Preparation method of high-activity nitrifying bacteria biological membrane for aquaculture water treatment

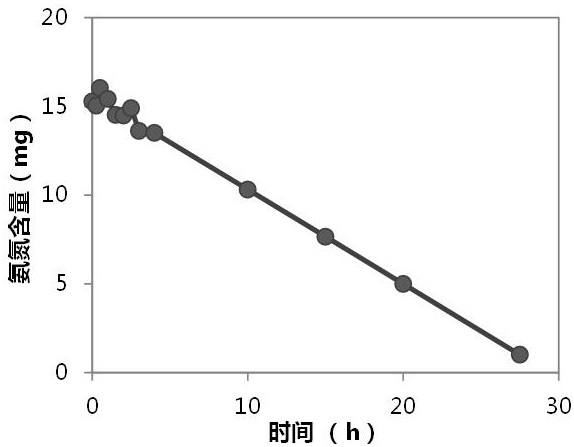

An aquaculture, nitrifying bacteria technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, seawater treatment and other directions, can solve the problem of low ammonia nitrogen removal rate, improve nitrification activity, speed up preparation speed, promote effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the nitrifying bacteria biofilm of the present invention specifically includes the following steps.

[0034] (1) Load the mixture of seaside fine sand and aquaculture pond water into the reactor, and the volume of sea sand is 1 / 3 of the volume (mixture) of the reactor.

[0035] (2) Add 300-500 mg of MgSO to every 1000 mL of distilled water 4 ·H 2 O, 20~50mg of CaCl 2 ·H 2 O, 0.2~2.0mg of MnCl 2 ·H 2 O, 0.1 to 0.2 mg of Na 2 MoO 4 ·H 2 O, 0.1~0.2mg CoCl 2 ·H 2 O, 0.1~0.2mg of ZnSO 4 ·H 2 O and 80 to 500 mg of K 2 HPO 4 , mixed evenly, and configured into a nutrient solution.

[0036] Add 1-2% nutrient solution to the reactor mixture to form a mixed solution together with the mixture.

[0037] Elements such as Mg, Ca, Mn, Na, Co, Zn and K, especially Mn, Co and Zn, are necessary trace elements for some efficient nitrifying bacteria species, which can avoid being disadvantaged due to the lack of these trace elements. competitive p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com