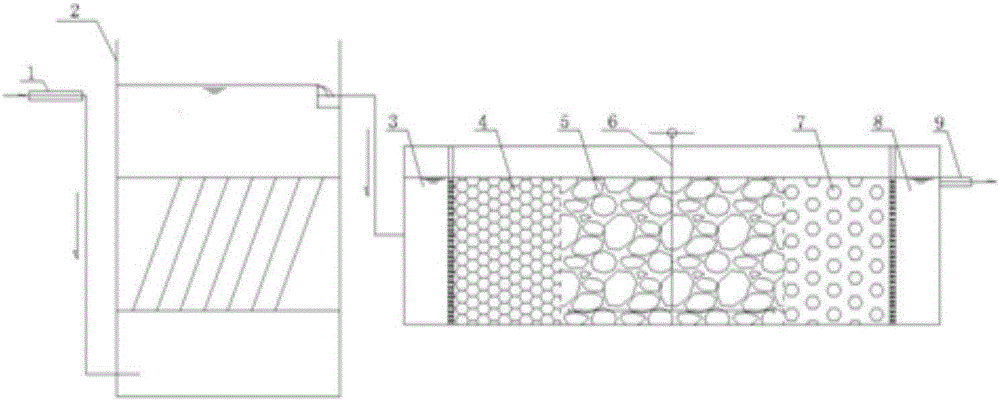

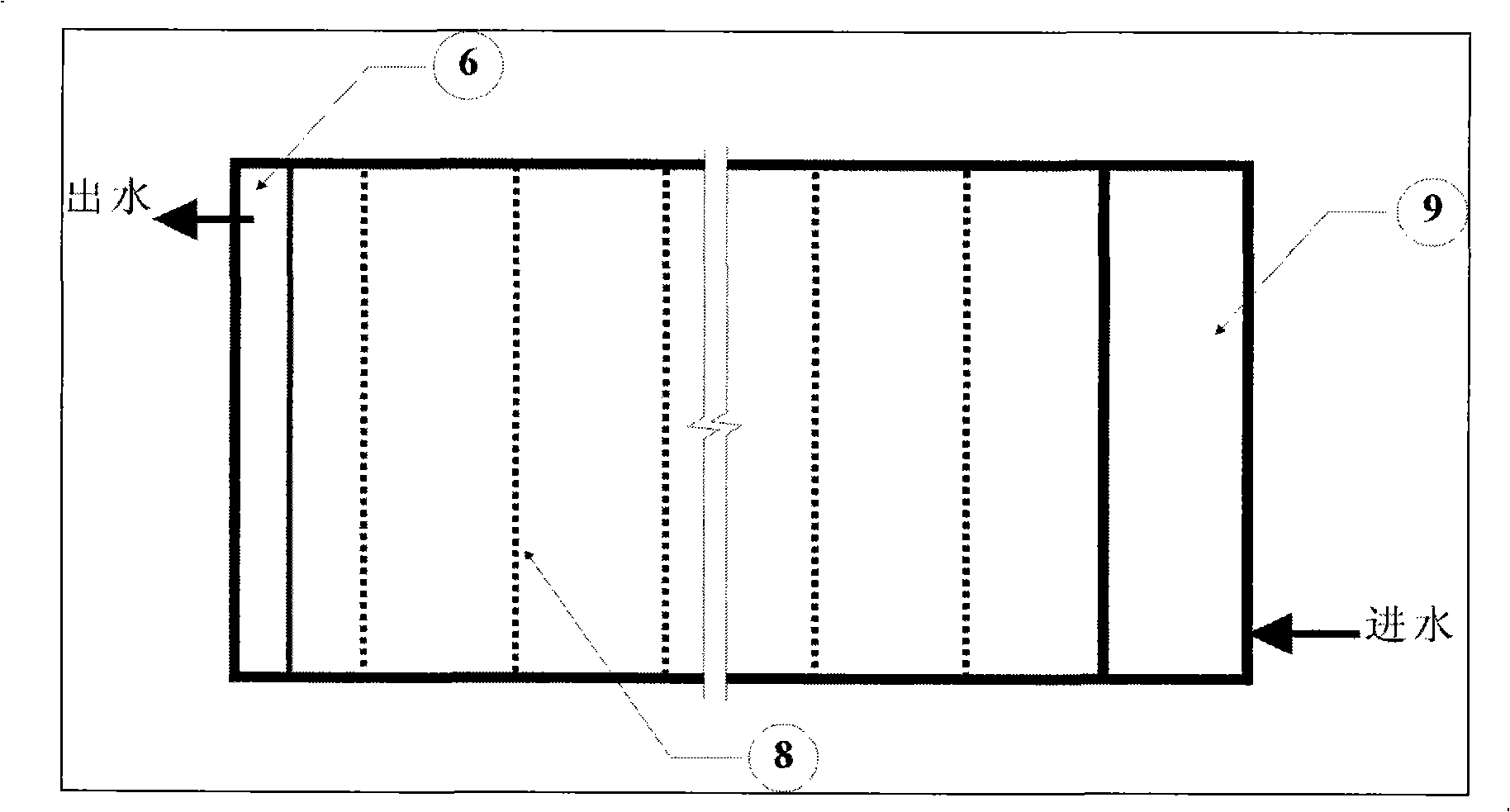

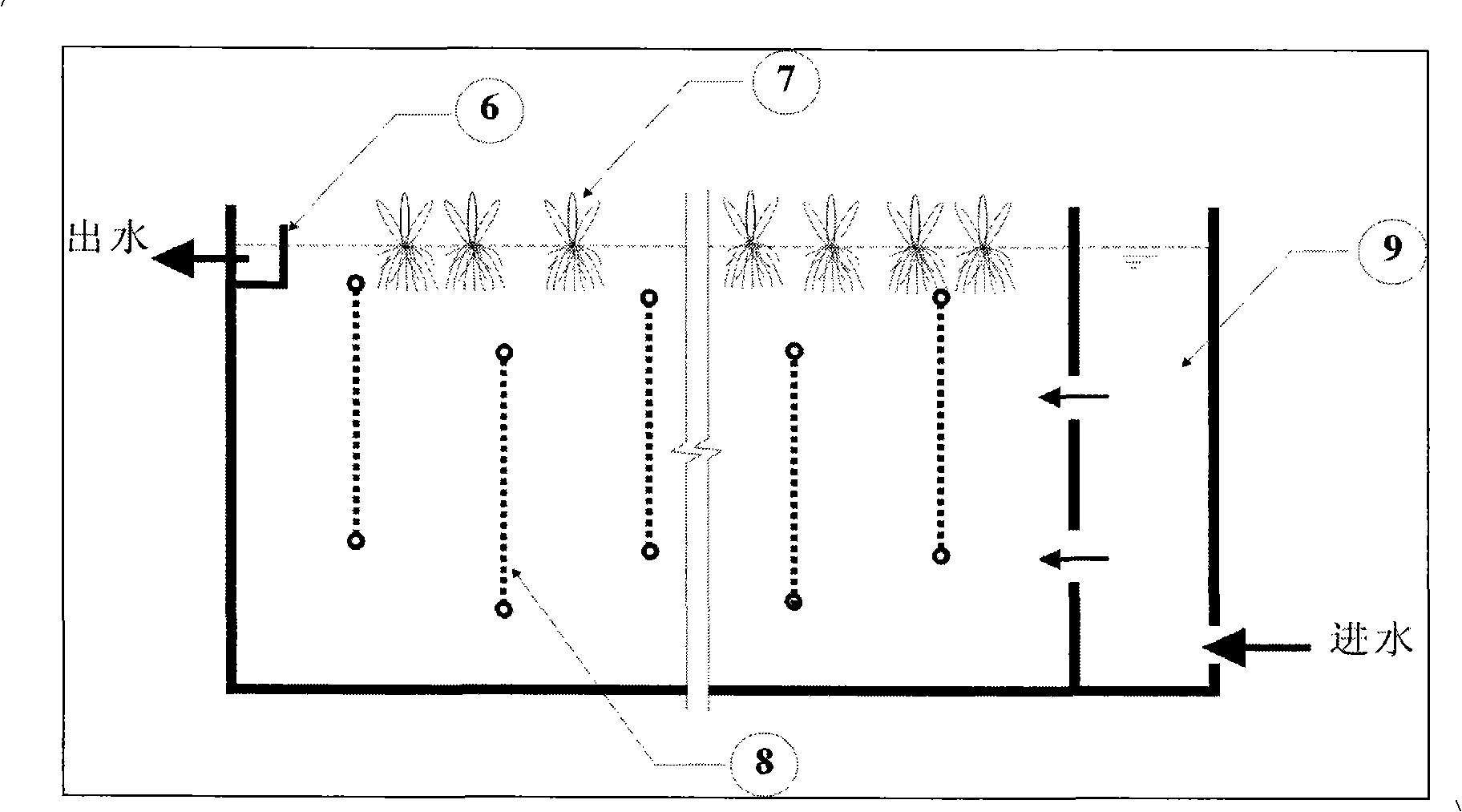

Filtration-fabric anti-clogging strengthening compound flow constructed wetland domestic sewage treatment system

InactiveCN101638288AReduce physical blockageReduce demandMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandFiltration

The invention relates to a filtration-fabric anti-clogging strengthening compound flow constructed wetland domestic sewage treatment system comprising a pretreatment region, a main reaction region andan exhalant region, wherein the pretreatment region comprises a framed tube, an intake pipe, a filter bag, an air inlet pipe and a porous aerator; the main reaction region is formed by connecting a first unit, a second unit and a third unit in series; the bottom of the main reaction region is provided with a gravel water-distribution layer; a biological porcelain granule layer is distributed in the first unit; gravel and a steel slag layer are distributed in the second unit; a zeolite layer is distributed in the third unit; each unit is divided into a left grid and a right grid; the left gridis higher than the right grid; the top of an aquatic plant root region in the left grid is provided with a triangular weir; the pretreatment region and the main reaction region are connected by a perforated water-distribution plate which is arranged at one end of a gravel water-distribution layer; and the exhalant region comprises an exhalent pipe which is arranged at one side of the main reaction region. The invention has the advantages of high pollutant removal rate, stable system operation, greatly improved hydraulic load, small floor area, low operation and maintenance costs, and the like.

Owner:TONGJI UNIV

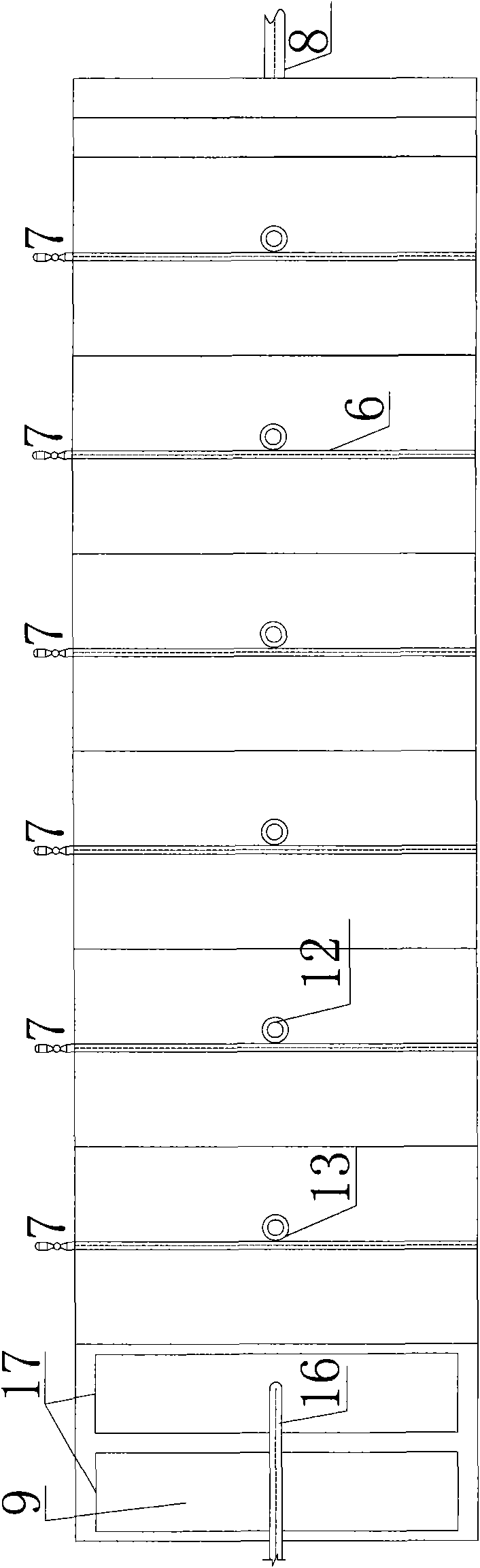

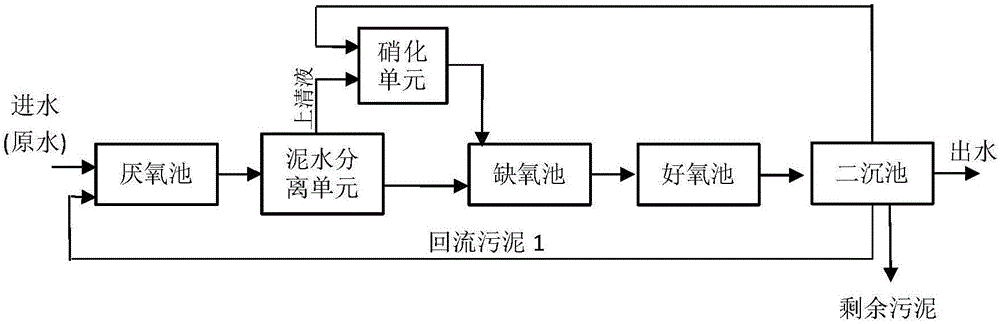

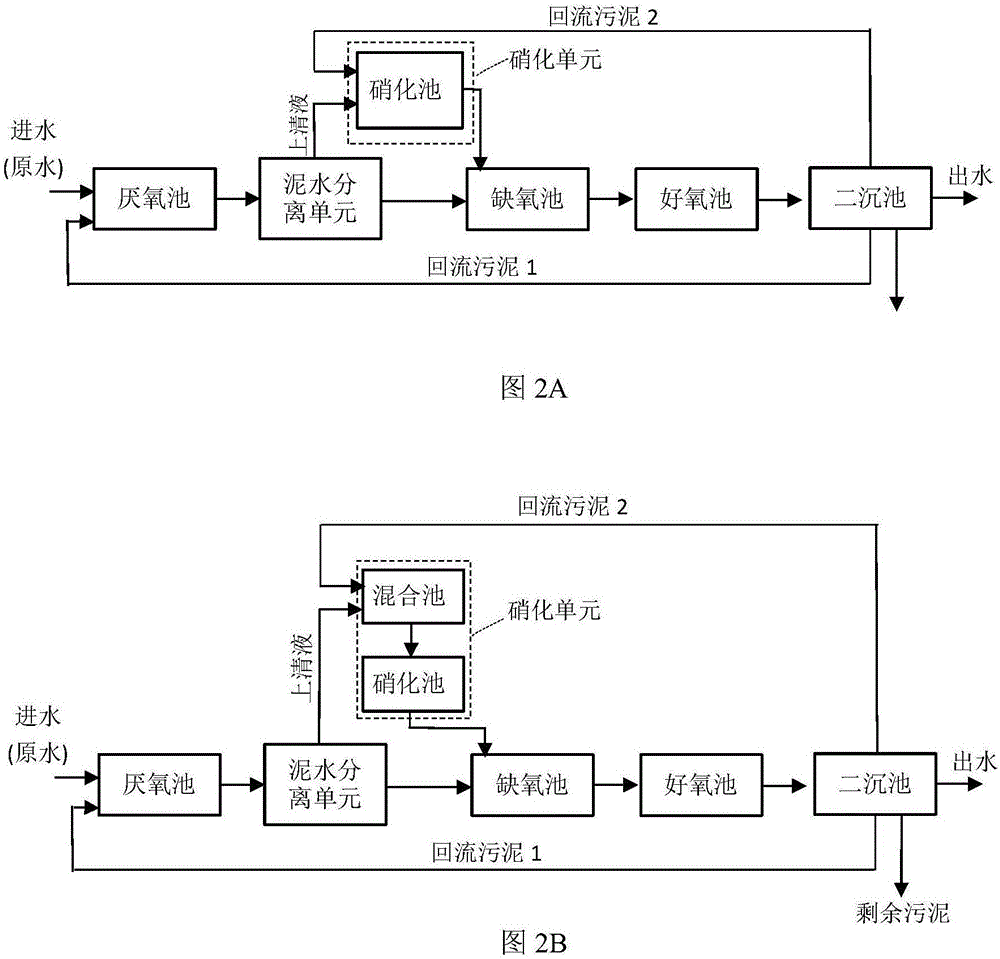

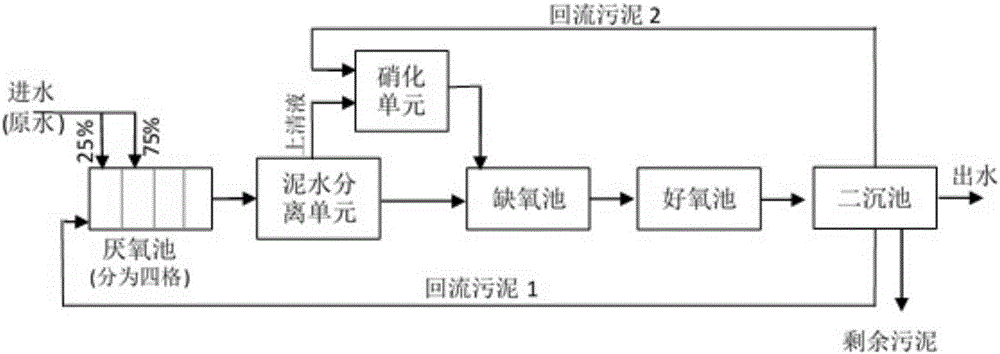

Sewage denitrification and phosphorous removal system

ActiveCN106745743ASolve problemsOvercoming the Insufficient Capability of Nitrogen and Phosphorus RemovalTreatment with aerobic and anaerobic processesSludgeWastewater

The invention provides a sewage denitrification and phosphorous removal system. The sewage denitrification and phosphorous removal system comprises an anaerobic tank, a mud-water separation unit, a nitrification unit, an oxygen-poor tank, an aerobic tank and a secondary sedimentation tank, wherein raw water and reflowing sludge 1 of the secondary sedimentation tank enter the anaerobic tank; a mixed solution of the anaerobic tank enters the mud-water separation unit; supernatant of the mud-water separation unit and reflowing sludge 2 of the secondary sedimentation tank enter the nitrification unit; a mixed solution of the nitrification unit and sludge of the mud-water separation unit enter the oxygen-poor tank; a mixed solution in the oxygen-poor tank sequentially enters the aerobic tank and the secondary sedimentation tank. The sewage denitrification and phosphorous removal system provided by the invention can realize deep denitrification and phosphorous removal of municipal wastewater treatment and is applicable to newly built sewage plants, and modification of built sewage treatment plants is easy to realize.

Owner:深圳市万木水务有限公司

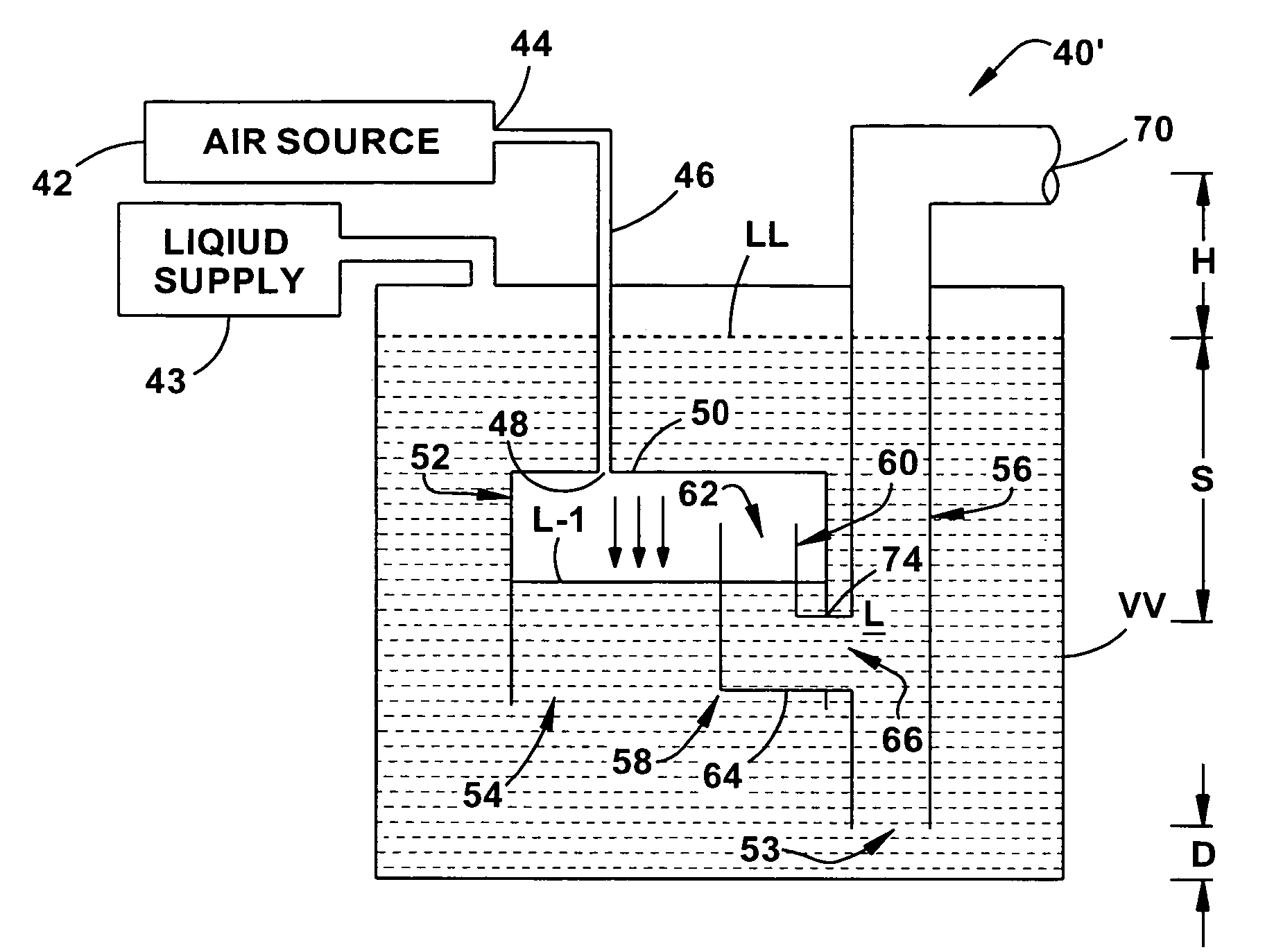

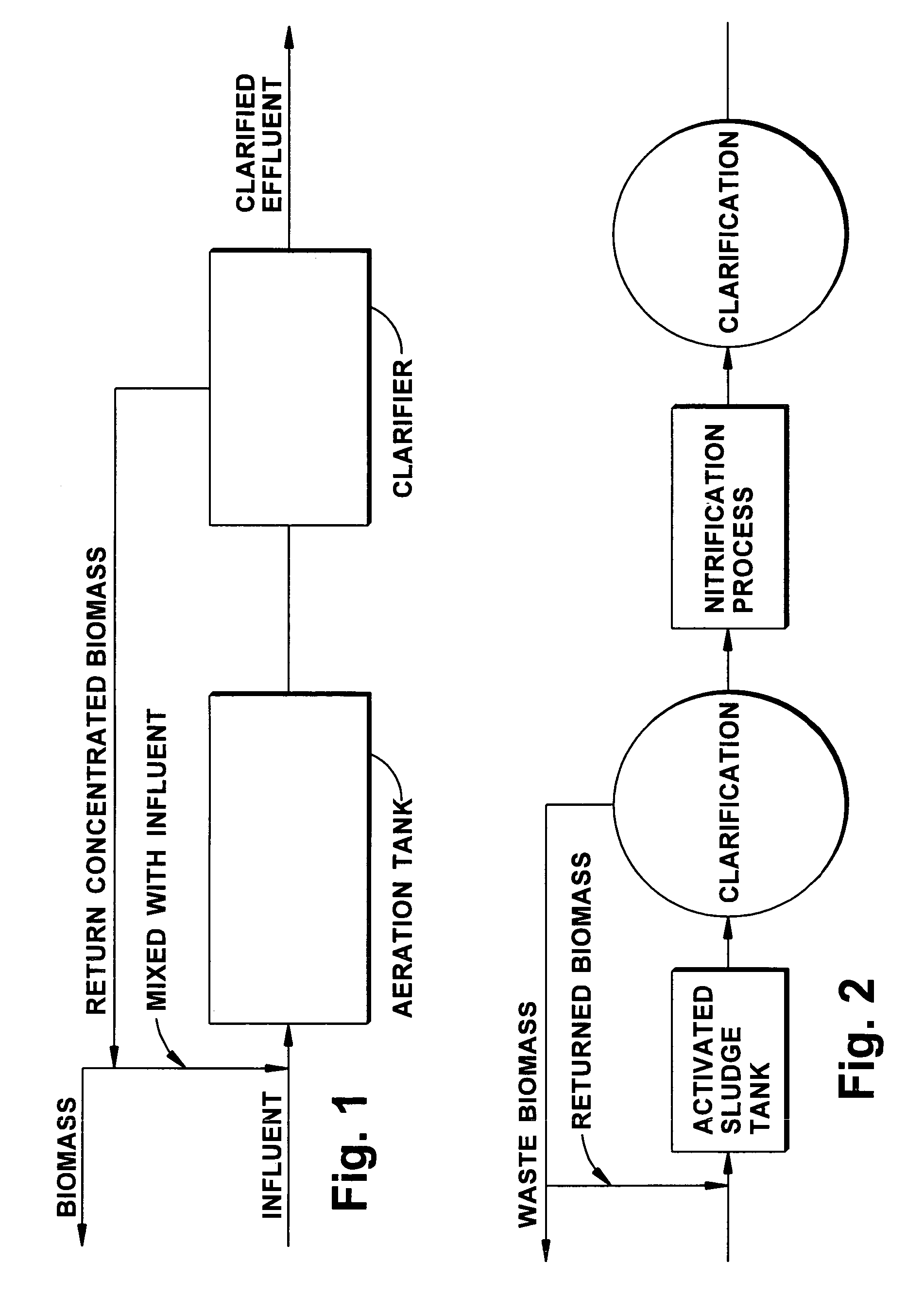

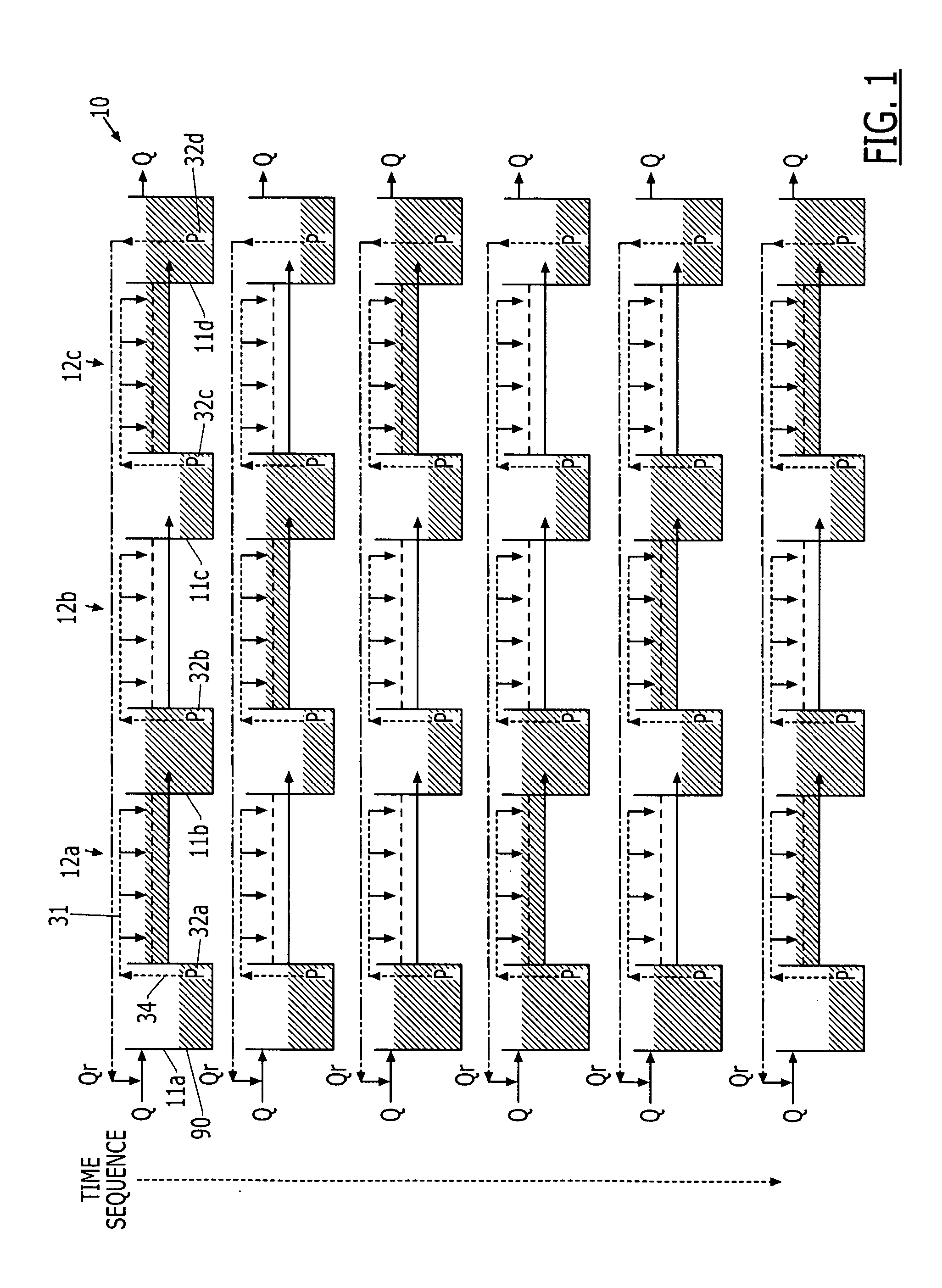

Nitrification system and method

InactiveUS7294255B2Ammonia reductionIncrease resistanceMixing methodsWater contaminantsActivated sludgeNitrifying bacteria

A system reduces ammonia within a fluid flow. The system includes an aeration vessel, a clarifier vessel, and a geyser pump. The aeration vessel nitrifies bacteria within the fluid flow. The aeration vessel has an intake flow rate. The clarifier vessel receives fluid from the aeration vessel. The geyser pump transfers activated sludge from the clarifier vessel to the aeration vessel. The geyser pump transfers activated sludge at a specific flow rate. The specific flow rate is less than 150% of the intake flow rate.

Owner:GEYSER PUMP TECH

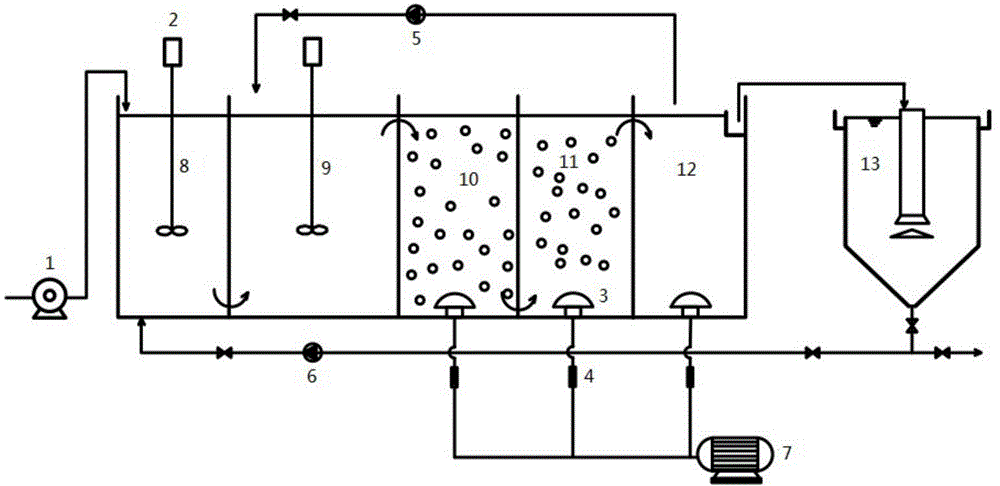

Process method of MBBR (Moving Bed Biofilm Reactor) for treating urban sewage

InactiveCN105129989ASolve the dispute of different mud agesGood for denitrification and phosphorus removalTreatment with aerobic and anaerobic processesMunicipal sewageMoving bed biofilm reactor

The invention discloses a process method of an MBBR (Moving Bed Biofilm Reactor) for treating urban sewage. The process method comprises the steps that suspended matters and part of organic matters in the urban sewage which is subjected to primary treatment are removed, then the urban sewage enters into an anaerobic zone, an aerobic zone and an anoxic zone of the MBBR in sequence by an intake sump, and enters into a secondary sedimentation tank through the anoxic zone; carriers are suspended in the anaerobic zone of the MBBR, and the surfaces of the carriers are attached with nitrobacteria, which is conductive to growth of the nitrobacteria with long sludge age, the organic matters can be subjected to degradation treatment by activated sludge in all zones, and phosphorus in the sewage is processed by the activated sludge, so as to realize simultaneous nitrogen and phosphorus removal. The process method disclosed by the invention has the characteristics that the effect of nitrogen and phosphorus removal is good and the utilization rate of organic matters is high, meanwhile, the sludge production is low, the nitrification liquid reflux does not exist, the operation cost is reduced, and the process method is particularly suitable for treating domestic sewage with low ratio of C / N.

Owner:TONGJI UNIV

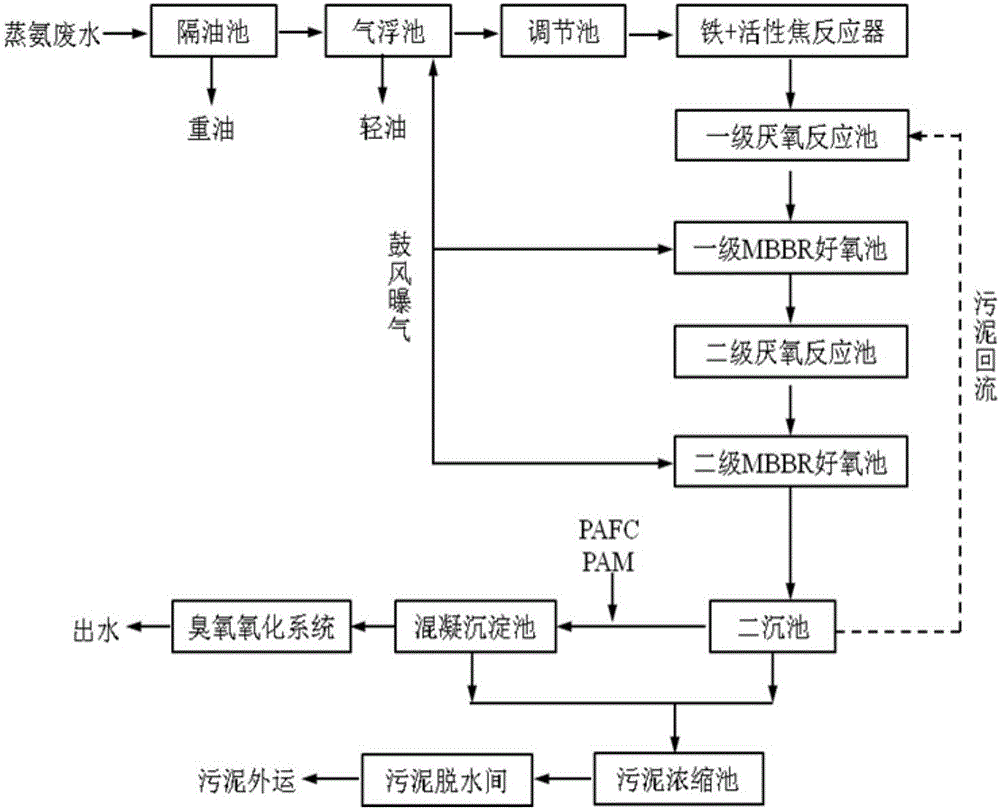

Technological method for treating coking wastewater

ActiveCN106396258AImprove biodegradabilityAchieve recyclingMultistage water/sewage treatmentSuspended particlesElectrolysis

The invention discloses a technological method for treating coking wastewater. The technological method comprises the following steps that (1) coking wastewater is subjected to ammonia distillation and oil-water separation sequentially; (2) coking wastewater after oil-water separation is subjected to water quality regulation; (3) coking wastewater after water quality regulation enters an iron+activated coke reactor for iron-carbon micro-electrolysis and suspended particles in the coking wastewater are absorbed; (4) coking wastewater flowing out of the iron+activated coke reactor is subjected to biological removal of nitrogen and organic pollutant removal treatment; (5) coking wastewater after biochemical treatment is subjected to coagulating sedimentation for mud-water separation; (6) mud after mud-water separation is subjected to thickening and dehydration treatment, and the coking wastewater after mud-water separation is subjected to deep ozonation treatment; the technology operates stably, the cost is low, the treatment efficiency is high, the load capacity resistance is high, and the operation is easy.

Owner:HUATIAN ENG & TECH CORP MCC +1

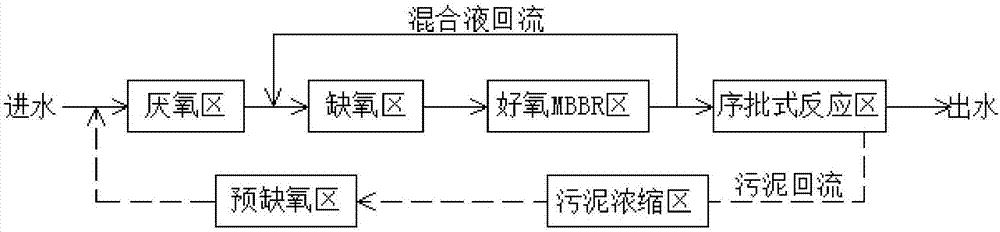

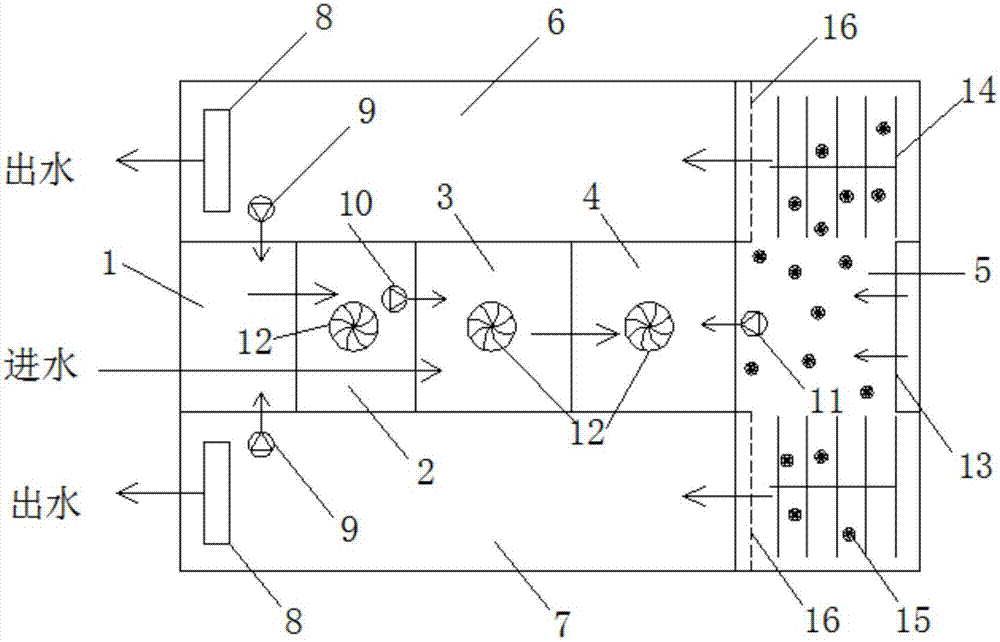

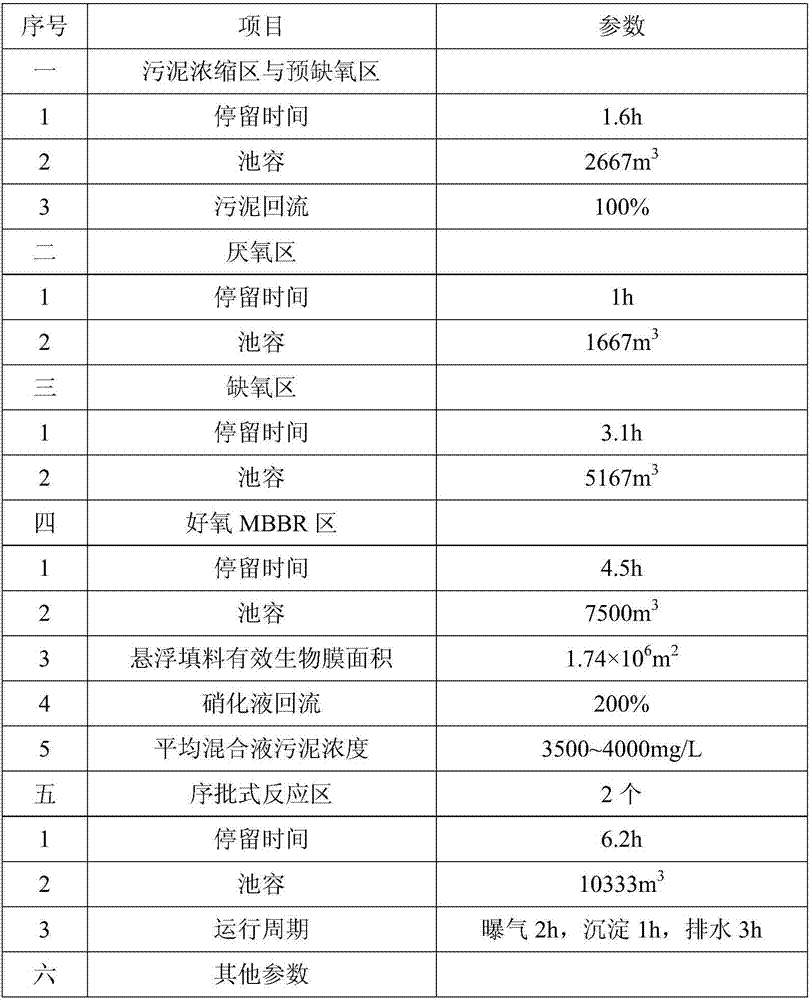

MSBR (Modified SBR) nitrogen and phosphorus removal technique based on MBBR (Moving Bed Biofilm Reactor)

InactiveCN107285463AHigh volume loadImprove adjustabilityWater contaminantsTreatment with aerobic and anaerobic processesHypoxic preconditioningMoving bed biofilm reactor

The invention discloses an MSBR (Modified SBR) nitrogen and phosphorus removal technique based on an MBBR, and belongs to the technical field of sewage treatment. The technique is based on a system consisting of seven units, including a sludge concentration area, a hypoxic preconditioning area, an anaerobic area, an anoxic zone, an aerobic MBBR area, a sequencing batch reaction I area and a sequencing batch reaction II area, wherein suspended packing is all dropped into the aerobic MBBR area, a medium hole perforating aeration system is arranged at the bottom of the aerobic MBBR area, a water distribution system is arranged at a water inlet, and an interception screening system is arranged at a water outlet. According to the MSBR nitrogen and phosphorus removal technique based on the MBBR disclosed by the invention, the advantages of an MSBR technique and the MBBR technique are combined, the technique has the advantages of high volume load and stable effluent effect, and is suitable for carrying out update or capacity increasing transformation on the original MSBR technique, so that the treatment capability of the existing technique is promoted, and meanwhile, the technique is applied to new construction items, so that the occupied area can be greatly reduced.

Owner:QINGDAO SPRING WATER TREATMENT

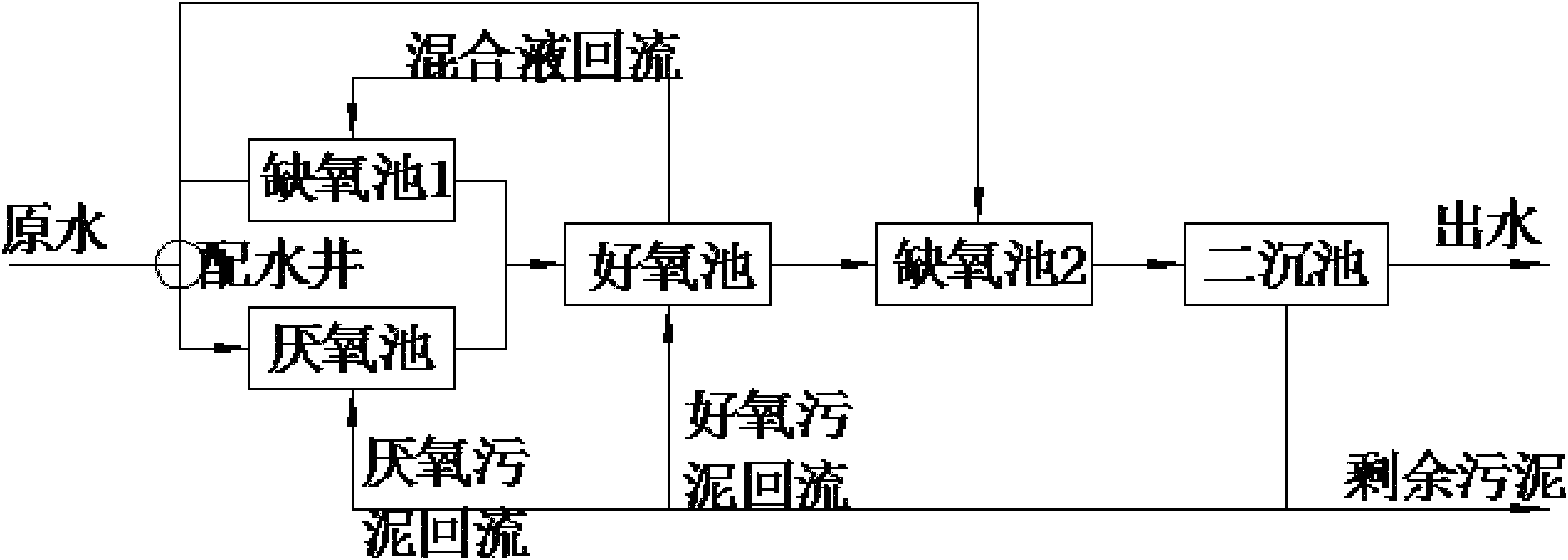

Low carbon source urban sewage strengthening denitrogenation dephosphorization technique and device

InactiveCN101264998AIncrease microbial biomassWill not cause churnWater/sewage treatmentTreatment with aerobic and anaerobic processesSludgeNitrogen

The invention provides an enhanced low-carbon source urban sewage denitrogenation and phosphorous removal process, and a biological-chemical combined sewage treatment device for realizing the process. The enhanced denitrogenation and phosphorous removal process comprises the steps of adding suspended filler in a biochemical reaction tank to increase microbial biomass, and at the same time adding phosphorous removal chemical agent at the end of the biochemical reaction tank. The biological-chemical combined sewage treatment device comprises a biochemical reaction tank and a chemical agent adding device, wherein the biochemical reaction tank is partitioned into an anoxic tank, an anaerobic tank and an aerobic tank that are connected in series; the anoxic tank and the anaerobic tank are respectively provided with a stirring paddle , and a water inlet pipe and a sludge return pipe are arranged at the side face of the anoxic tank; the aerobic tank is filled with 25-35% (v / v) suspended filler of the volume of the aerobic tank, an aeration pipe connected with an air inlet pipe is arranged at the bottom of the aerobic tank, and a water outlet pipe is arranged in the upper part of the aerobic tank; and the chemical agent adding device comprises a chemical agent tank, a metering pump and a chemical agent adding pipe that are sequentially connected, and the chemical agent adding pipe is connected with the aerobic tank.

Owner:SHANDONG JIANZHU UNIV

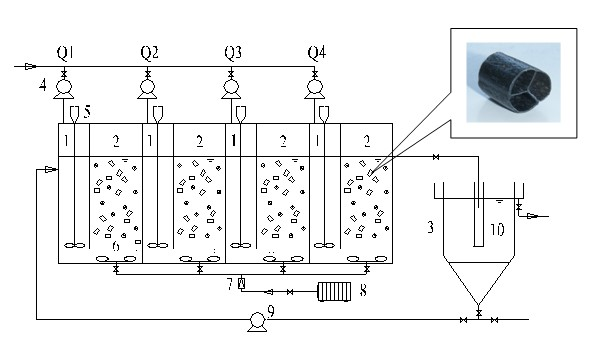

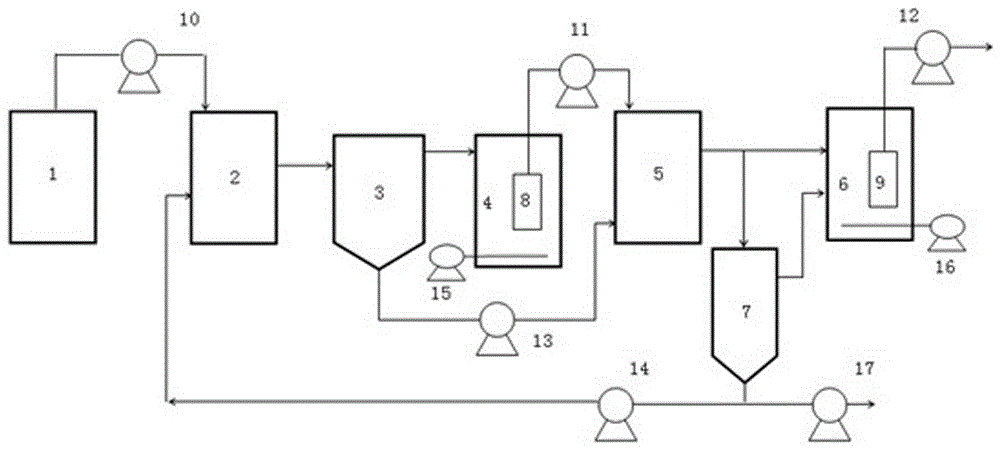

Four-stage three-phase fluidized bed step-feed deep nitrogen removal system

InactiveCN102358676ANot easy to loseSmall volumeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeNitrogen removal

The invention belongs to the field of domestic sewage purification, and relates to a method for treating domestic sewage by adopting a four-stage three-phase step-feed deep nitrogen removal system. The method solves the problems that the conventional domestic sewage treatment process is poor in nitrogen removal effect and difficult to reach the specified standards, and can fulfill the upgraded reforming goal of the conventional sewage plant on the premise that the civil facilities are not changed. The method comprises the step of respectively delivering the domestic sewage to a reactor from anoxic zones of four stages, wherein the anoxic zones and aerobic zones are arranged at intervals, so that nitration liquid reflux facilities of the system are saved; and sludge reflux is only performed in the first anoxic zone, so that the energy is saved and nitration liquid required by denitrification can be supplied to the first anoxic zone. A fluidized filling material is added into the aerobic zones, and a fluidized bed is organically combined with a step-feed process, so that the advantages of increasing the biomass and the bioactivity of the system, reducing sludge, enhancing the three-phase system in the system and the like are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

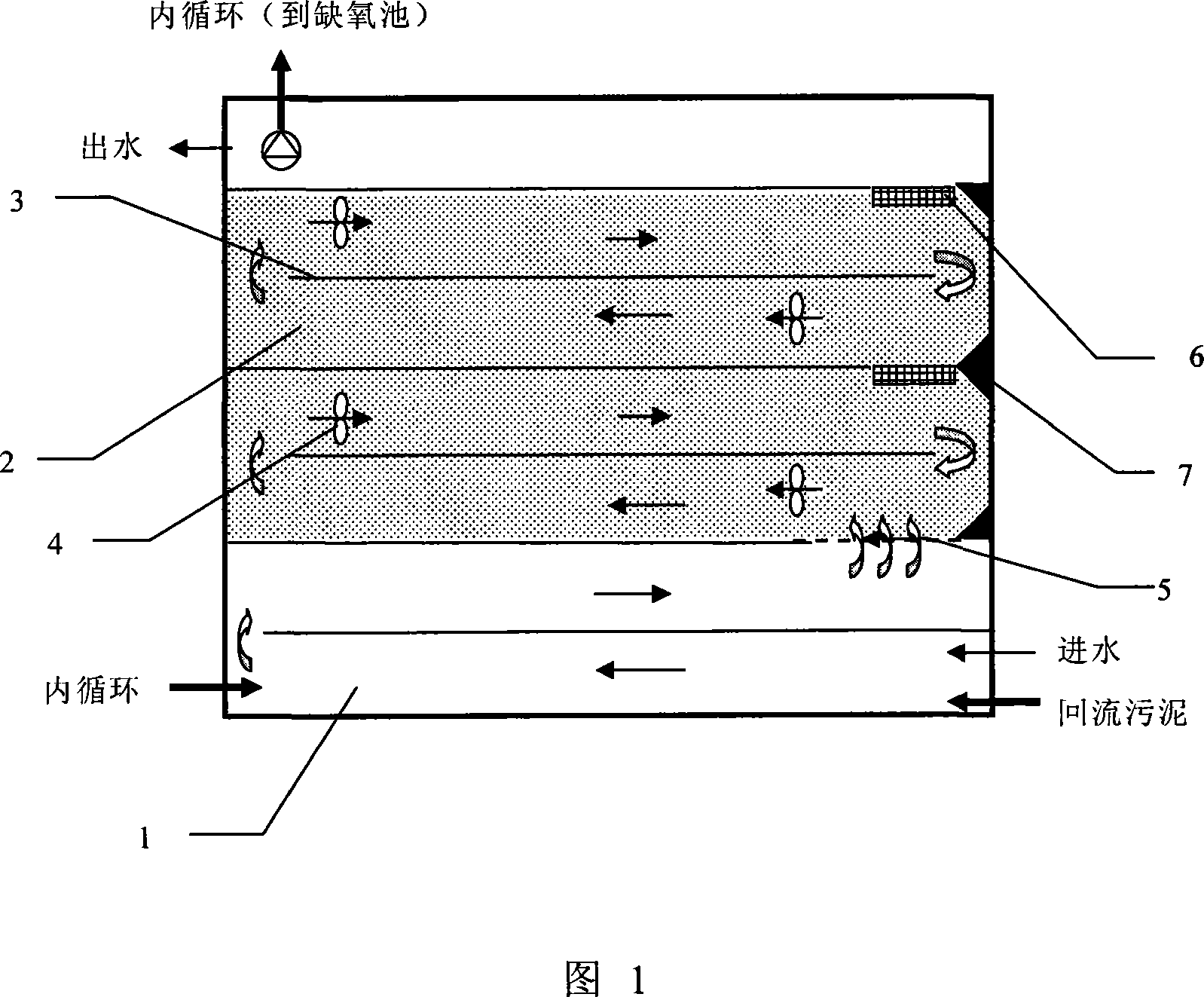

Multistage circulation composite sewage treatment method

InactiveCN101215044AIncrease biomassChange structureSustainable biological treatmentWater/sewage treatment by flocculation/precipitationPropellerSewage

The invention discloses a multi-stage combined-cycle sewage treatment method, which is adaptable to two-stage plug-flow urban sewage treatment plants. An aeration tank of the two-stage plug-flow urban sewage treatment plant is divided into an anoxic zone and an adding zone of suspension filling material, wherein the anoxic zone is arranged at the rear end of the aeration tank and communicated with a water inlet of the aeration tank and the adding zone of suspension filling material is arranged behind the anoxic zone. The adding zone of suspension filling material is divided into a plurality of processing units, each processing unit comprises two galleries, each gallery is internally equipped with a diving propeller, each processing unit is internally provided with a baffle wall, two ends of the baffle wall and two side walls of the aeration tank are provided with openings, and under the propelling of the diving propeller, suspension filling material and mixed liquor placed in the adding zone of suspension filling material circulate and flow along the galleries. The invention enables the sewage entering the adding zone of suspension filling material to realize multi-stage multi-time circulatory flow in the adding zone of suspension filling material, thereby increasing the effect of sewage treatment.

Owner:TIANJIN CAPITAL ENVIRONMENTAL PROTECTION GRP CO LTD

Mariculture wastewater treatment system and treatment method

ActiveCN106186548AImprove water transparencyReduce turbidityMultistage water/sewage treatmentTreatment involving sedimentationSeawaterChemistry

The invention relates to a mariculture wastewater treatment system and treatment method. The mariculture wastewater treatment system comprises a slanting board sedimentation pool and a three-section nitrogen and phosphorus removal pool which communicate with each other, wherein the three-zone nitrogen and phosphorus removal pool comprises a water distribution area, an anoxic zone, an aerobic zone, a phosphorous removal zone and a water collection area which are arranged in sequence, the anoxic zone is filled with gravel substrates, the aerobic zone is filled with zeolite substrates and equipped with a perforated aerator pipe, the phosphorous removal zone is filled with phosphorous removal functional filler substrates, a water inlet pipeline is arranged at the bottom end of the slanting board sedimentation pool, the top end of the slanting board sedimentation pool communicates with the water distribution area, the water collection area is equipped with a water outlet pipeline, and a return pipeline is arranged between the water collection area and the water distribution area, so that part of treated water is conveyed back to the water distribution area through the return pipeline. Compared with the prior art, the turbidity and the content of soluble COD, nitrogen and phosphorus in water can be reduced simultaneously, an A / O biological contact oxidation technology and an adsorption phosphorous removal technology are combined creatively to be applied to the field of seawater treatment, and the problem about large-scale purified emission of mariculture wastewater is solved.

Owner:SHANGHAI JIAO TONG UNIV

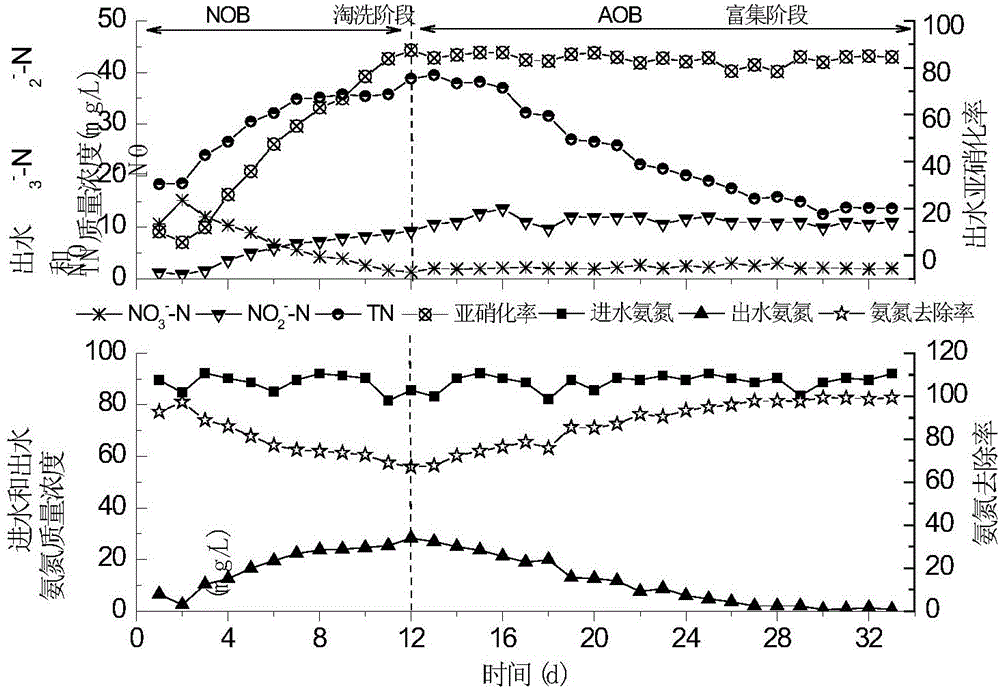

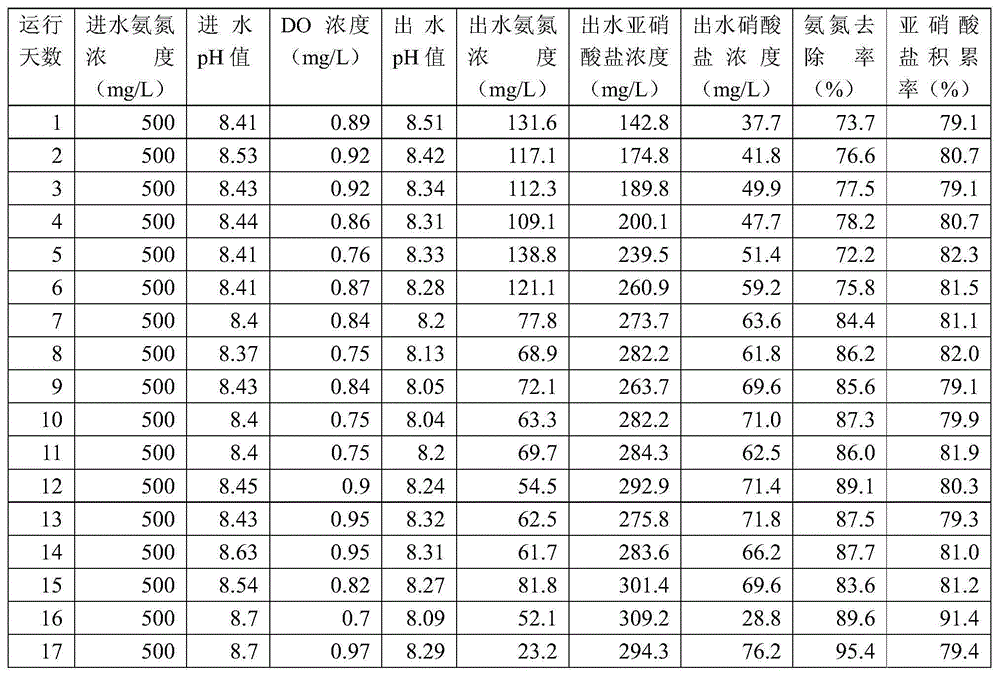

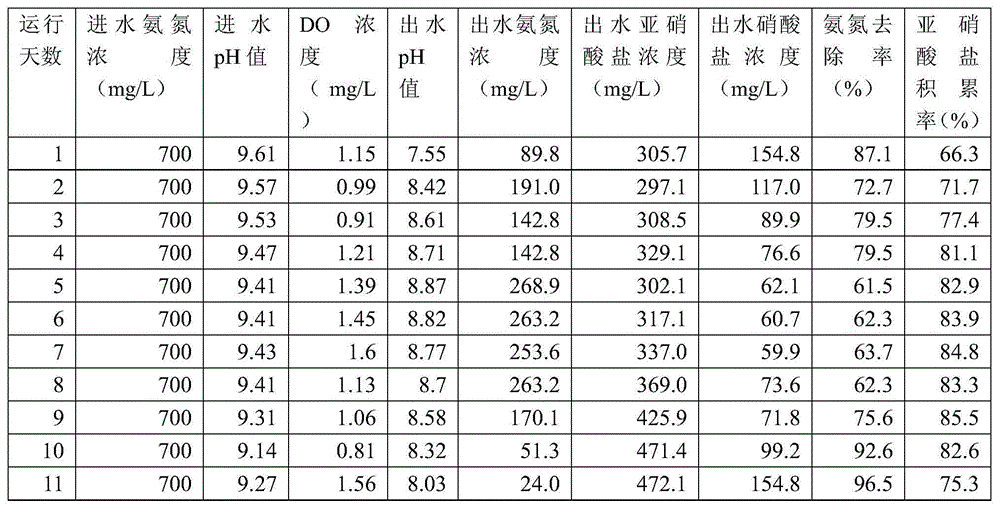

Normal-temperature low-C/N-ratio sewage continuous shortcut nitrification starting method

ActiveCN103951057ASuccessful enrichmentImprove removal efficiencyTreatment with aerobic and anaerobic processesWater dischargeSludge

The invention relates to a normal-temperature low-C / N-ratio sewage continuous shortcut nitrification starting method, and belongs to the sewage treatment and regeneration field. The method comprises the following steps: dividing the aerobic zone of an A<2>O reactor into three segments comprising an aerobic segment 1, an aerobic segment 2 and an aerobic segment 3 along a water flow direction, and refluxing a nitrification liquid to an anoxic zone from the aerobic segment 3; and inoculating nitrated sludge into the reactor until the concentration of sludge in the reactor is 2.5-3g / L, rapidly elutriating nitrite oxidation bacteria (NOB) with continuous flow short-sludge-age water at a water temperature of 23-25DEG C, screening ammonia-oxidizing bacteria (AOB), adding a cylindrical polypropylene suspension filler into an aerobic zone, recovering the long sludge age, reducing the dissolved oxygen concentration of the aerobic zone, and maintaining the above conditions until the mass concentration of ammonia nitrogen in water discharged from the A<2>O reactor decreases to below 2mg / L and the nitrosification rate stably maintains above 80% in order to complete the continuous shortcut nitrification starting. The starting method realizes the advanced treatment of the N element through shortcut nitrification denitrification, and is simple and feasible.

Owner:BEIJING UNIV OF TECH

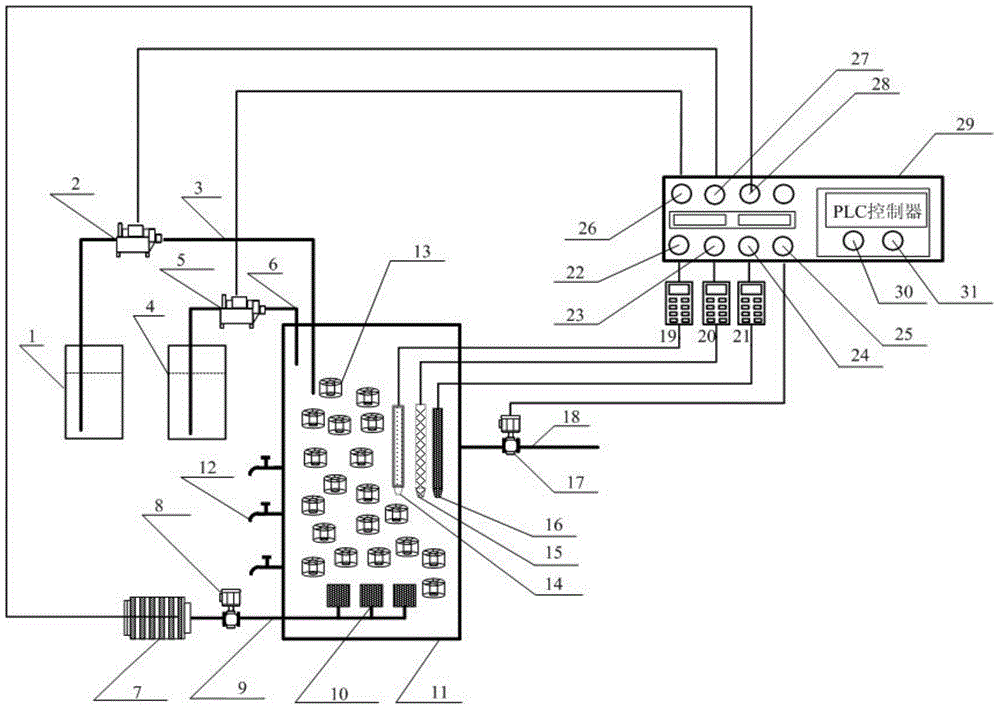

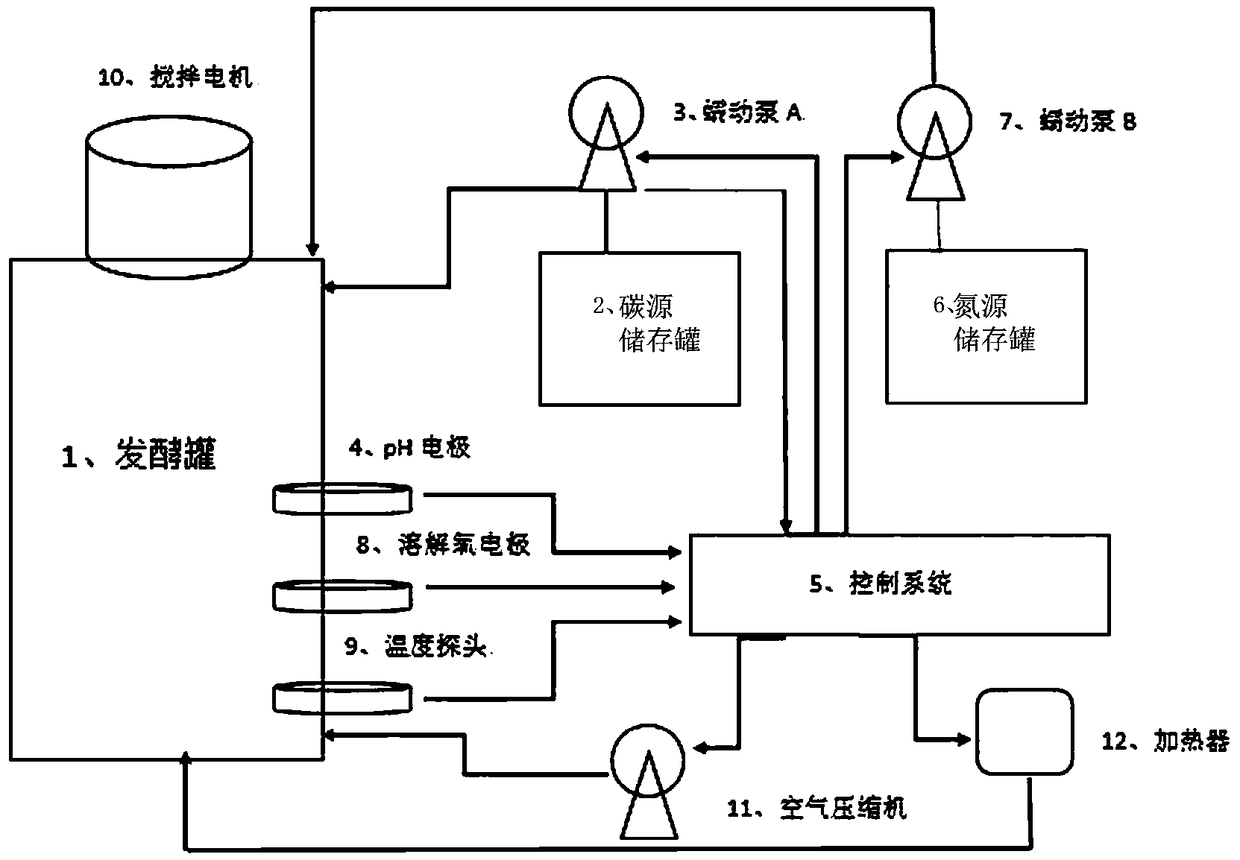

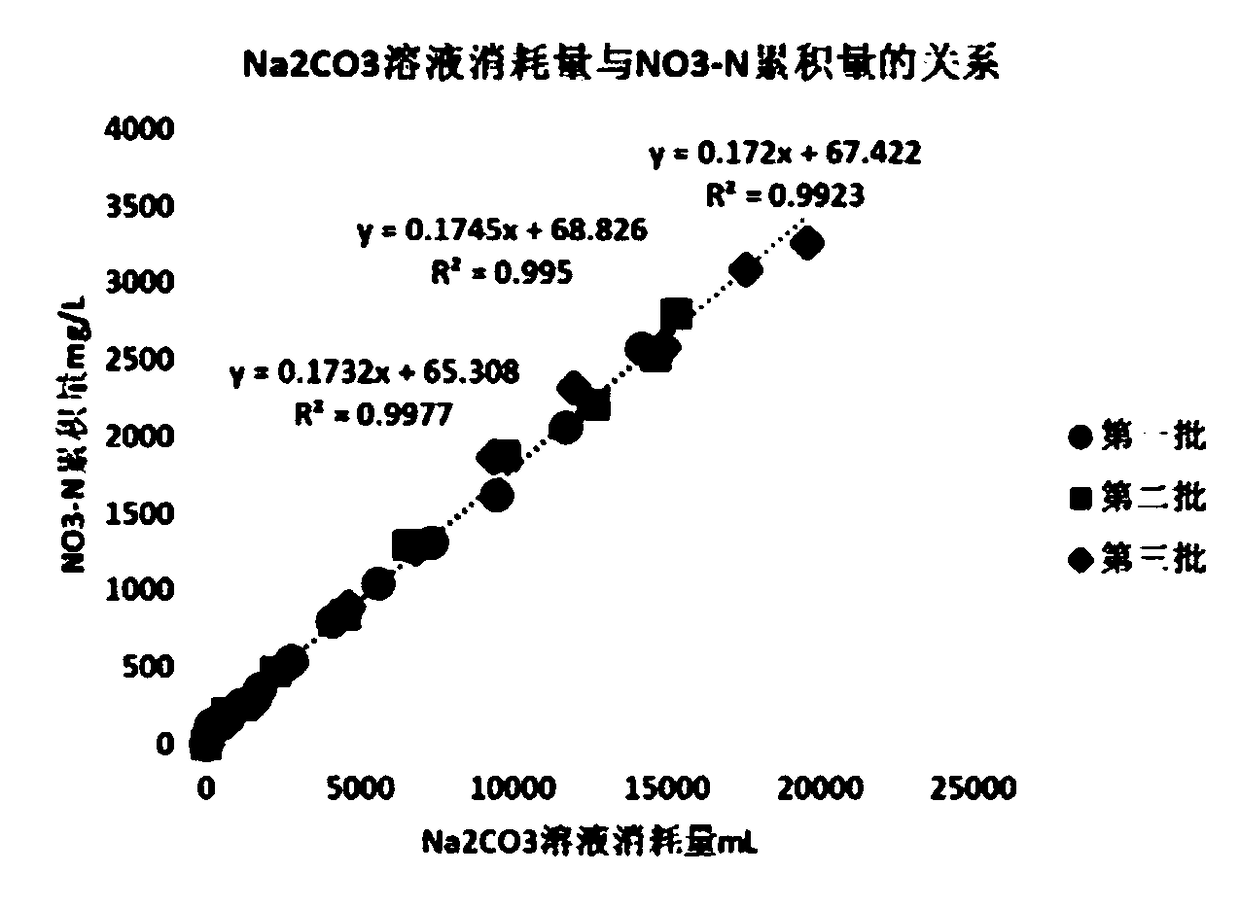

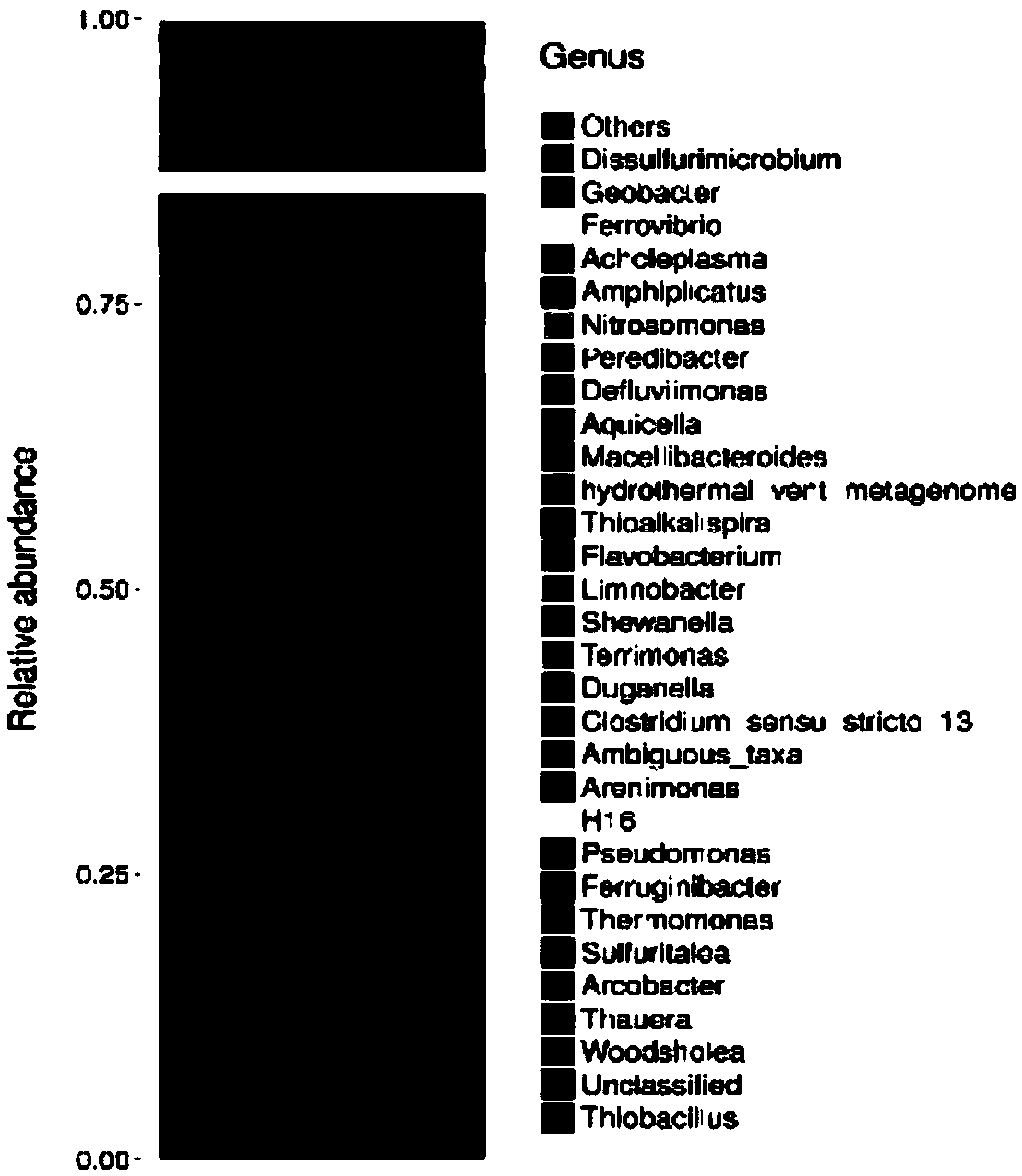

High-density enriching method of autotrophic nitrifying bacterial consortium

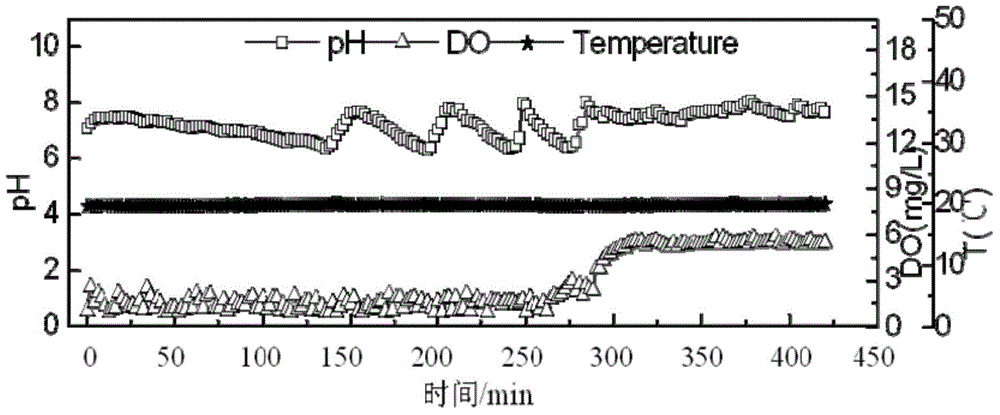

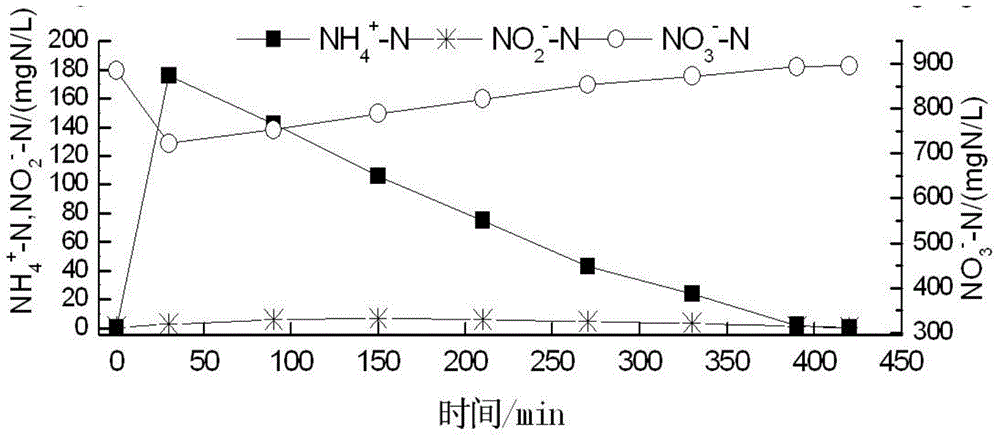

ActiveCN109055285AImprove nitrification capacitySolve the problem of ammonia nitrogenBacteriaBiological water/sewage treatmentCarbon sourceSewage treatment

The invention belongs to the field of microbial fermentation and specifically relates to a high-density enriching method of an autotrophic nitrifying bacterial consortium and application of the obtained autotrophic nitrifying bacterial consortium to sewage treatment. The high-density enriching method of the autotrophic nitrifying bacterial consortium comprises the steps of inoculating thalli in anautotrophic nitrifying bacteria initial culture medium; culturing the thalli under a stirring condition by controlling the dissolved oxygen (DO) at 20-40%, at the temperature of 28-32 DEG C and the pH value of 7.5-8.0; according to a relation between NO3-N cumulated amount and inorganic carbon source consumption in the culturing process, monitoring the change of pH value in the culturing processby a pH electrode to supplement an inorganic nitrogen source and the inorganic carbon source to a culture system, and controlling the ammonia nitrogen concentration in the culturing process at 150-300mg / L; and enabling the pH value of the system to be 7.5-8.0 by the supplemented carbon source to further realize high-density automatic propagation of the autotrophic nitrifying bacterial consortium.The high-density enriching method of the autotrophic nitrifying bacterial consortium, provided by the invention, has the advantage that a problem of the consortium of poor ammonia-nitrogen treating effect caused by reasons, such as poor strain adaptation ability, added strain loss, insufficient added strain number and high cost, in the ammonia-nitrogen waste water treatment application process iseffectively solved.

Owner:SHENYANG RES INST OF CHEM IND +1

Aeration biological filter pool device and process for efficiently denitrifying and dephosphorizing

InactiveCN101857345ASimple processEmission reductionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated sludgeBiological filter

The invention relates to an aeration biological filter pool device and a process for efficiently denitrifying and dephosphorizing in the sewage treatment and provides an aeration biological filter pool device for efficiently denitrifying and dephosphorizing. The aeration biological filter pool device comprises water feeding pumps which are connected and arrayed according to water feeding sequence, a synchronous denitrification dephosphorizing pool for synchronously denitrifying and dephosphorizing water from the water feeding pumps, a settling pond for settling the water from the synchronous denitrification dephosphorizing pool, an aeration biological filter pool water feeding pump and an aeration biological filter pool, wherein the synchronous denitrification dephosphorizing pool adopts a activated sludge process. The invention also provides an aeration biological filter pool process for efficiently denitrifying and dephosphorizing. The invention has the beneficial effects of solving the problems of complicated pretreatment, frequent back flush and insufficient utilization on a raw water carbon source of the conventional aeration biological filter pool, reducing the emission of carbon dioxide, improving the utilization rate of structures and reducing the occupied area and the cost by optimizing a process flow and being beneficial to wide application of the aeration biological filter pool process.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

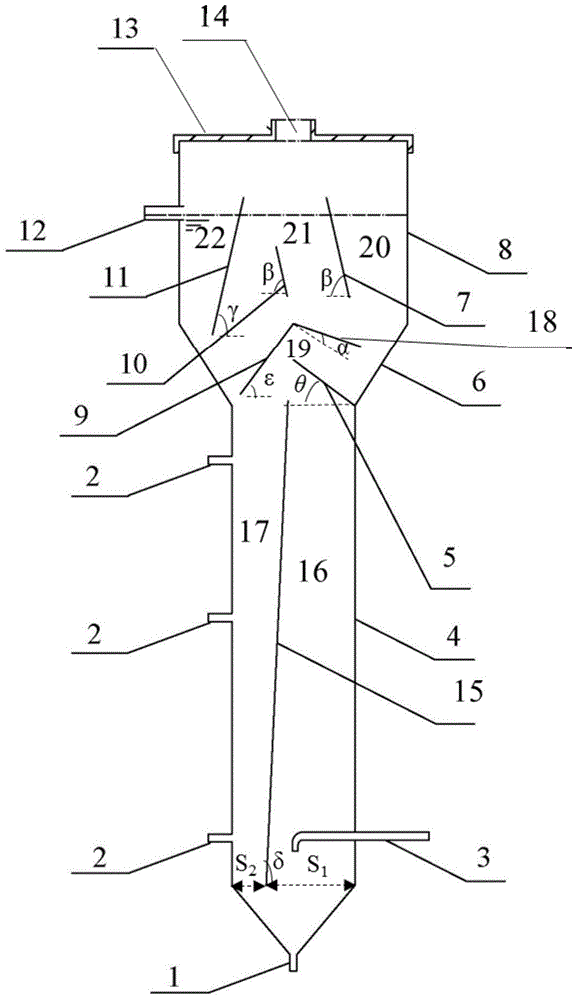

Air lift type bio-nitrification reactor with baffle plate reinforcing internal circulation

ActiveCN104478079AEasy to separateStrong resistance to shock loadsTreatment using aerobic processesSustainable biological treatmentLoad resistanceSludge

The invention discloses an air lift type bio-nitrification reactor with a baffle plate reinforcing internal circulation. The air lift type bio-nitrification reactor with the baffle plate reinforcing internal circulation comprises a reaction chamber and a sedimentation chamber which are arranged from bottom to top, wherein the reaction chamber is connected with the sedimentation chamber by virtue of a funnel-shaped diffusion tube, a water inlet pipe is arranged at the bottom of the reaction chamber, a gas guiding pipe and a sampling pipe which are inserted into the center of the reaction chamber are arranged on the side wall of the reaction chamber, the interior of the reaction chamber is divided into an upflow region and a flow falling region by virtue of a separating baffle, a baffling region formed by the baffle plate is arranged in the diffusion tube, a gas releasing baffling sloping plate, a flow reducing baffling sloping plate and a water yielding baffling sloping plate are arranged in the sedimentation chamber, the sedimentation chamber is divided into a gas releasing region, a slow flow region and a water discharging region, the water discharging region is connected with a water discharging pipe, and an air hole is formed in the top of the sedimentation tank. The air lift type bio-nitrification reactor with the baffle plate reinforcing internal circulation has the advantages that mud, water and gas three-phase circulation in the reaction chamber can be reinforced, and oxygen utilization efficiency is improved; elution of sludge can be effectively avoided, and high biological sludge content in the reactor is maintained; and good impact load resistance and high nitrification performance can be realized.

Owner:CENT SOUTH UNIV

Tidal vertical flow wastewater treatment system and method

InactiveUS20060237363A1Good conditionSmall treatment footprintWater cleaningTreatment using aerobic processesBiofilmPlant roots

A wastewater treatment system includes a tidal, sequential vertical flow marsh cell system having at least three marsh cells in serial forward fluid communication. Incoming wastewater to be treated is channeled to at least the first and a second marsh cell, and a portion of water exiting a final marsh cell, to the first marsh cell surface. Each marsh cell is alternately flooded and drained for enhancing aeration of incoming water and marsh cell contents, which include media and plant roots having biofilms growing thereon, the biofilms including a population of nitrifying and denitrifying bacteria, for achieving substantially simultaneous nitrification and denitrification of the wastewater.

Owner:IASIS USA LC +1

Artificial oxygenation type composite underflow wet land sewage purification process

InactiveCN101333029AEasy to handleImprove purification effectSustainable biological treatmentBiological water/sewage treatmentDecompositionSewage

The invention relates to an artificial oxygen increasing type combined subsurface flow wetland sewage purification technique, belonging to the field of water pollution control; aiming at the defects of artificial wetlands such as easy blockage, low purification capability and large seasonal fluctuation, a sewage purification technique which includes a biological strengthening sedimentation tank, a micro aeration vertical flow wetland and a subsurface horizontal-flow wetland is developed. The biological strengthening sedimentation tank can reduce the concentration of suspended substances, and the micro aeration vertical flow wetland can improve oxidative decomposition and nitrification effect of organic matter, can reduce the organic residue in a wetland system to the maximum extent and prolong the service life of the wetland. The subsurface horizontal-flow wetland can create an anoxia-anaerobic environment for the effluent of the micro aeration vertical flow; therefore, denitrification can be carried out more completely. The technique is applicable to the treatment of the domestic sewage from villages, small towns and scenic spots and the sewage entering lakes and rivers which is mixed with urban domestic sewage, and the deep purification of the tail water of sewage treatment plants.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Urban sewage strengthening treatment method in cold area based on multi-point feed water adjustment

InactiveCN102001791AExtended staySmall volumeMultistage water/sewage treatmentNitrogenTherapeutic effect

The invention discloses an urban sewage strengthening treatment method in a cold area based on multi-point feed water adjustment, which relates to an urban sewage strengthening treatment method and solves the problems of incapability of synchronous and efficient denitrogenation and dephosphorization, poor treatment effect, high running cost and unsuitability for treating urban sewage in the cold area in the traditional technology of treating the urban sewage. The method comprises the following steps of: firstly, primary precipitation of sewage: dividing effluent of a primary settling tank into two parts or three parts through a distribution well for distribution; and secondly, synchronously introducing the effluent mixing liquid of an anaerobic tank and an anoxic tank 1 and the reflowing sludge at the head end of an aerobic tank into the aerobic tank, introducing the effluent of the aerobic tank into an anoxic tank 2, introducing the effluent of the anoxic tank 2 into a secondary settling tank through water drop, discharging a supernatant as treated purified water, reflowing a part of sludge at the lower layer, and discharging the rest as the remaining sludge. The invention can synchronously carry out efficient denitrogenation and dephosphorization, has favorable treatment effect and low running cost and is suitable for treating the urban sewage in the cold area.

Owner:HARBIN INST OF TECH

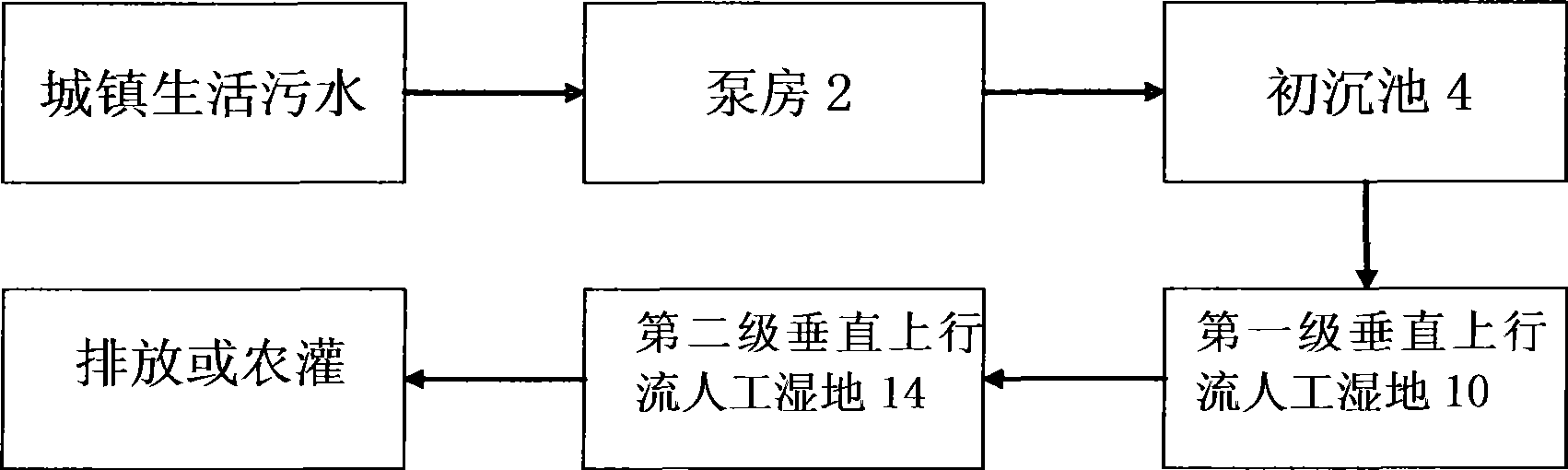

Method for processing town sewage using composite vertical current artificial marshland and apparatus thereof

ActiveCN101386451AEasy to interceptImprove filtering effectSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandAgricultural irrigation

This invention discloses a method and a device for the treatment of urban domestic sewage by composite vertical current constructed wetlands. The method connects two levels of vertical upstream current constructed wetlands in series for the treatment of urban domestic sewage; firstly, the urban domestic sewage enters a primary sedimentation tank, and enters a level I vertical upstream current constructed wetland and a level II vertical upstream current constructed wetland in sequence after pre-sedimentation; the ultimate effluent can be used for agricultural irrigation or be discharged into rivers. The invention, which connects the two levels vertical upstream currents in series for the treatment of urban domestic sewage, are characterized by powerful detergency, strong nitrification and denitrification capacity, little water potential loss and low energy-consumption requirement; accordingly, the required falls of water between the pretreatment tank and the level I constructed wetland and between the two levels of constructed wetlands are small. The method of the invention can utilize the composite vertical upstream currents to efficiently improve the resistance to the external temperature impact and keep satisfactory effect of removing contaminants in winter. The device is simple in structure, which is helpful for large-scale promotion.

Owner:SOUTH CHINA AGRI UNIV

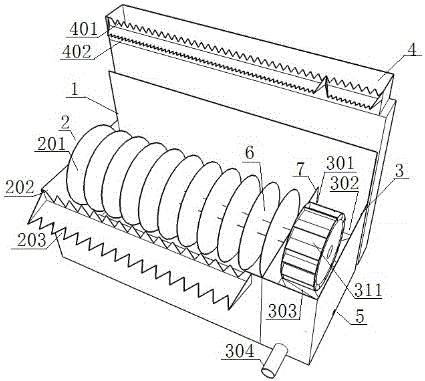

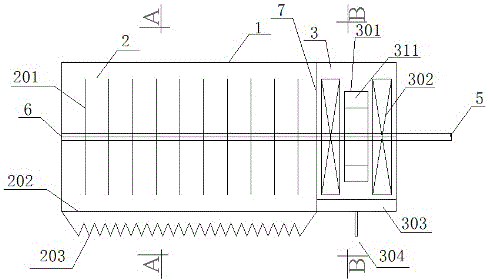

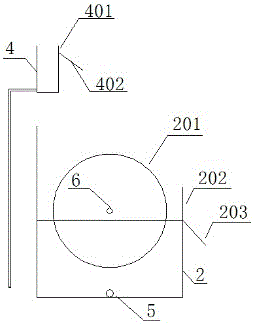

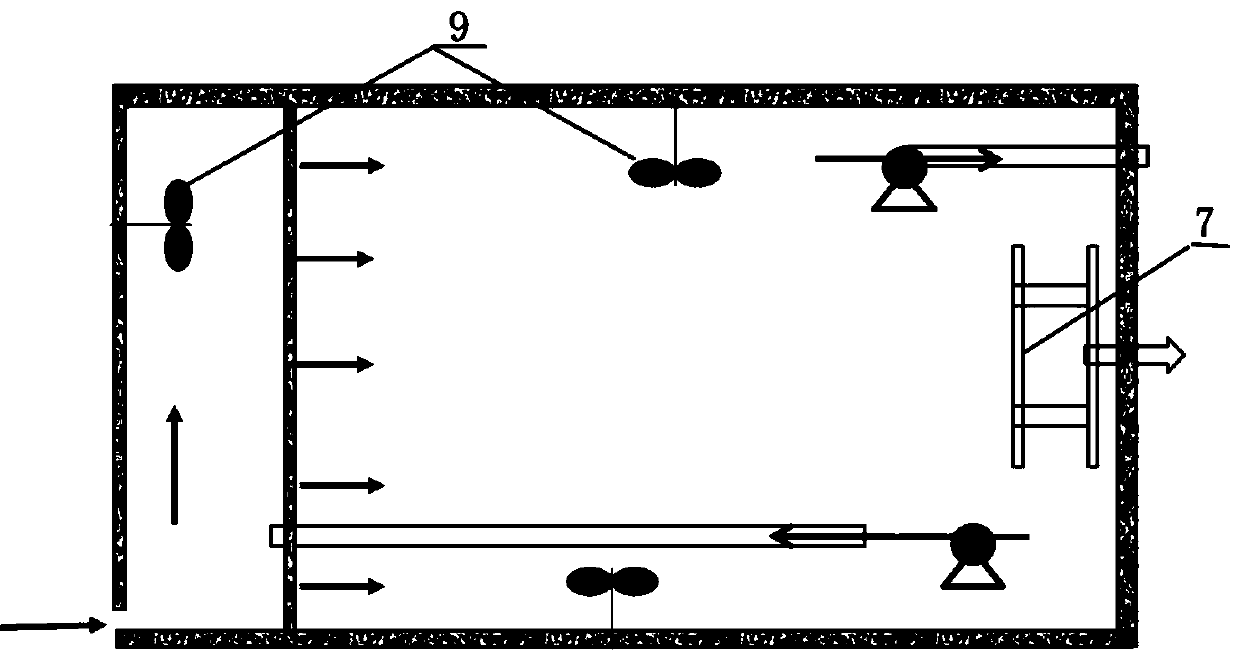

Combined drop-driven biological rotating disk reactor

ActiveCN105712472AIncrease speedEliminate resistanceTreatment using aerobic processesBiological treatment apparatusSewageControl theory

The invention discloses a combined drop-driven biological rotating disk reactor which comprises a tank body (1), wherein the tank body (1) comprises a rotating disk region (2) and a drive region (3); a rotating disk (201) is arranged in the rotating disk region (2) through a rotating shaft (6); a drive disk (301) for driving the rotating disk (201) to rotate is arranged in the drive region (3); the liquid level of the drive region (3) is arranged below the drive disk (301); the bottom of the drive region (3) is provided with an auxiliary filler oxidation region (302) for degrading the sewage; and the front end of the auxiliary filler oxidation region (302) is provided with a water outlet tank (303) for controlling the liquid level of the drive region (3). By adopting the drive disk and rotating disk function division, the liquid level of the drive region is on the bottom of the drive disk, thereby eliminating the resistance of water to the drive unit, enhancing the rotation speed of the rotating disk, and obviously enhancing the oxygenation rate. The auxiliary oxidation filler region is utilized to reinforce the removal of organic substances in the sewage, thereby being beneficial to enhancing the nitrification properties of the reactor.

Owner:SOUTHEAST UNIV

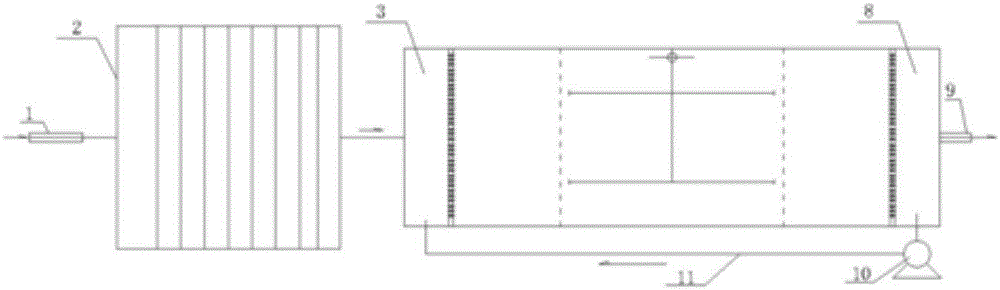

Method for upgrading expansion biochemical pool on basis of MBBR technology

PendingCN107601669AGood removal effectEnhanced denitrification reactionWater contaminantsTreatment with aerobic and anaerobic processesRefluxNitration

The invention discloses a method for upgrading an expansion biochemical pool on the basis of MBBR technology and belongs to the field of sewage treatment. The expansion biochemical pool comprises an anaerobic zone, an MBBR mud film anoxic zone, an MBBR mud film aerobic zone and a decanting water draining zone, wherein a water feeding hole is formed in the anaerobic zone; the anaerobic zone communicates with the MBBR mud film anoxic zone through a through hole at the bottom of a first zone separating wall; a suspension carrier is added into the MBBR mud film anoxic zone; another suspension carrier is added into the MBBR film mud aerobic zone; the MBBR mud film aerobic zone communicates with the MBBR mud film anoxic zone through a front intercepting screen; a penetrated aerator pipe is arranged in the MBBR mud film aerobic zone; the MBBR mud film aerobic zone communicates with the decanting water draining zone through a rear intercepting screen; the decanting water draining zone communicates with the anaerobic zone and the MBBR mud film anoxic zone through a water draining pipeline of a nitration liquid reflux pump. According to the invention, on the basis of keeping the running modeof an original CAST biochemical pool, the MBBR technology is adopted for rezoning transformation, so that the nitrogen and phosphorus removal capacity of the original CAST biochemical pool is promoted.

Owner:济宁市孚源环保科技有限公司

Activated sludge for treating crushed coal gasification wastewater and culturing domestication method and application of activated sludge

ActiveCN109775855AEasy to handleImprove adaptabilityWater contaminantsTreatment with aerobic and anaerobic processesActivated sludgeCoal gasification wastewater

The invention relates to activated sludge for treating crushed coal gasification wastewater and a culturing domestication method and application of the activated sludge. The culturing domestication method comprises the following steps that 1, a culture solution is added into an A / O tank, the activated sludge is put into the culture solution for closed aeration, and the activated sludge is culturedthrough intermittent aeration; 2, the activated sludge obtained after being cultured through intermittent aeration in the step 1 is domesticated through intermittent aeration; 3, the activated sludgeobtained after being domesticated through intermittent aeration in the step 2 is domesticated through continuous aeration. The activated sludge cultured and domesticated by using the method has gooddegrading effects on CODcr, ammonia nitrogen and total phenols, wherein the removal rate of the CODcr is up to 93.5%, the removal rate of the NH3-N is up to 98.3%, and the removal rate of the total phenols is up to 93%.

Owner:中海油山西能源投资有限责任公司

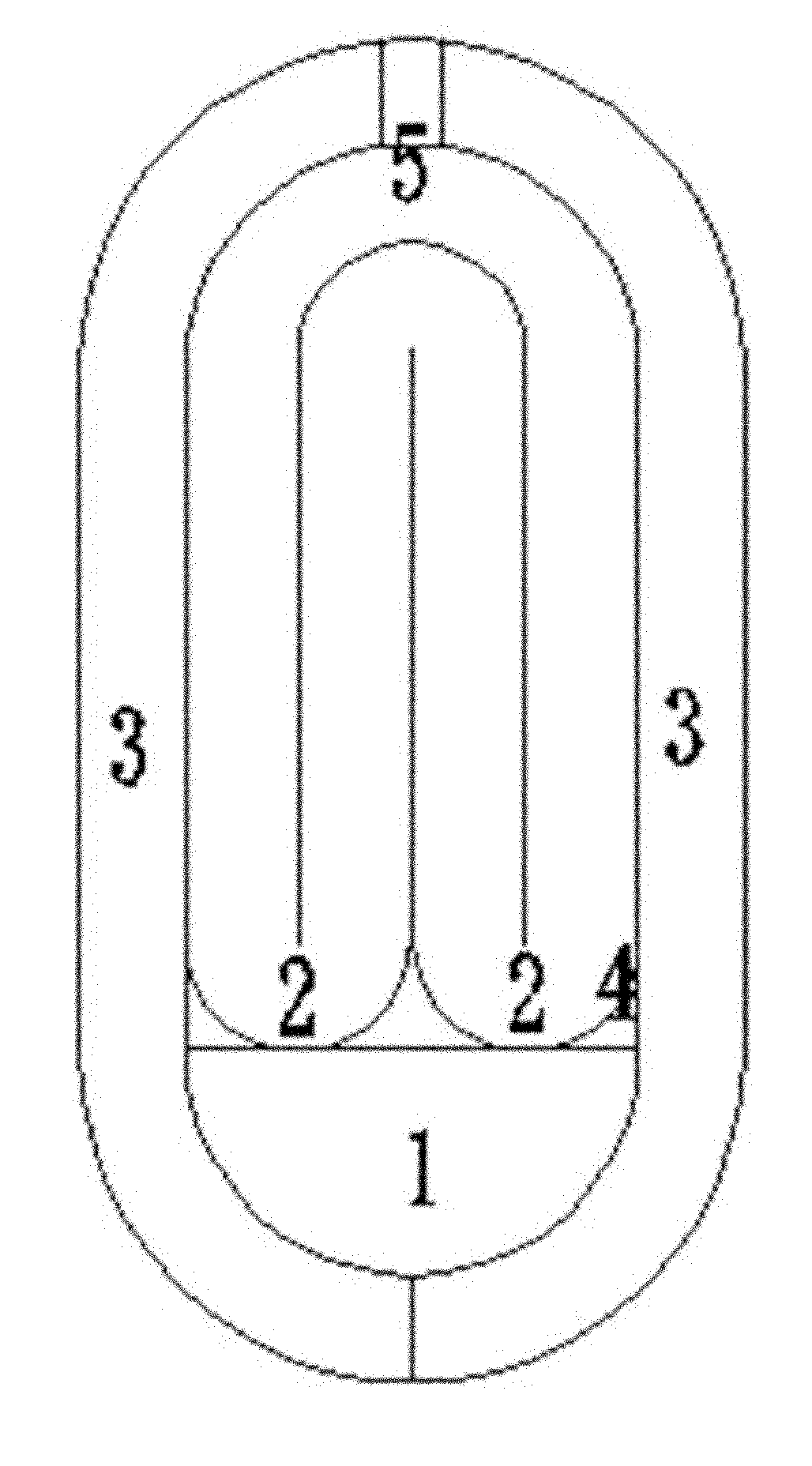

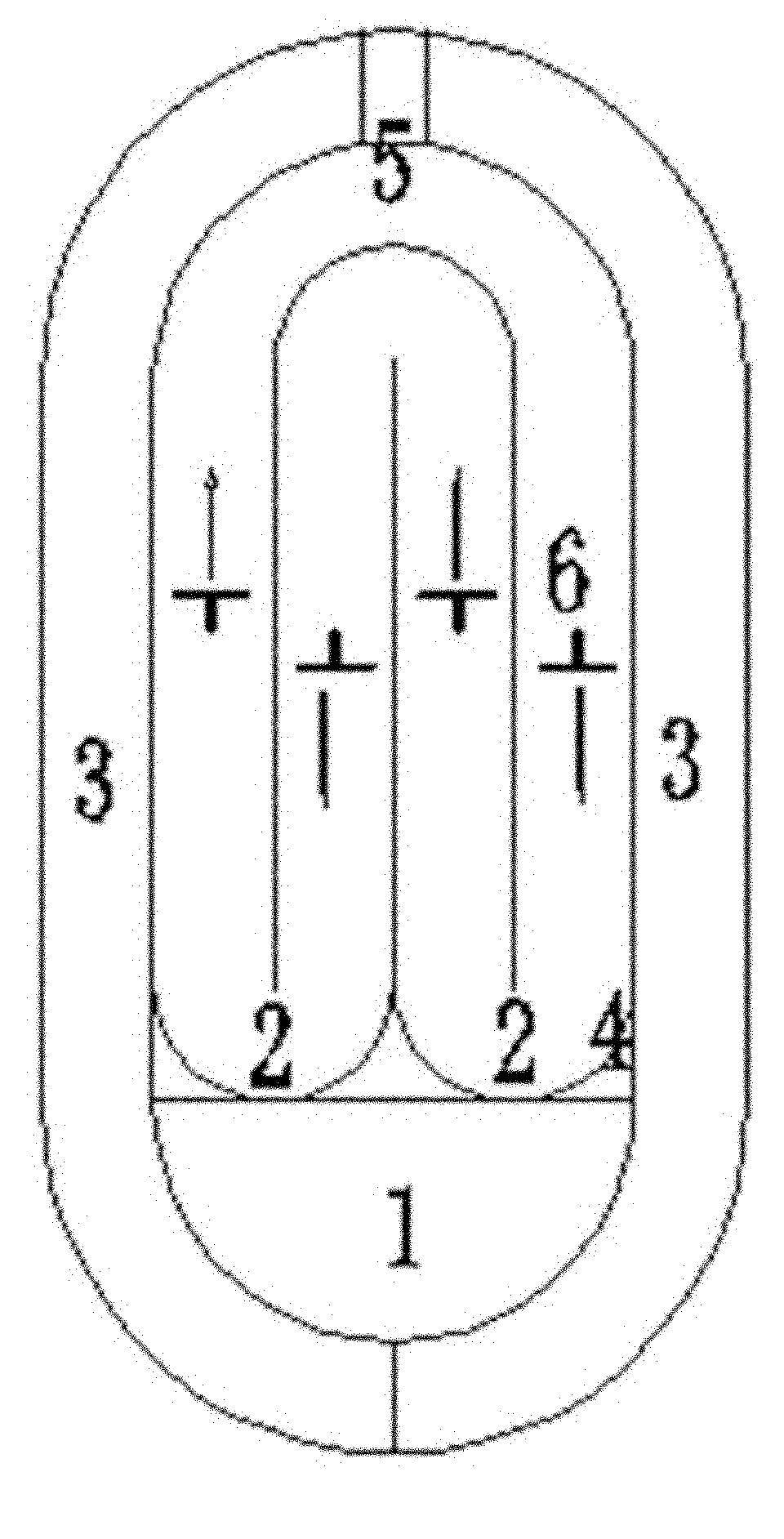

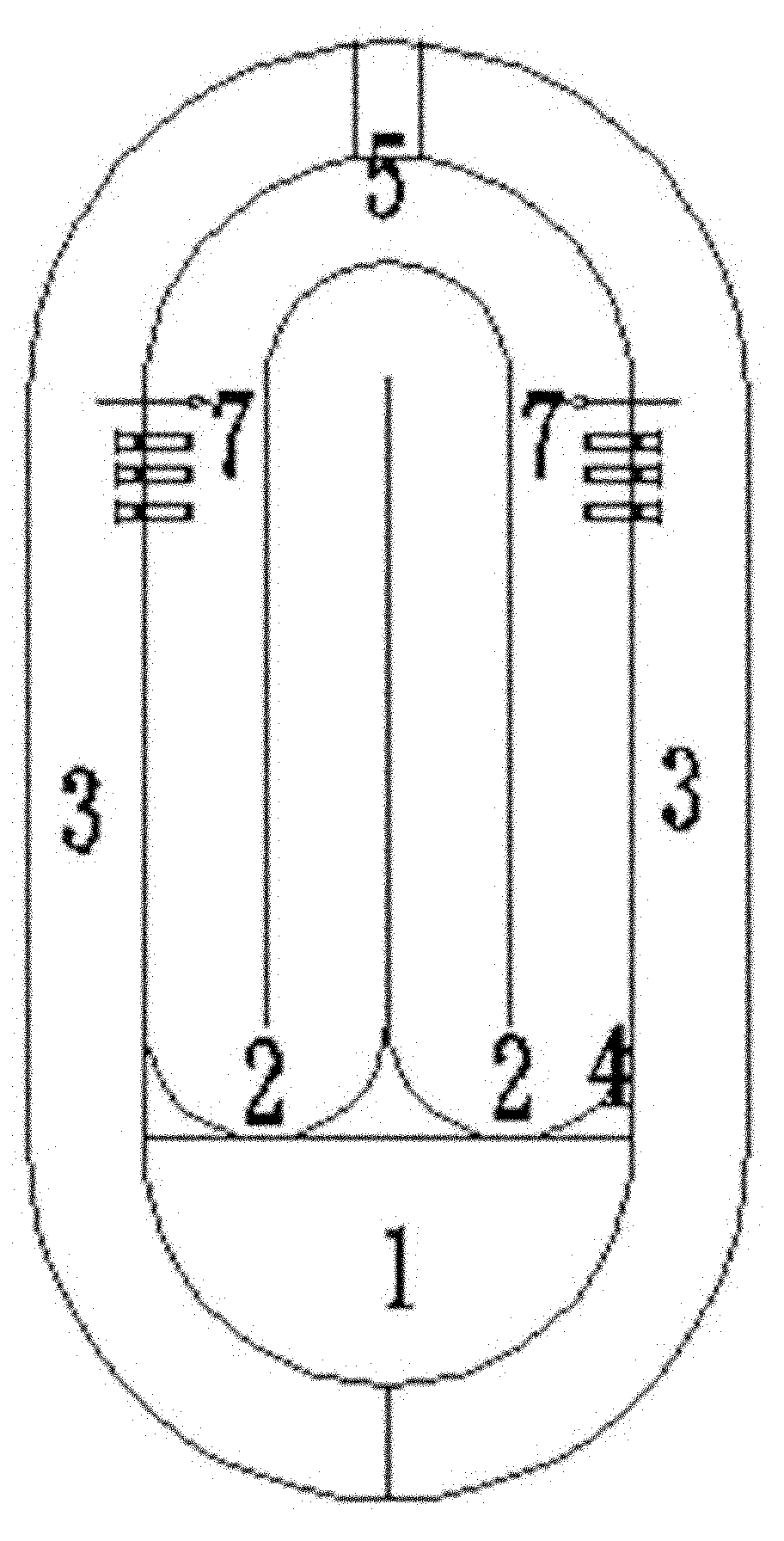

Combined SBR-Carrousel oxidation ditch high-efficiency denitrification process

ActiveCN101955308ASmall footprintLow investment costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentOperating costWater treatment

The invention belongs to the technical field of water treatment, and in particular relates to a combined SBR-Carrousel oxidation ditch high-efficiency denitrification process. In the combined SBR-Carrousel oxidation ditch high-efficiency denitrification process, an oval Carrousel oxidation ditch and SBR pools are provided, wherein an anoxic zone is arranged at the top end of an aerobic zone of the Carrousel oxidation ditch, so that the volume of the pool is fully utilized; two SBR pools are respectively arranged on the two sides of the Carrousel oxidation ditch and share an outer pool wall with the Carrousel oxidation ditch; and the two SBR pools alternately run, can strengthen denitrification and realize the separation of mud and water and are used as a secondary sedimentation tank. Compared with the prior art, the process has the advantages that: the anoxic zone and the aerobic zone of the Carrousel oxidation ditch and the SBR pools are integrated, and the secondary sedimentation tank is saved; and the Carrousel oxidation ditch and the SBR pools share the pool wall, so floor area is obviously reduced, free space of the Carrousel oxidation ditch is fully utilized, a pipeline, a pump, a valve system, an internal return system and the like of a singly constructed facility are saved and investment cost and operating cost are greatly reduced.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

Low-carbon source two-stage MBR (Membrane-Bioreactor) enhanced nitrogen and phosphorus removal method for city sewage

InactiveCN106673371AAvoid easy cloggingEfficient separationTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesWater dischargeNitration

The invention discloses a low-carbon source two-stage MBR (Membrane-Bioreactor) enhanced nitrogen and phosphorus removal method for city sewage. The method is characterized by being a continuous flow nitrogen and phosphorus removal process with an adjusting tank, an anaerobic tank, a settling pond I, an aerobiotic MBR tank I, an anoxic pond, a settling pond II and an aerobiotic MBR tank II which are connected in series. The method comprises the following steps: firstly, feeding sewage into the anaerobic tank for anaerobic phosphorus release, further feeding the sewage into the settling pond I for sludge-water separation, feeding supernate obtained after settling into the aerobiotic MBR tank I for nitration and degradation of a part of organic matters, feeding settled sludge and a nitration liquid after aerobiotic nitration into the anoxic pond for denitrification phosphorus removal, feeding a part of a mixed liquid after anoxia into the settling pond II for settling sludge removal so as to remove phosphorus, feeding another part of the mixed liquid and the supernate of the settling pond II into the aerobiotic MBR tank II for further aerobiotic nitration and phosphorus removal, and finally filtering and discharging water by using an MBR membrane component. Due to two stages of aerobiotic MBRs, complete separation of nitration bacteria and phosphorus-accumulating bacteria can be achieved, the nitrogen and phosphorus removal effect can be improved, the process is simple in procedure and convenient to operate, and continuous water discharge can be achieved.

Owner:CHINA UNIV OF MINING & TECH

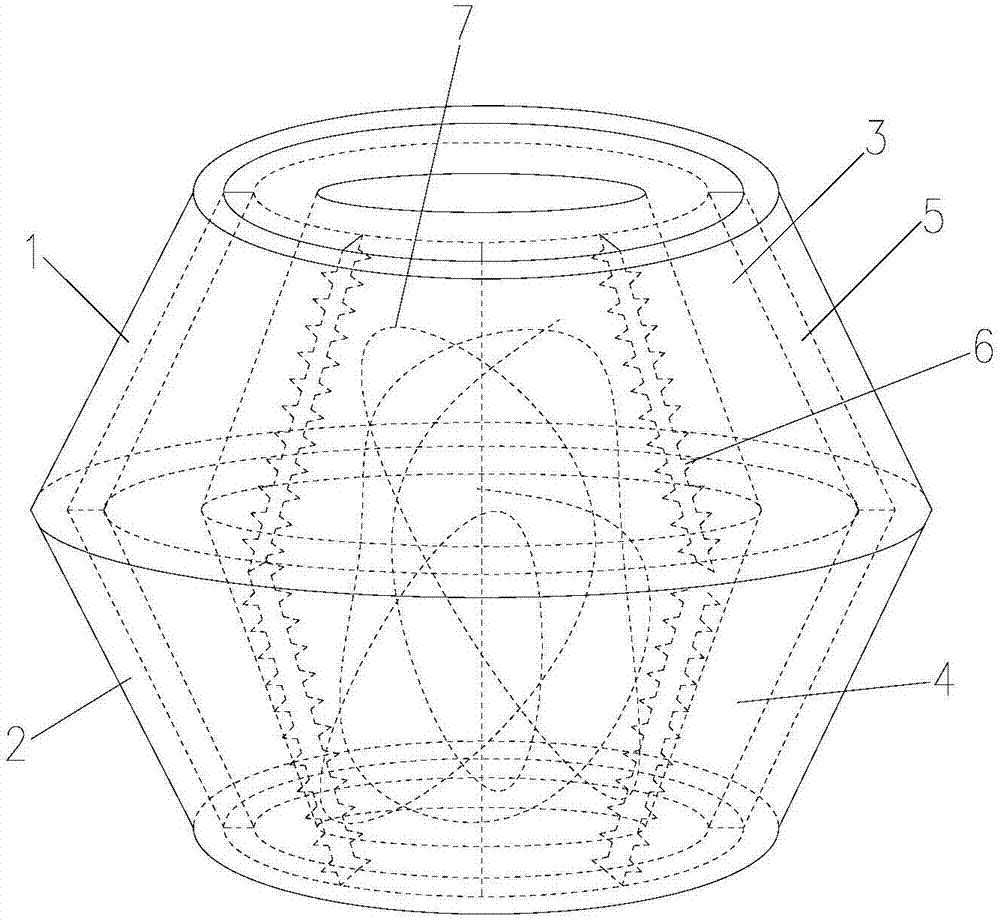

Suspended filler used for sewage treatment and preparation method thereof

ActiveCN107529522AImprove catalytic performancePromote nitrificationSustainable biological treatmentBiological water/sewage treatmentFiberAdditive ingredient

The invention provides suspended filler used for sewage treatment and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing the following componentsin parts by mass: 4-10 parts of activated carbon powder, 8-11 parts of reclaimed rubber powder, 1-3 parts of purified diatomite, 1-7 parts of maleic anhydride, 0.3-0.9 part of dicumyl peroxide and 0.5-2 parts of biological enzyme, then adding 75-80 parts of high-density polyethylene, and stirring at a high speed; (2) adding the mixed materials into a suspended filler mold, and molding; (3) settingthe molded suspended filler, cooling, carrying out mechanical perforation, and cutting by virtue of a gear; and (4) finally adding a silk-like fiber carrier at the center. The suspended filler provided by the invention has the advantages that enhancement ingredients are added for biological enzyme, hydrophilic modification is carried out, catalytic action of the biological enzyme and nitrification of nitrifying bacteria are promoted, and hydrophilic performance of the filler and nitrification ability of the nitrifying bacteria are improved, so that microorganisms can be adsorbed on the fillereasily, and capabilities of the microorganisms in decomposition on pollutants in water and removal of ammonia nitrogen are obviously improved.

Owner:重庆淏园环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com