Technological method for treating coking wastewater

A technology of coking wastewater and process methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that COD is difficult to be effectively removed, affects the denitrification effect of the system, and increases the number of structures Volume and other issues, to achieve the effect of improving nitrification performance and load resistance, high treatment efficiency, and prolonging the sludge age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

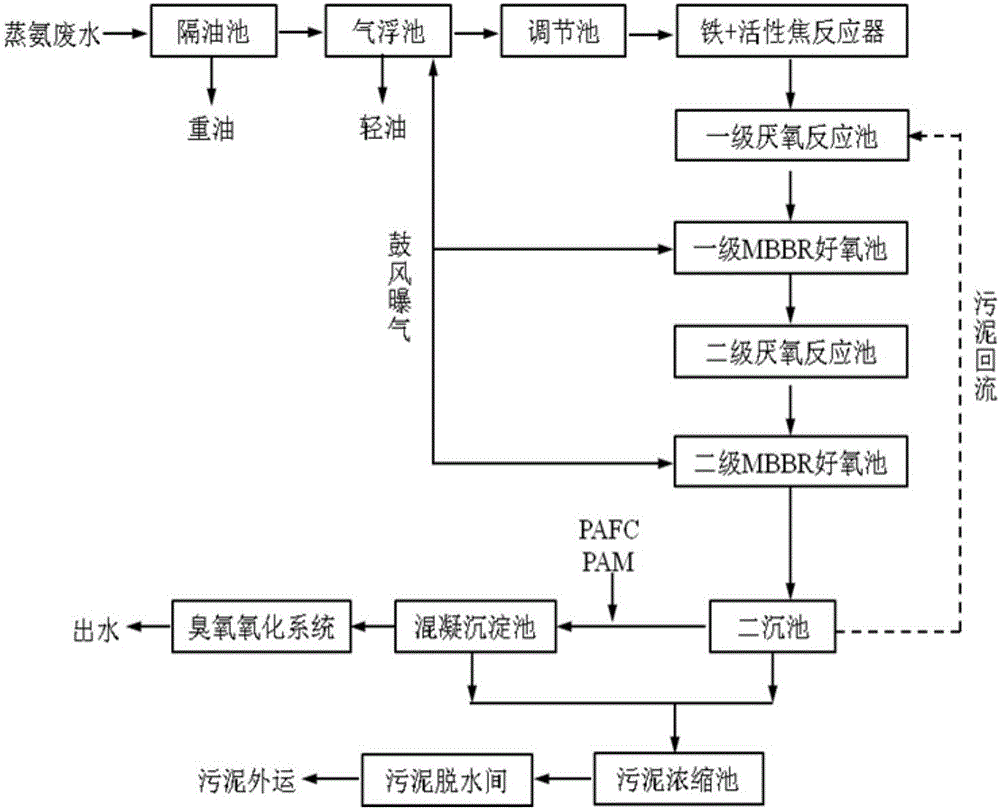

[0027] The present embodiment is a kind of processing method of coking waste water, and this processing method comprises the following steps:

[0028] (1) The coking wastewater is subjected to ammonia distillation treatment and then enters the grease trap and the air flotation tank for oil-water separation;

[0029] (2) The coking wastewater after oil-water separation enters the regulating tank for water quality regulation;

[0030] (3) After the water quality is adjusted, the coking wastewater enters the iron+activated coke reactor to carry out the iron-carbon micro-electrolysis reaction and absorb the suspended particles in the coking wastewater;

[0031] (4) Enter the coking waste water flowing out of the iron+activated coke reactor into the biochemical treatment system for biological denitrification and removal of organic pollutants;

[0032] (5) Enter the coking wastewater after biochemical treatment into the secondary sedimentation tank and the coagulation sedimentation...

Embodiment 2

[0041] Based on the above embodiment, this embodiment has a preparatory process before step 3: mix the activated coke sintered at high temperature and crushed with iron filings or iron slag as filler, and set the filler in the iron + activated coke reaction device, wherein the particle size of the active coke is 1-4 cm, and the aeration treatment is carried out;

[0042] Aeration is carried out in the iron + activated coke reactor, on the one hand, Fe 2+ Fe produced by oxidation 3+ Gradually hydrolyzed to form Fe(OH) with a high degree of polymerization 3 Colloidal flocculants can effectively absorb and condense pollutants in water, thereby enhancing the purification effect of wastewater. On the other hand, after the micro-electrolysis reaction, the refractory organics can open rings and break chains to form simple organics that can be utilized by microorganisms. Iron + activated coke (carbon) can consume a large amount of hydrogen ions through the aeration reaction, which ...

Embodiment 3

[0045] Based on above-mentioned embodiment, when the biological denitrification of described step (4) and the removal treatment of organic pollutant, in described one-level MBBR aerobic pond and secondary MBBR aerobic pond, add mobile suspension carrier; The amount of the mobile suspension carrier is 30% to 50% of the pool capacity of the first-level MBBR aerobic pool, and 20% to 30% of the pool capacity of the second-level MBBR aerobic pool. The specific gravity of the carrier is 0.97-0.98kg / m 3 , the porosity is over 90%, and the specific surface area is over 500m 2 / m 3 ; And carry out aeration treatment.

[0046] In this example, more nitrosating bacteria are enriched by adding mobile suspension fillers, and short-range nitrification is realized by controlling parameters such as pH value, dissolved oxygen, and temperature. It can not only shorten the nitrification process and reduce the construction cost of structures, but also reduce aeration energy consumption and save...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com