Artificial oxygenation type composite underflow wet land sewage purification process

A technology of artificial wetland and vertical flow wetland, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Thoroughly wait for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

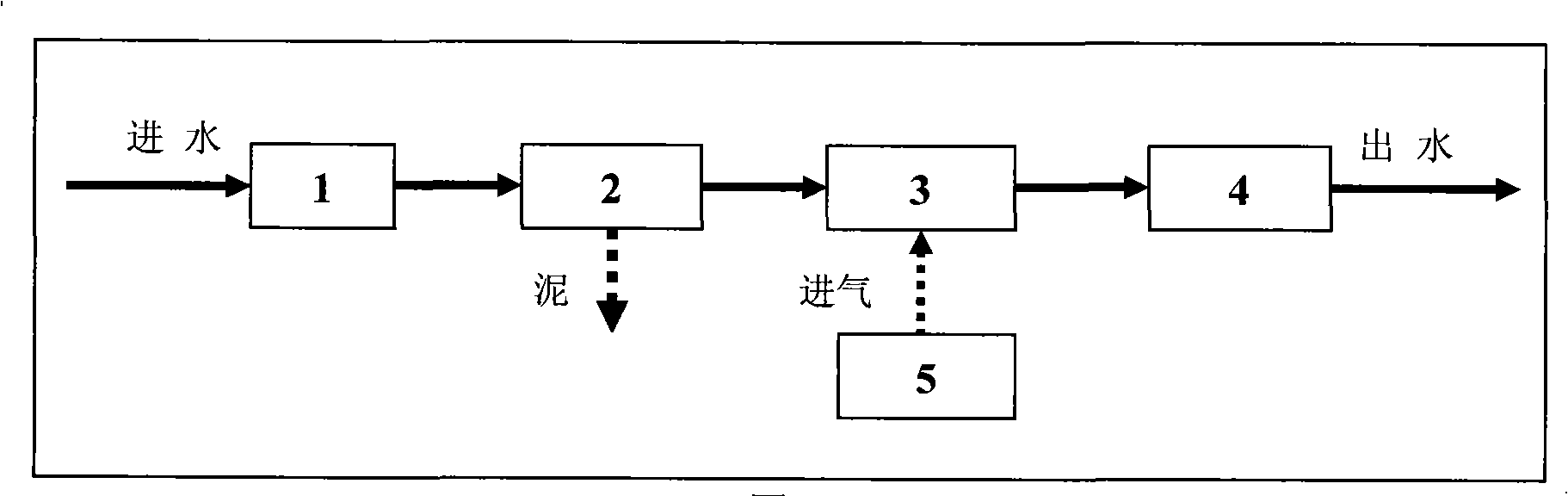

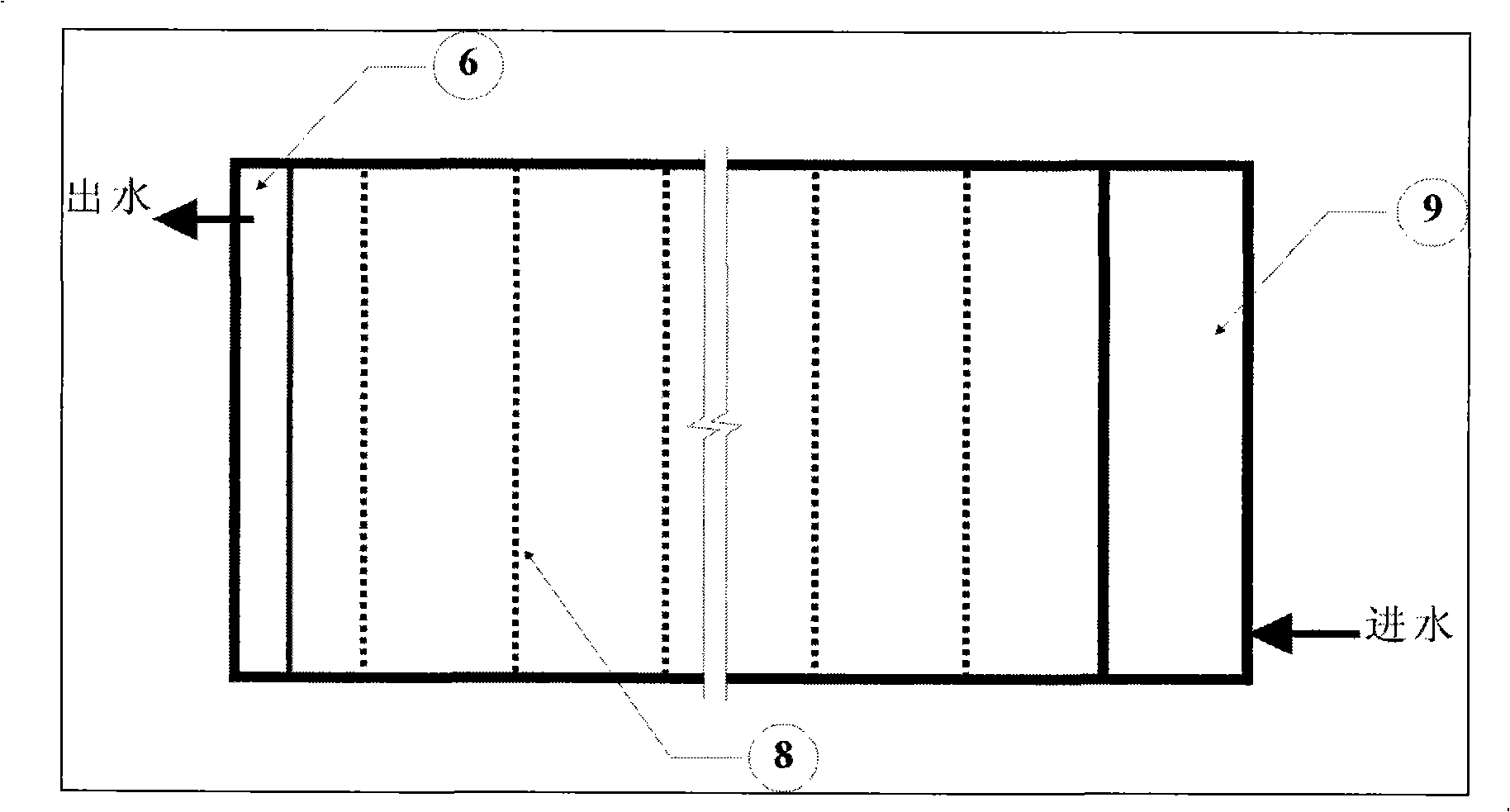

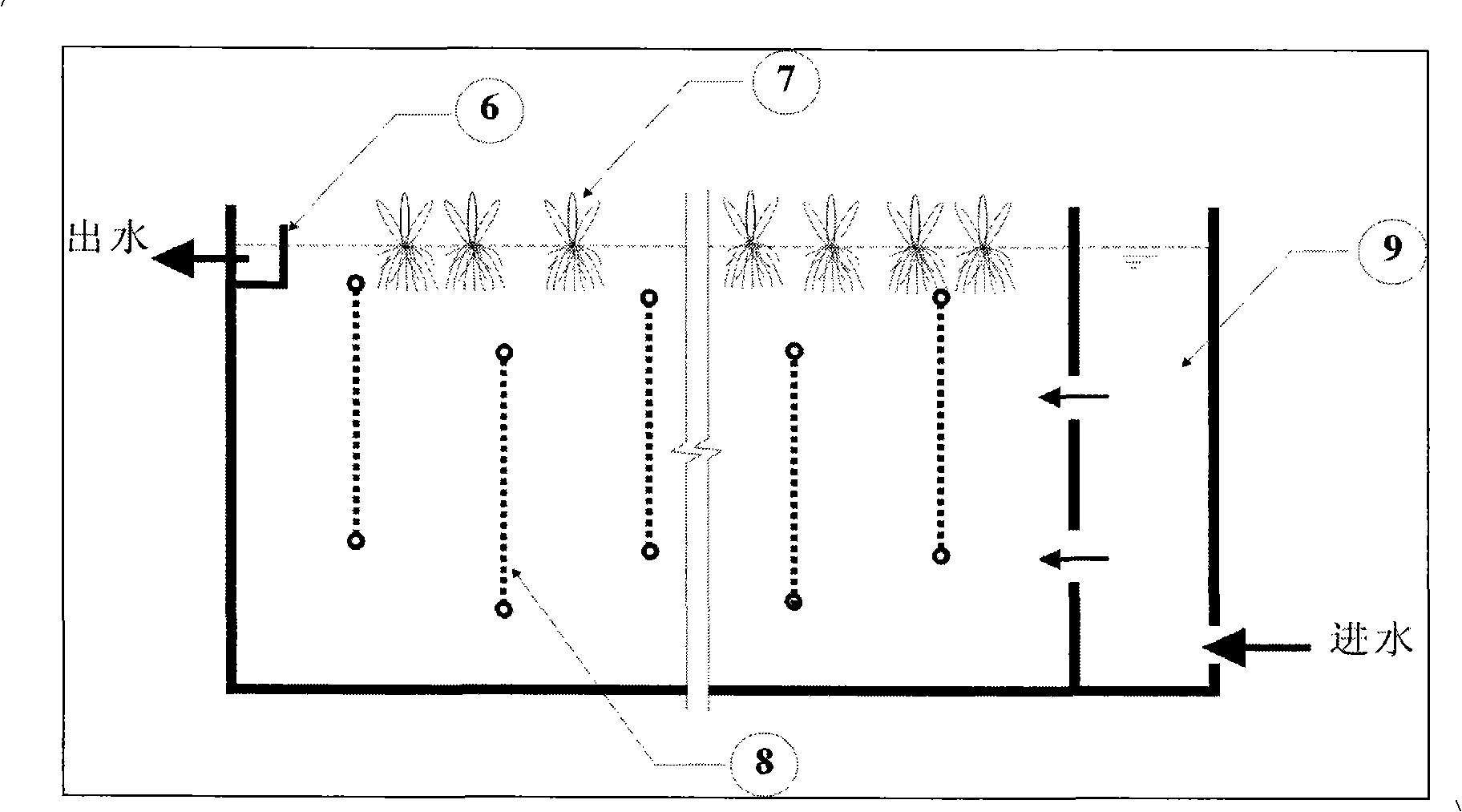

[0010] according to figure 1 As shown in the process flow, the influent water first passes through the grille (Fig. 1) to intercept and remove floating garbage and sundries, then enters the biologically enhanced sedimentation tank (Fig. 2), passes through the filter screen (Fig. 8) and floating plants (Fig. 7) Most of the suspended particles have been effectively removed, and then collected into the water distribution ditch (Fig. 14) of the micro-aeration vertical flow wetland through the outlet weir (Fig. 6), and evenly distributed by the water distribution pipe at the bottom of the wetland. It flows into the wetland from bottom to top, and at the same time, the high-pressure blower aerates and oxygenates the wetland system through the aeration pipe (Fig. 12) arranged in the water inlet pipe to improve the oxidation decomposition and nitrification effect of organic matter, and the micro-aeration vertically flows the wetland water through the weir After collection, it enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com