Dust collector dust-collecting device with water spray device

A technology of water spray device and dust collection device, which is applied in the direction of suction filter, etc., which can solve the problems of affecting the cleaning effect, motor life, not easy to pour out, and polluting the environment, so as to increase the quality, prevent dust from flying, and reduce dust emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment, the vacuum cleaner dust collection device that the present invention has water spray device is described in detail:

[0043] In the drawings of the present invention, the same symbols are used for the same parts as those of the prior art.

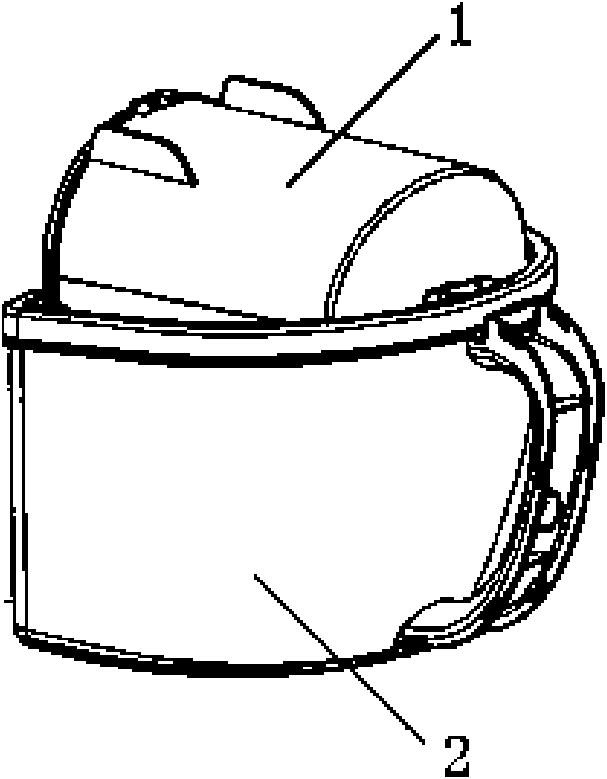

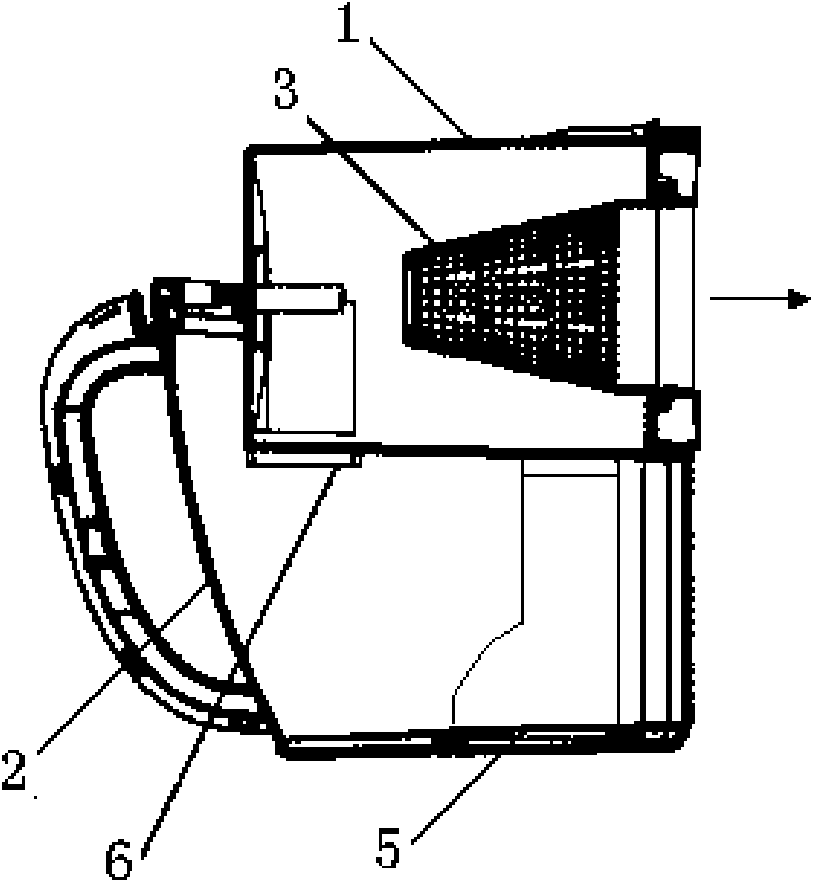

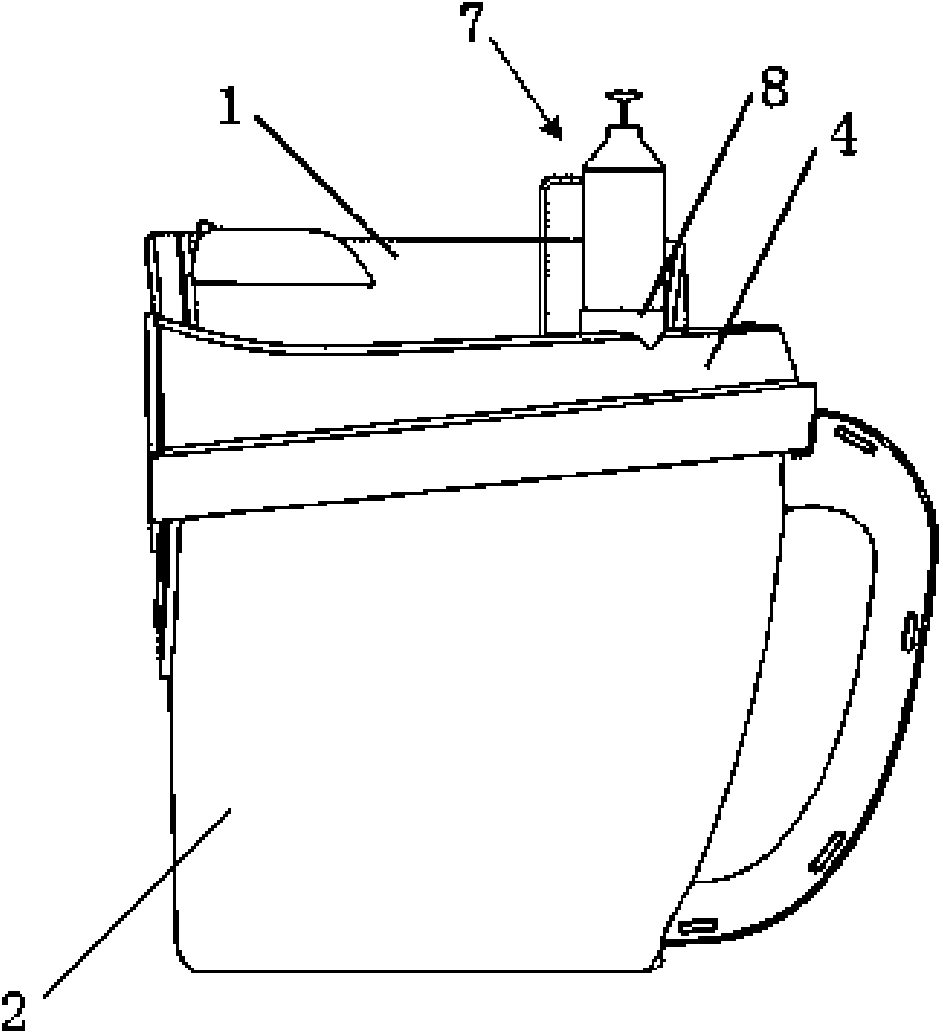

[0044] image 3 It is the front view of the dust collecting device of the vacuum cleaner with the water spray device of the present invention. like image 3 As shown, the dust collecting device of a vacuum cleaner with a water spray device of the present invention comprises a dust collecting bucket 2, a bung 4 above the dust collecting bucket and a cyclone separator 1, and a device for spraying water into the dust collecting bucket is arranged on the dust collecting bucket. Liquid sprinkler 7 . The water spraying device is connected on the bung of the dust collecting bucket by the fixing part 8 . The fixing part 8 is integrally formed with the bucket cover 4 of the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com