Food pretreatment equipment and automatic catering continuous cooking system

A pretreatment and food technology, which is applied in food forming, food coating, food science, etc., can solve the problems of limited application effect, large oil input, and poor coordination in the field of fast food cooking, so as to improve accuracy and production efficiency , strong applicability and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

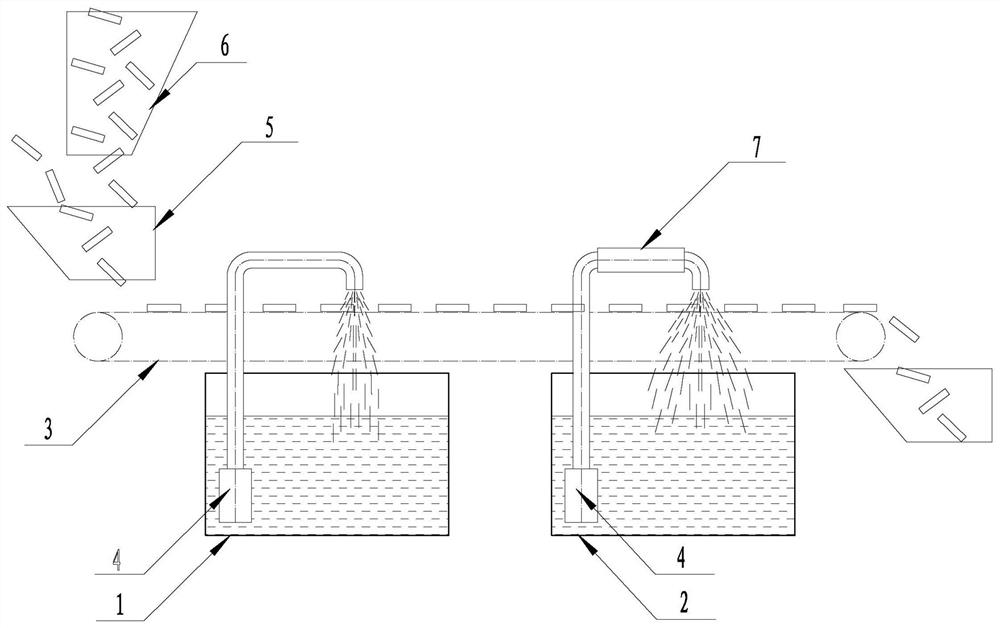

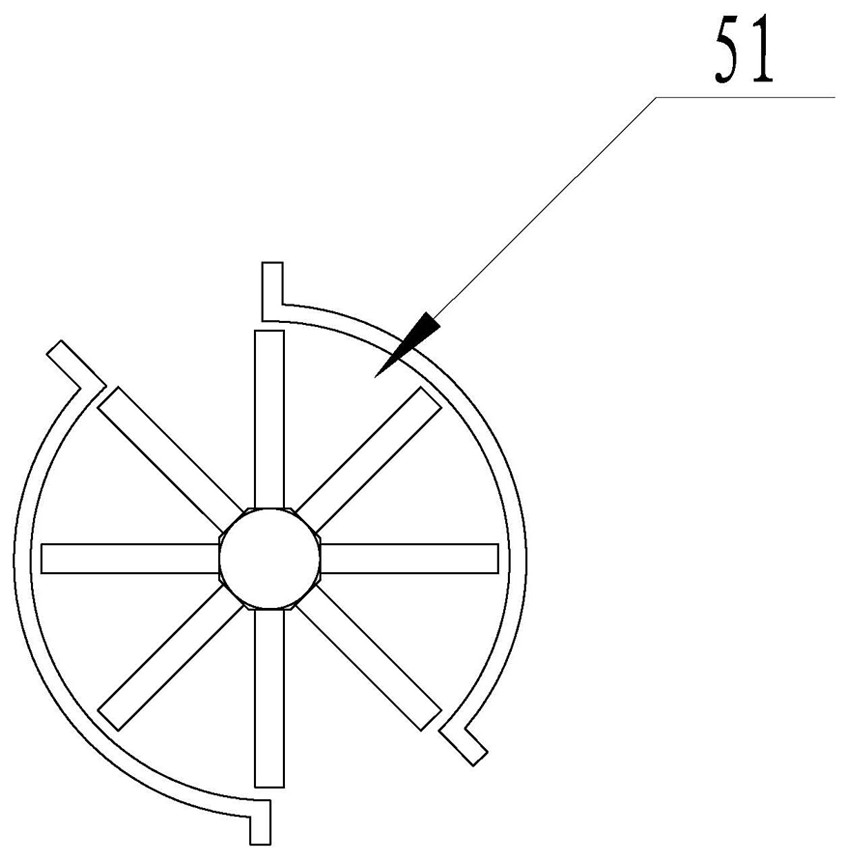

[0037] like Figure 1 to Figure 2 As shown, this embodiment provides a food pretreatment equipment, which can perform automatic battering and oil pretreatment on food materials. It includes a batter storage unit 1, a hot oil storage unit 2, an extraction device 4, and a first metal mesh conveyor belt 3 located above the batter storage unit 1 and the hot oil storage unit 2, and the first metal mesh conveyor belt 3 is driven by a servo motor.

[0038] The batter storage unit 1 and the hot oil storage unit 2 are sequentially arranged from the upstream to the downstream of the process, and the first metal mesh conveyor belt 3 is suspended above the batter storage unit 1 and the hot oil storage unit 2 . The upper parts of the batter storage unit 1 and the hot oil storage unit 2 are respectively provided with openings for receiving batter and hot oil seeping down from the first metal mesh conveyor belt 3 . Both the batter storage unit 1 and the hot oil storage unit 2 are provided w...

Embodiment 2

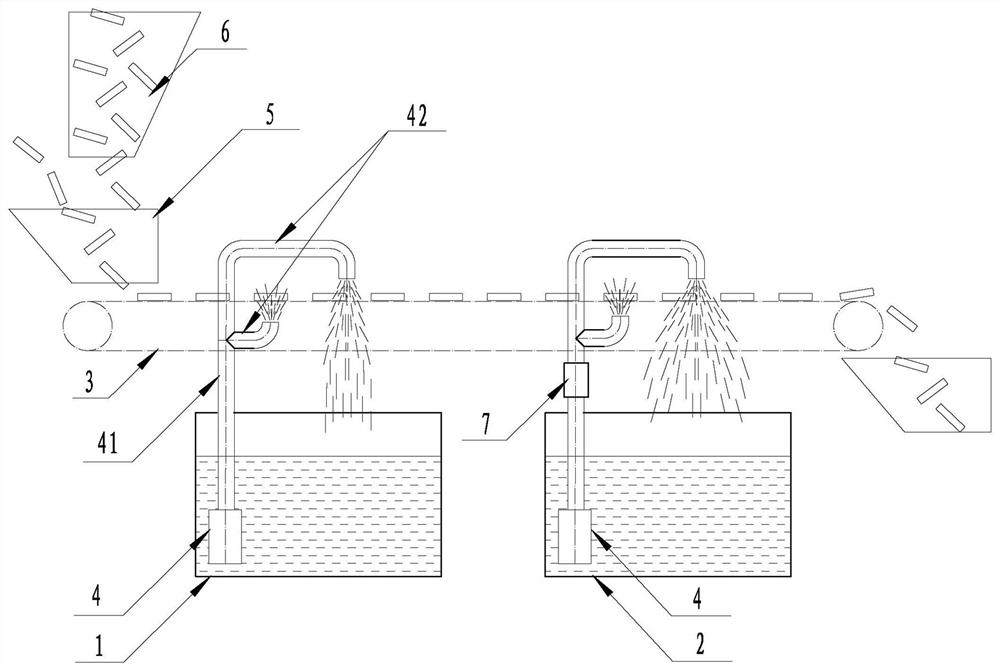

[0049] like image 3 As shown, the present embodiment provides a kind of food pretreatment equipment, and the difference from the first embodiment is that the extraction device 4 transports the batter and hot oil to the top and the upper working surface of the first metal mesh conveyor belt 3 respectively through pipelines. Specify the location below.

[0050] Specifically, the conveying main pipe 41 communicates with two transverse conveying branch pipes 42, and the two conveying branch pipes 42 are respectively located above and below the upper working surface of the first metal mesh conveyor belt 3, and the conveying branch pipes 42 are provided with a plurality of spray heads , the spray head is directed toward the food material on the first metal mesh conveyor belt 3, and then the batter and hot oil can be sprayed onto the food material simultaneously from top to bottom. The fast-flowing batter and oil can fully contact with the food, and the batter and oil can be quickl...

Embodiment 3

[0053] like Figure 4 to Figure 6 As shown, the present embodiment provides a food pretreatment device, which can perform automatic blanching, battering and oil pretreatment on food materials. The difference between this embodiment and Embodiment 1 or Embodiment 2 is that: the food pretreatment equipment of this embodiment has an automatic blanching function, and an anti-sticking device is provided at the same time.

[0054] A hot water storage unit 8 and a second metal mesh conveyor belt 9 erected directly above the hot water storage unit 8 are installed at the upstream process position of the batter storage unit 1 . The hot water storage unit 8 is also provided with an extraction device 4, which is used to transport hot water to a designated position above the second metal mesh conveyor belt 9 through pipelines, and to blanch the food materials on the second metal mesh conveyor belt 9. Processing, the blanched food material is transported from the tail end of the second met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com