Method and system for recycling positive poles from waste lithium batteries and carrying out regeneration and repair

A technology for waste lithium batteries and ternary lithium batteries, which is applied in battery recycling, recycling by waste collectors, recycling technology, etc. It can solve the problems of poor material stability and consistency, bacterial culture, harsh use conditions, and restrict technology applications. Promotion and other issues to achieve the effect of mild and controllable heat treatment process, excellent capacity retention rate, and advanced stripping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

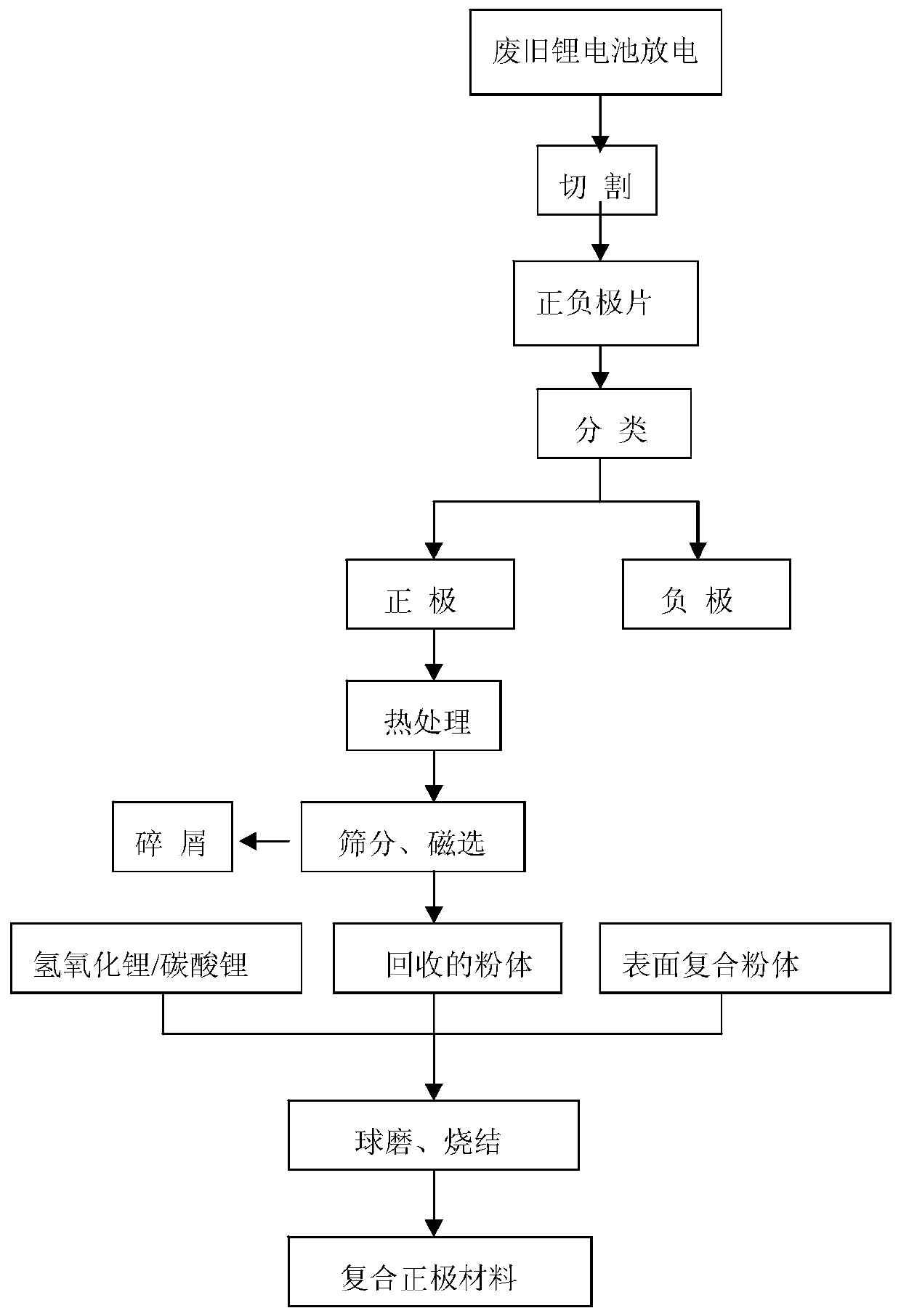

Embodiment 1

[0079]A certain type of waste ternary lithium battery is used as raw material. First discharge the used batteries, remove the shell, cut the ends in a closed protective atmosphere, extract the pole pieces and diaphragm, and clean the electrolyte and electrolyte in the cleaning tank, and the air-dried pole pieces are sorted, cut and classified into positive , Negative plate and diaphragm. The negative plate is soaked in water to dissolve the binder, filtered and dried to recover the primary copper foil and carbon powder. Weigh 500g of the sorted positive electrode and treat it in a muffle furnace at 650°C for 5 minutes, then remove the binder, quench the water from 650°C to 30°C instantly, and process it in ultrasonic vibration for 30 minutes to peel off the positive electrode material and aluminum foil , filtered to obtain aluminum foil and black powder, and then dried at 50°C. The aluminum foil is separated by screening, and the aluminum foil can be directly used for alumin...

Embodiment 2

[0082] A certain type of waste ternary lithium battery is used as raw material. First discharge the used batteries, remove the shell, cut the ends in a closed protective atmosphere, extract the pole pieces and diaphragm, and clean the electrolyte and electrolyte in the cleaning tank, and the air-dried pole pieces are sorted, cut and classified into positive , Negative plate and diaphragm. The negative plate is soaked in water to dissolve the binder, filtered and dried to recover the primary copper foil and carbon powder. Weigh 1,200g of the sorted positive electrode and treat it in a muffle furnace at 450°C for 360min, then remove the binder, quench the water from 550°C to 20°C instantly, and process it in ultrasonic vibration for 20min to peel off the positive electrode material and aluminum foil , filtered to obtain aluminum foil and black powder, and then dried at 80°C. The aluminum foil is separated by screening, and the aluminum foil can be directly used for aluminum sm...

Embodiment 3

[0084] A certain type of waste ternary lithium battery is used as raw material. First discharge the used batteries, remove the shell, cut the ends in a closed protective atmosphere, extract the pole pieces and diaphragm, and clean the electrolyte and electrolyte in the cleaning tank, and the air-dried pole pieces are sorted, cut and classified into positive , Negative plate and diaphragm. The negative plate is soaked in water to dissolve the binder, filtered and dried to recover the primary copper foil and carbon powder. Weigh 800g of the sorted positive electrode and treat it in a muffle furnace at 550°C for 30 minutes, then remove the binder, and quench the water from 450°C to 10°C instantly, and process it in ultrasonic vibration for 30 minutes to peel off the positive electrode material and aluminum foil , filtered to obtain aluminum foil and black powder, and then dried at 60°C. The aluminum foil is separated by screening, and the aluminum foil can be directly used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com