Cross-flow cooling tower

A cooling tower, cross-flow technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of reduced cooling effect, large system resistance, and high system effect value, and achieve air Minimized flow resistance, reduced separation and shedding, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

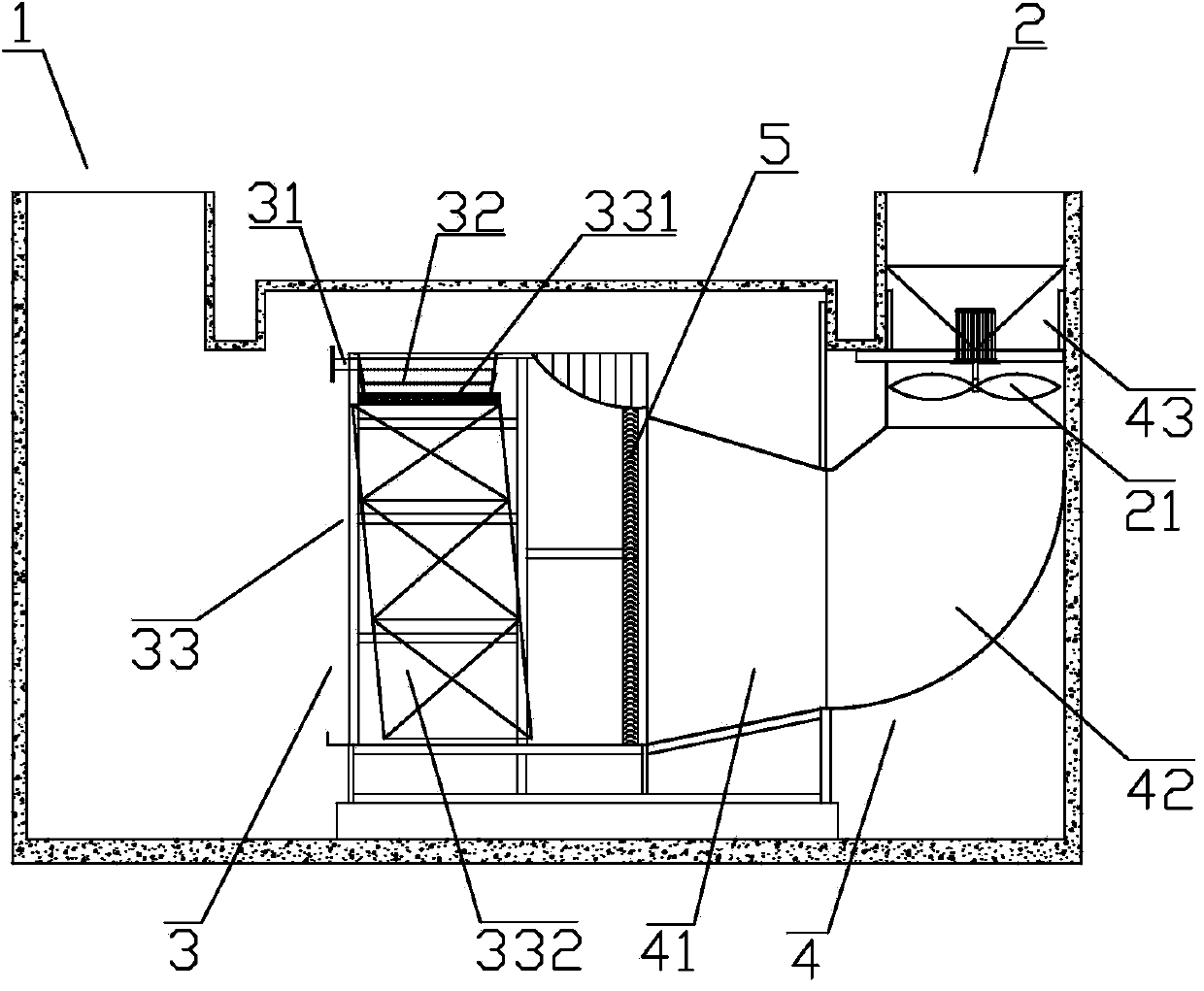

[0010] Such as figure 1 The present invention disclosed is a cross-flow cooling tower, which includes an air inlet 1 arranged at one end of the cooling tower, an air outlet 2 at the other end and a tower body 3 located in the cooling tower, and a water inlet pipe is arranged at the end of the air inlet 1 31, corresponding to the lower edge of the water inlet pipe 31, a water diffuser 32 is provided, and the lower side of the water diffuser 32 is provided with a packing device 33, and the water inlet pipe 31, the water diffuser 32 and the filler device 33 are all located in the tower body 3, and the tower One end of the body 3 is connected with a guide pipe 4, and the other end of the guide pipe 4 is connected with the air outlet 2 provided with a fan 21;

[0011] Further, the packing device 33 includes a redistribution packing 331 located on the lower side of the water distribution tray 32 and corresponding to the water distribution tray 32 and a packing 332 located on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com