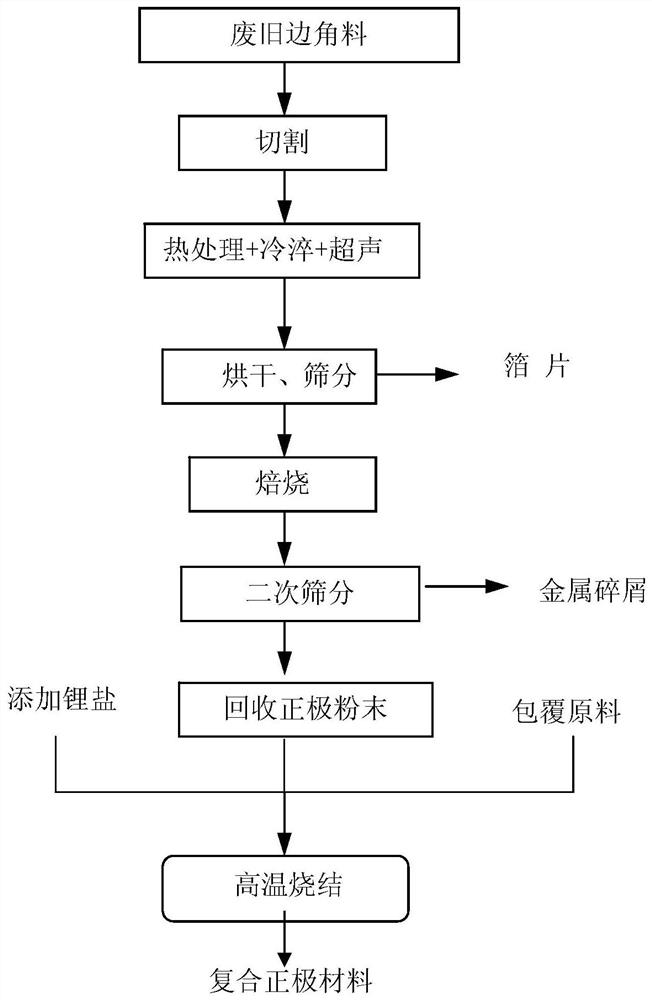

Method and system for recycling and preparing composite positive electrode materials from leftover waste and defective products

A technology of composite cathode material and corner waste, applied in the field of lithium battery recycling, can solve the problems of poor material stability and consistency, bacterial culture, harsh use conditions, and powder that cannot be directly reused, and achieves a mild heat treatment process. Controllable, eliminate secondary environmental pollution, excellent capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

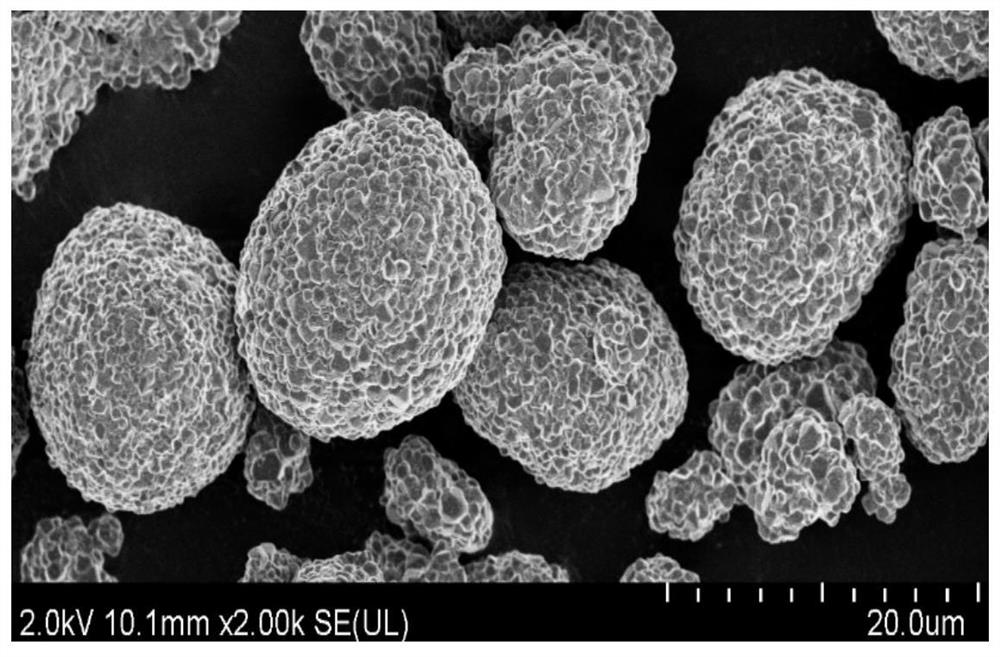

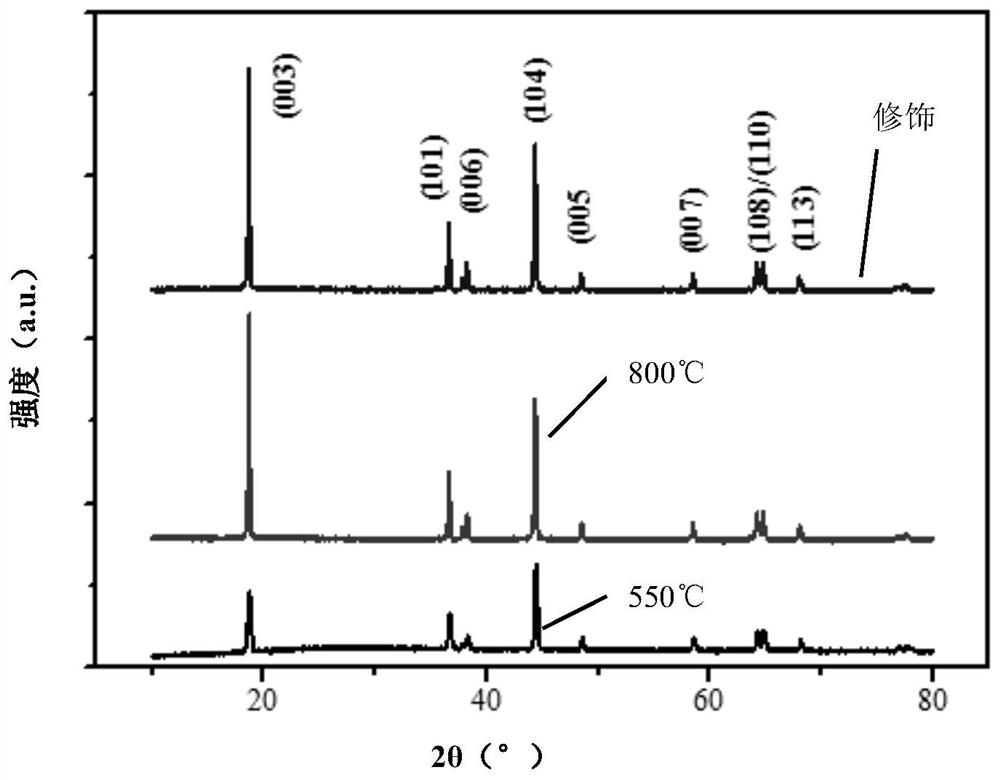

[0075] A certain type of waste ternary lithium battery scraps are used as raw materials. Firstly, cut the waste scraps into 0.5x0.5cm chips of 2kg, put them into the pyrolysis kiln and heat them at 650°C for 10 minutes, take them out while they are still hot, and directly add them to ice water to cool them down from 650°C to 30°C instantly. Ultrasonic vibration treatment was performed for 20 minutes to peel off the positive electrode material and the aluminum foil, and the aluminum foil and black powder were filtered with a large-pore sieve to obtain an aluminum foil with a smooth surface. The black powder is filtered to remove moisture, dried at 50° C., and then sieved for a second time to filter out metal debris; a carbon-containing positive electrode powder is obtained. The carbon-containing powder is fired in an air atmosphere at a temperature of 850°C for 0.5h. Sampling and weighing, adding excess 5% and 8% lithium salt and titanium dioxide respectively, ball milling and...

Embodiment 2

[0078]A certain type of waste ternary lithium battery scraps are used as raw materials. Firstly, cut the waste scraps into 0.2x0.2cm scraps of 1.2kg, put them into the pyrolysis furnace and heat them at 400°C for 6 hours, then take them out while they are hot and add them to ice water to cool them down instantly from 550°C to 20°C. At the same time, the ultrasonic vibration treatment was performed for 15 minutes to peel off the positive electrode material and the aluminum foil, and the aluminum foil and the black powder were filtered with a large-pore sieve to obtain an aluminum foil with a smooth surface. The black powder is filtered to remove moisture, dried at 80° C., and then sieved for a second time to filter out metal debris; a carbon-containing positive electrode powder is obtained. The carbon-containing powder is fired in an air atmosphere at a temperature of 700°C for 10 hours. Sampling and weighing, adding an excess of 8% lithium salt and silicon dioxide, ball milli...

Embodiment 3

[0081] A certain type of waste ternary lithium battery scraps are used as raw materials. Firstly, cut the waste scraps into 0.5x0.5cm scraps of 2.5kg, put them into the pyrolysis furnace and heat-treat at 650°C for 1min, then take them out while they are still hot and directly add them to ice water to cool them down from 450°C to 10°C instantly. At the same time, the ultrasonic vibration treatment was performed for 20 minutes to peel off the positive electrode material and the aluminum foil, and the aluminum foil and the black powder were filtered with a large-pore sieve to obtain an aluminum foil with a smooth surface. The black powder is filtered to remove moisture, dried at 60° C., and then sieved for a second time to filter out metal debris; a carbon-containing positive electrode powder is obtained. The carbon-containing powder is fired in an oxygen-enriched atmosphere at a temperature of 750°C for 2 hours. Sampling and weighing, adding an excess of 3% lithium salt and yt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com