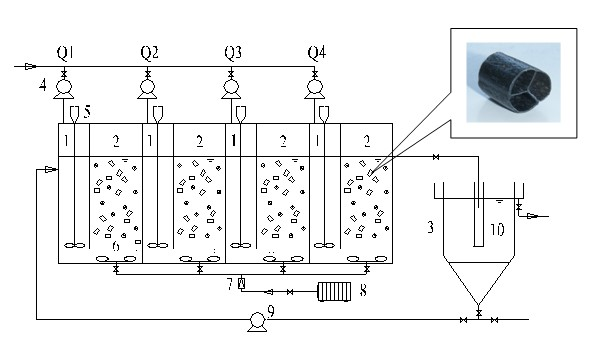

Four-stage three-phase fluidized bed step-feed deep nitrogen removal system

A technology of staged water inflow and deep denitrification, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing the volume and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation method 1: When the C / N ratio is ≤4, the ratios of water inflow in each section to the total water inflow are 9.6%, 16.2%, 27.5% and 46.7% respectively (the order is respectively the first section, the second section, the second section third and fourth paragraphs).

[0016] Specific implementation mode 2: When 4<C / N ratio≤6, the ratios of the water inflow of each section to the total water inflow are 20.4%, 23.2%, 26.4% and 30% respectively (the order is the first section and the second section respectively , third paragraph, fourth paragraph).

specific Embodiment approach 3

[0017] Specific implementation method three: when 6<C / N ratio≤8, the ratios of the water intake of each section to the total water intake are 31.5%, 26.7%, 22.6% and 19.2% respectively (the order is respectively the first section and the second section , third paragraph, fourth paragraph).

[0018] Specific implementation mode 4: When 8

specific Embodiment approach 5

[0019] Embodiment 5: When the C / N ratio > 10, the ratios of the water inflows of each section to the total water inflow are 48.6%, 27.4%, 15.6% and 8.84% respectively (the order is respectively the first section, the second section, the second section third and fourth paragraphs).

[0020]In specific implementation, materials such as polyethylene, polystyrene, and polypropylene can be used as fillers that can be suspended in water to achieve a fluidized state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com