Fixed tail speed reduction device

A terminal velocity and deceleration parachute technology, which is applied in the field of constant velocity deceleration devices and fixed terminal velocity deceleration devices, can solve the problems of low parachute terminal velocity, reduced penetration capability of body detonation warheads, and failure to meet actual combat needs, so as to achieve guaranteed The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

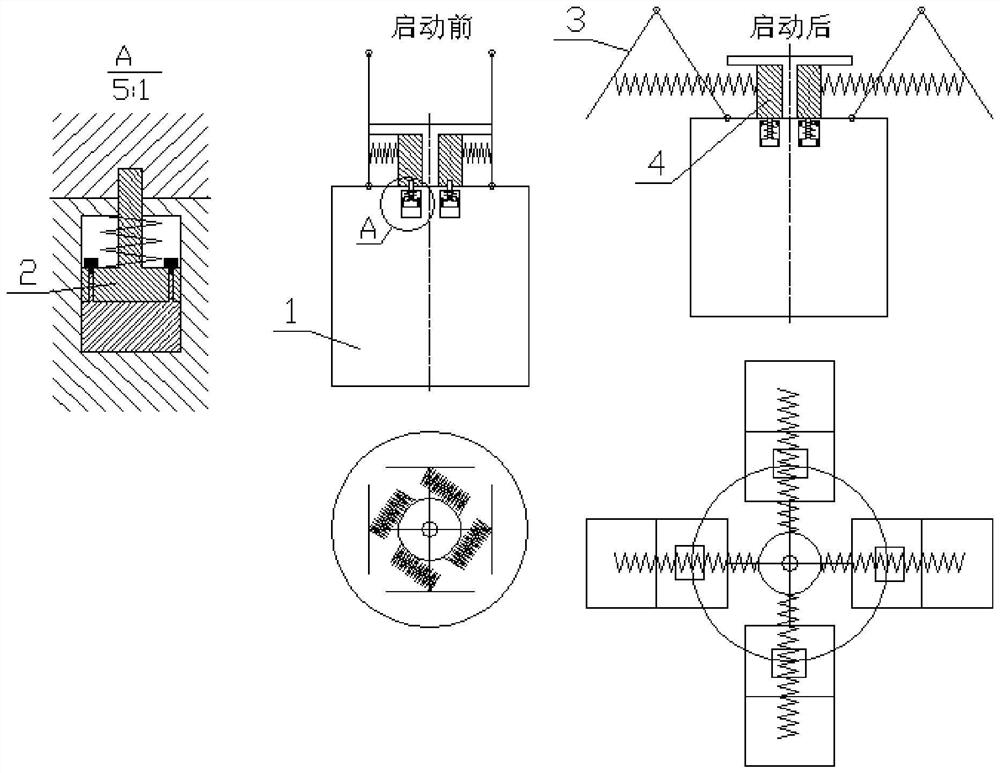

[0031] Such as figure 1 As shown, the present embodiment provides a fixed-end speed reduction device, which includes a body detonation warhead shell 1, which is filled with high-energy fuel inside the body detonation warhead shell 1, and also includes a timing start positioning pin 2, a fixed-end Speed deceleration parachute 3, rotating energy storage device 4, wherein:

[0032] The shape of the body detonation warhead casing 1 is a first cylinder, and the first cylinder is a body of revolution. The direction is the direction of motion of the body detonation warhead shell 1;

[0033] There is a first cylindrical boss in the center of the upper end surface of the first cylinder of the body detonation warhead shell 1, and the outer surface of the first cylindrical boss has four first rectangular bosses uniformly distributed in the circumferential direction. The upper end surface of the first cylinder of the body detonation warhead shell 1 has two left and right symmetrical f...

Embodiment 2

[0069] The difference between the final speed reduction device of this embodiment and that of Embodiment 1 is that the weight of the second plug is 1.6 kg. Others are all the same as in Example 1.

[0070] Process ten above-mentioned constant speed deceleration devices of the present embodiment, test according to the assembly and use method of the fixed speed deceleration device, through live ammunition launch, the speed of body detonation warhead casing 1 when approaching the target is all at 200m / s Within ±17m / s, the speed error is not more than 10%, which meets the use requirements of the body detonation warhead in actual combat, and proves that the final speed deceleration device of this embodiment is effective.

[0071] Therefore, the technical effect brought about by the final speed deceleration device given in this embodiment is embodied as follows:

[0072] The constant speed deceleration parachute starts when the shell of the body detonation warhead is close to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com