Treatment method for biological nitrogen removal of reinforced sewage

A treatment method and biological technology for sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Low problems, to achieve the effect of reducing aeration volume, high controllability, and strengthening nitrification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

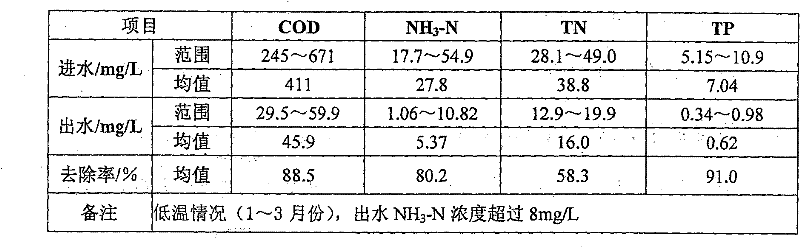

Embodiment 1

[0036] Example 1: When the carbon source is relatively sufficient and the water temperature is high, operate in the A-AAO mode. 30% of the sewage treated by fine screens, grit chambers and other facilities and the return sludge enter ① the return sludge denitrification unit, and the outflow of the return sludge denitrification unit and 70% of the sewage enter the ② anaerobic unit. The outflow of the oxygen unit and the reflux mixture of the aerobic unit enter into ③ the anoxic composite unit of activated sludge and biofilm, and the anoxic composite unit is added with 20% artificial suspension filler, and interception devices such as interception nets are installed at the outflow . The outflow of the anoxic unit enters ④ the transition unit of activated sludge, and the outflow of the transition unit enters ⑤ the aerobic composite unit of activated sludge and biofilm or embedded bacteria, and the aerobic composite unit is added with 20% artificial suspended filler , and its out...

Embodiment 2

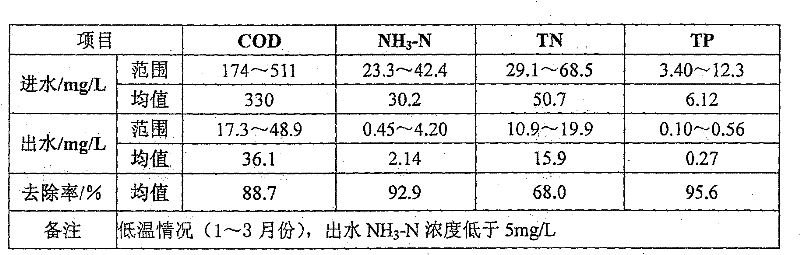

[0037] Example 2: When the carbon source is relatively sufficient and the water temperature is not high, operate in A-AAO mode. 10% of the sewage treated by fine screens, grit chambers and other facilities and the return sludge enter the ① return sludge denitrification unit, and the outflow of the return sludge denitrification unit and 90% of the sewage enter the ② anaerobic unit. The outflow of the oxygen unit and the reflux mixture of the aerobic unit enter into ③ the anoxic composite unit of activated sludge and biofilm, and the anoxic composite unit is added with 40% artificial suspended filler, and interception devices such as interception nets are installed at the outflow . The outflow of the anoxic compound unit enters into the transition unit of ④ activated sludge, and the outflow of the transition unit enters into the aerobic compound unit of ⑤ activated sludge and biofilm. The aerobic compound unit adds 45% artificial suspended filler and its output The flow is equi...

Embodiment 3

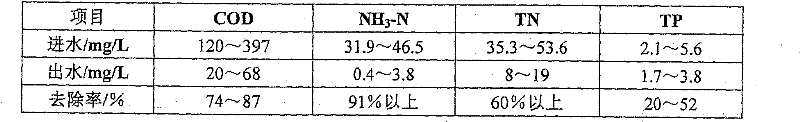

[0038] Example 3: When the carbon source is insufficient, operate in the denitrification AO mode. Sewage treated by fine screens, grit chambers and other facilities, return sludge from secondary settling tanks, and return mixed liquor from aerobic units enter ① return sludge denitrification unit, and then flow through ② anaerobic unit, ③ activated sludge Anoxic unit combined with biofilm and ④ transition unit. Add 20% to 40% of artificial suspended filler to the anoxic unit, and install intercepting devices such as intercepting nets at the outflow. According to the influent carbon source and the carbon source required for denitrification, etc., carbon source methanol and / or acetate can be added to the inflow end of the return sludge denitrification unit. The transition unit can adopt the composite process of activated sludge and biofilm, or the activated sludge process. If the composite process is adopted, 10% to 50% of artificial suspended filler should be added, and interce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com