High-density enriching method of autotrophic nitrifying bacterial consortium

A technology of nitrifying bacteria and nitrosifying bacteria, which is applied in chemical instruments and methods, bacteria, biological water/sewage treatment, etc., can solve the problems of automatic supplementation and the impact of carbon source supplementation, and achieve The effect of improving nitrification ability and solving ammonia nitrogen problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

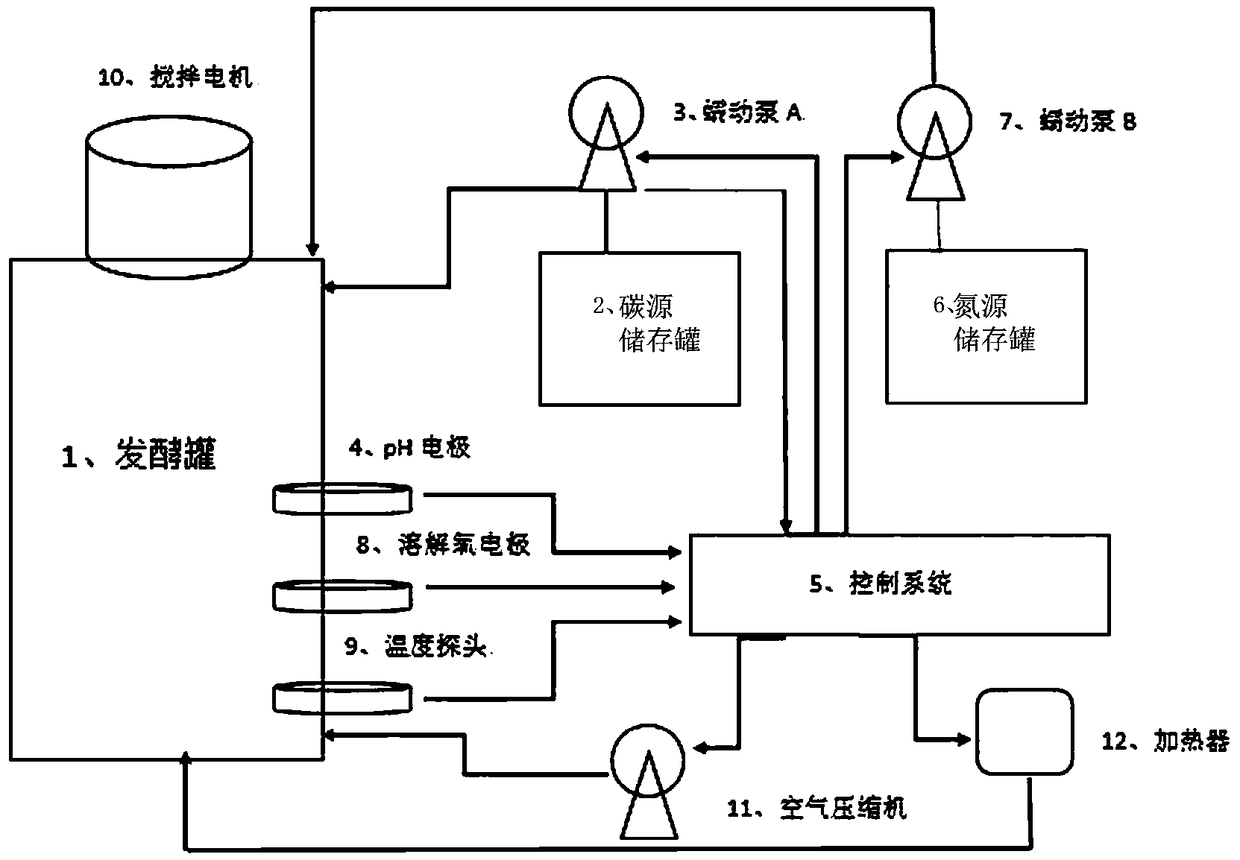

[0030] The reaction device includes a fermenter, a carbon source storage tank, a peristaltic pump A, a pH electrode, a control system, a nitrogen source storage tank, a peristaltic pump B, a dissolved oxygen electrode, a temperature probe, a stirring motor, an air compressor, and a heater. The fermenter is inserted with a pH electrode, a dissolved oxygen electrode and a temperature probe, and the pH electrode, the dissolved oxygen electrode and the temperature probe are respectively connected to the control system through wires, and the fermenter is respectively connected to the external mixer, peristaltic pump A, and peristaltic pump B through wires. , the air compressor and the heater are connected, and the peristaltic pump A, peristaltic pump B, air compressor and heater are respectively connected to the control system through wires. In addition, the peristaltic pump A is connected to the carbon source storage tank and the peristaltic pump through pipelines. B passes through...

Embodiment 2

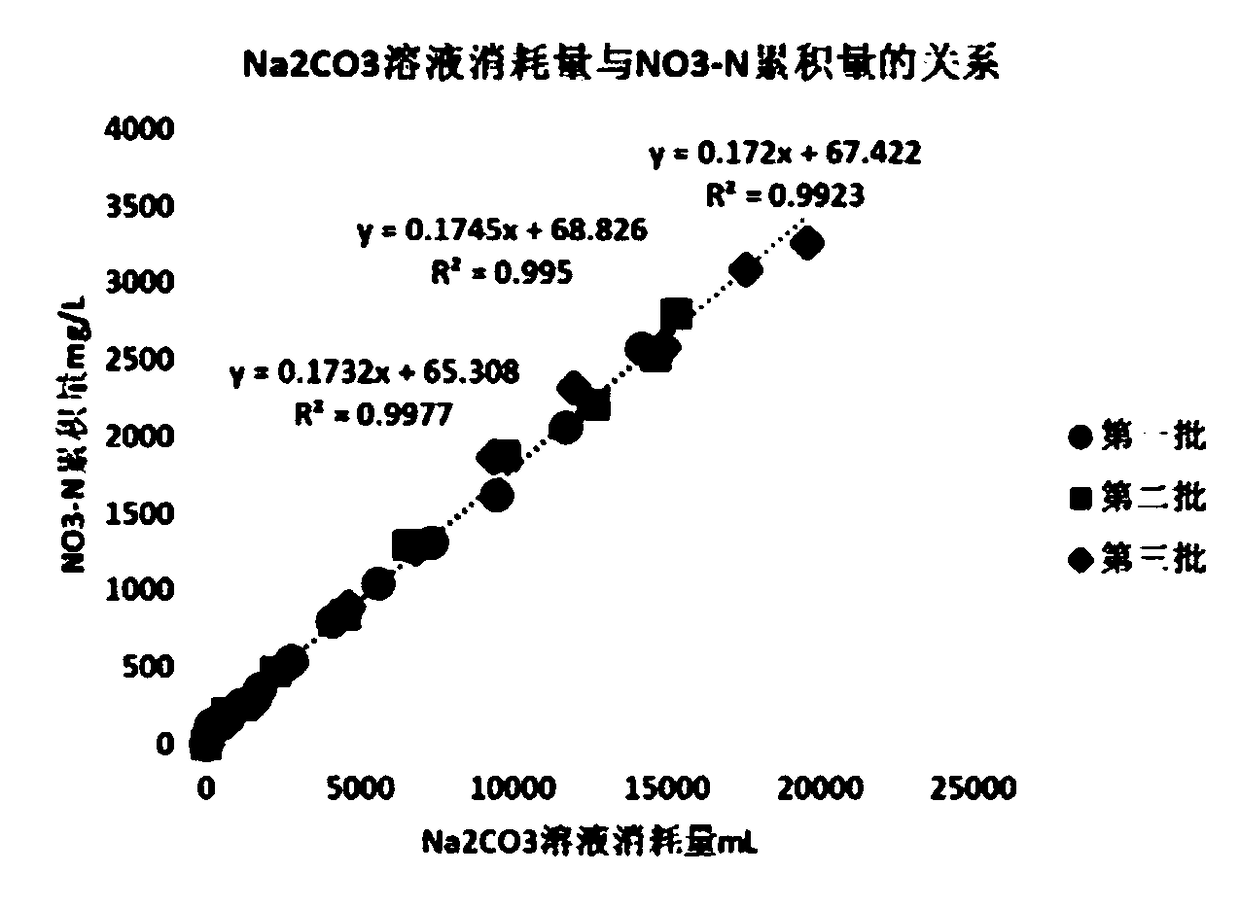

[0038] When Na 2 CO 3 When the cumulative amount X value of the solution consumption reaches V / 4 (L), the expansion is over, and the nitrification rate of the expansion solution is > 160 mg (NO 3 -N) / L / h. Stop stirring and stand still for 1 hour to collect the autotrophic nitrifying bacteria consortium, and the nitrification rate per unit mass of the harvested consortium is >600 mg (NO 3 -N) / g / h. Example 2 100L-scale automatic expansion of nitrosifying bacteria and nitrifying bacteria copolymers

[0039] The volume of the fermenter is 100L, the consortium of nitrosifying bacteria and nitrifying bacteria is used as the inoculum, the inoculum size is 1%, and the initial volume of the medium is V=80L. Stirring speed is 220r / min, keeps constant in the expansion cultivation process, and the inorganic carbon source is 10% Na 2 CO 3 solution, the inorganic nitrogen source is 20% NH 4 Cl solution. During the expansion process, the dissolved oxygen DO was controlled at 20%, and...

Embodiment 3

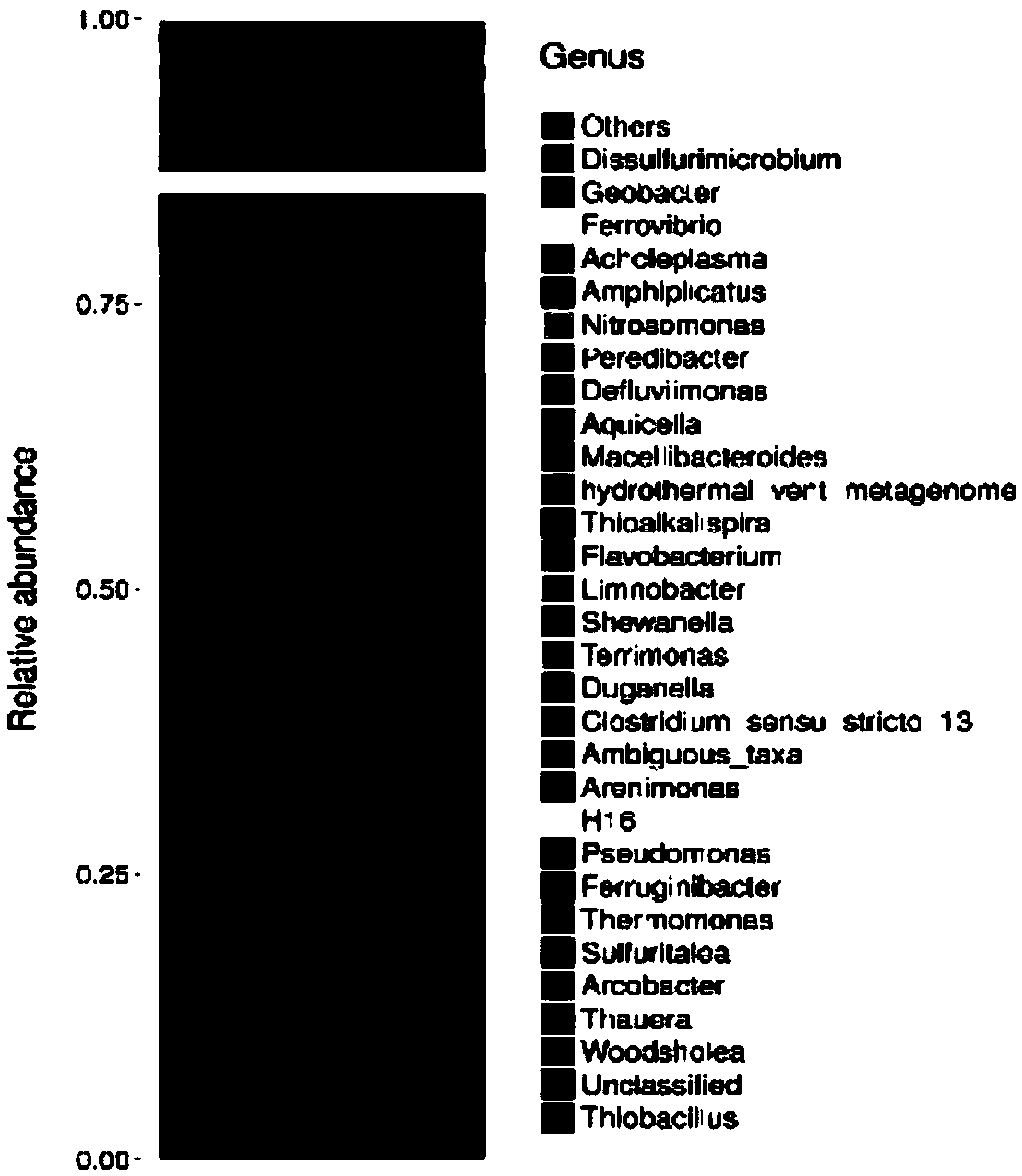

[0047] Example 3: Automatic enrichment and expansion of 100L-scale activated sludge autotrophic nitrifying bacteria flora

[0048] The volume of the fermenter is 100L, the activated sludge of the pesticide wastewater biochemical pool is used as the inoculum, the inoculum size is 10%, and the initial volume of the medium is V=80L. Stirring speed is 220r / min, keeps constant in the expansion cultivation process, and the inorganic carbon source is 10% Na 2 CO 3 solution, the inorganic nitrogen source is 20% NH 4 Cl solution. During the expansion process, the dissolved oxygen DO was controlled at 20%, and the pH was controlled at 7.50. Among them, the initial medium of autotrophic nitrifying bacteria per liter of Na in water 2 CO 3 2g-4g, MgSO 4 0.2g-0.4g, KCl 0.2g-0.4g, phosphoric acid to adjust the pH between 7.5-8.0, NH 4 Cl 0.5g-1.0g, initial NH 4 -N concentration 150mg / L-300mg / L, NO in the initial medium 3 -N concentration is controlled at 0mg / L-10mg / L.

[0049] Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com