New high-nitrogen organic sewage treatment biochemical denitrification process

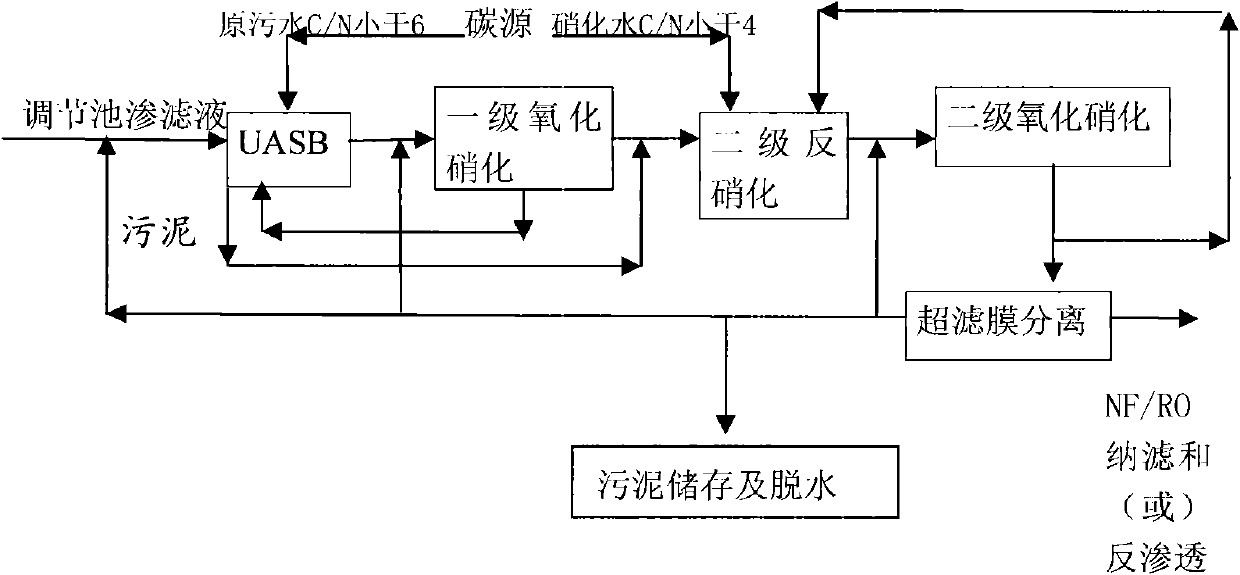

A kind of organic sewage and biochemical technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low utilization rate of carbon source, large energy consumption, high treatment cost, etc. Achieve the effect of improving carbon source utilization, saving investment and land occupation, and reducing excess sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Raw sewage, water quality: COD 1000~50000mg / l, BOD 5 200~30000mg / l, NH 3 -N 300~3500mg / l, the heavy metal concentration is within the limit that does not affect biochemistry. Entering the system of the present invention, the treated water can reach the following water quality: COD≤100mg / l, BOD 5 ≤20mg / l, TN≤40mg / l, the heavy metal concentration is within the limit of the integrated sewage discharge standard. After the following process:

[0040] 1. The qualified raw sewage enters the UASB, and at the same time, it is sent to the subsequent first oxidation and nitrification tank to return 400% to 500% of the mixed solution and part of the concentrated solution (activated sludge) of the MBR ultrafiltration membrane separation device to form the first The biological reaction conditions of anoxic after facultative oxygen, realize COD is acidified and decomposed into CO 2 , NO 2 - and NO 3 - is reduced to N by denitrifying bacteria 2 Wait for the reaction to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com