Combined drop-driven biological rotating disk reactor

A biological turntable and reactor technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of affecting the sewage treatment efficiency of the biological turntable, reducing oxygenation efficiency, and large rotational resistance, etc. Achieve the effects of eliminating resistance, increasing oxygenation rate, and reducing driving resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

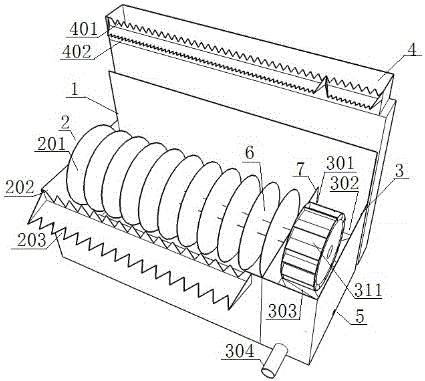

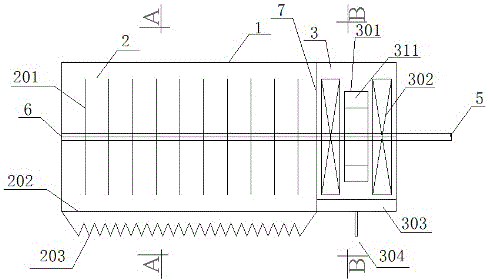

[0021] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

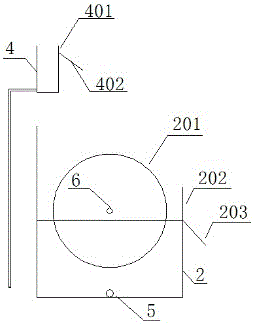

[0022] Such as Figure 1~Figure 4 As shown, the combined drop water driven biological turntable reactor of the present invention includes a tank body 1 , a high-level water distribution tank 4 arranged above the tank body 1 , and a mud discharge pipe 5 arranged at the bottom of the tank body 1 . The pool body 1 is divided into a turntable area 2 and a driving area 3, separated by a partition 7 in the middle. The rotating shaft 6 traverses the turntable area 2 and the driving area 3, and is fixed on the side wall of the pool body 1. The mud discharge pipe 5 crosses the turntable area 2 and the driving area 3 and is placed at the bottom of the pool. The high-level water distribution tank 4 includes an outlet triangular weir 401 and a diversion dispersion plate 402, such as Figure 5 shown.

[0023] The turntable area 2 includes a turntable 201 , the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com