Pit digging machine for fruit tree planting

A technology for digging holes and fruit trees, which is applied in planting methods, applications, excavation/covering ditches, etc. It can solve the problems of fruit trees not absorbing fertilizer well, manual excavation, and heavy labor burden on staff, and achieve effective It is conducive to the growth of fruit tree roots, simplifies the processing steps, and is conducive to the effect of water and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

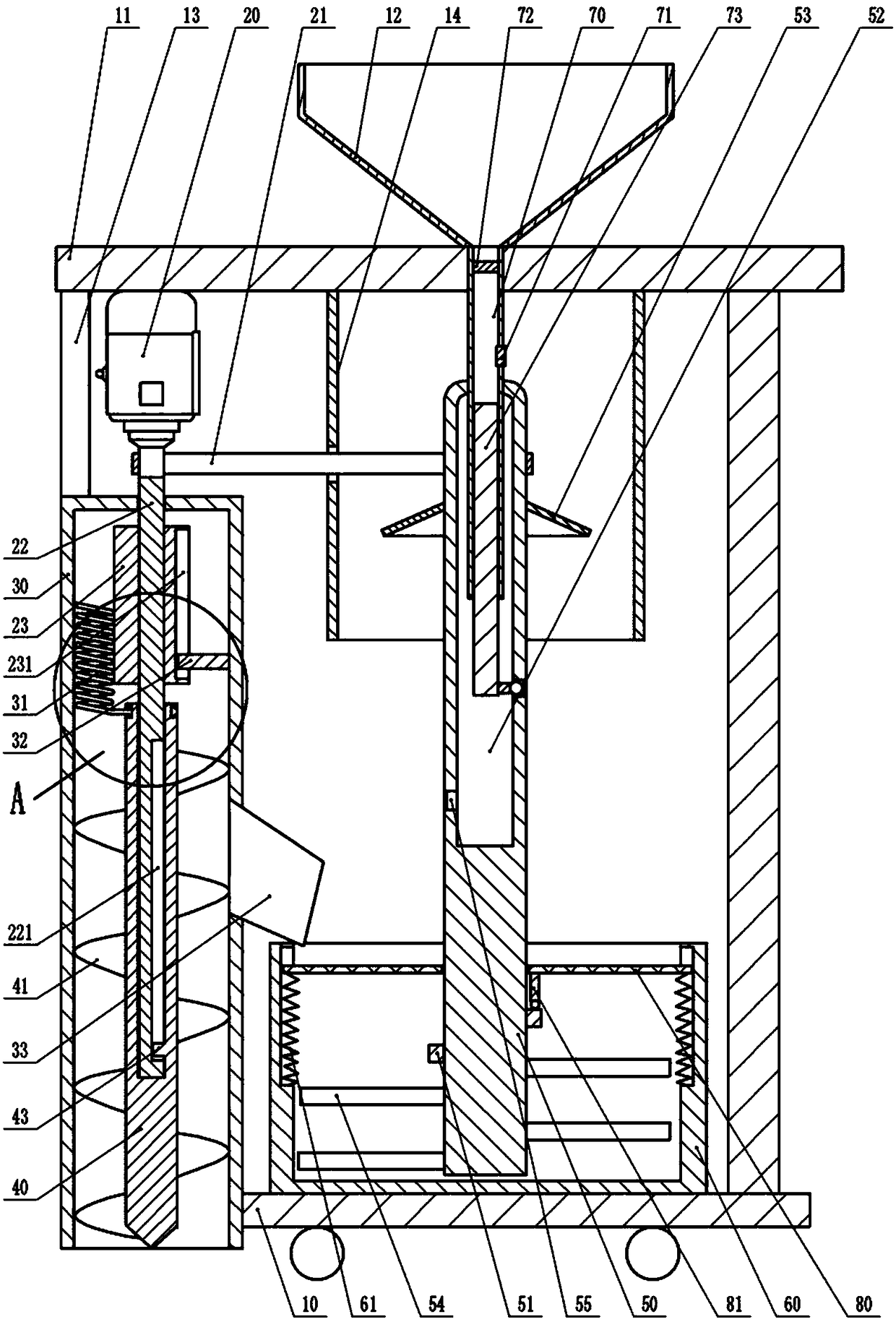

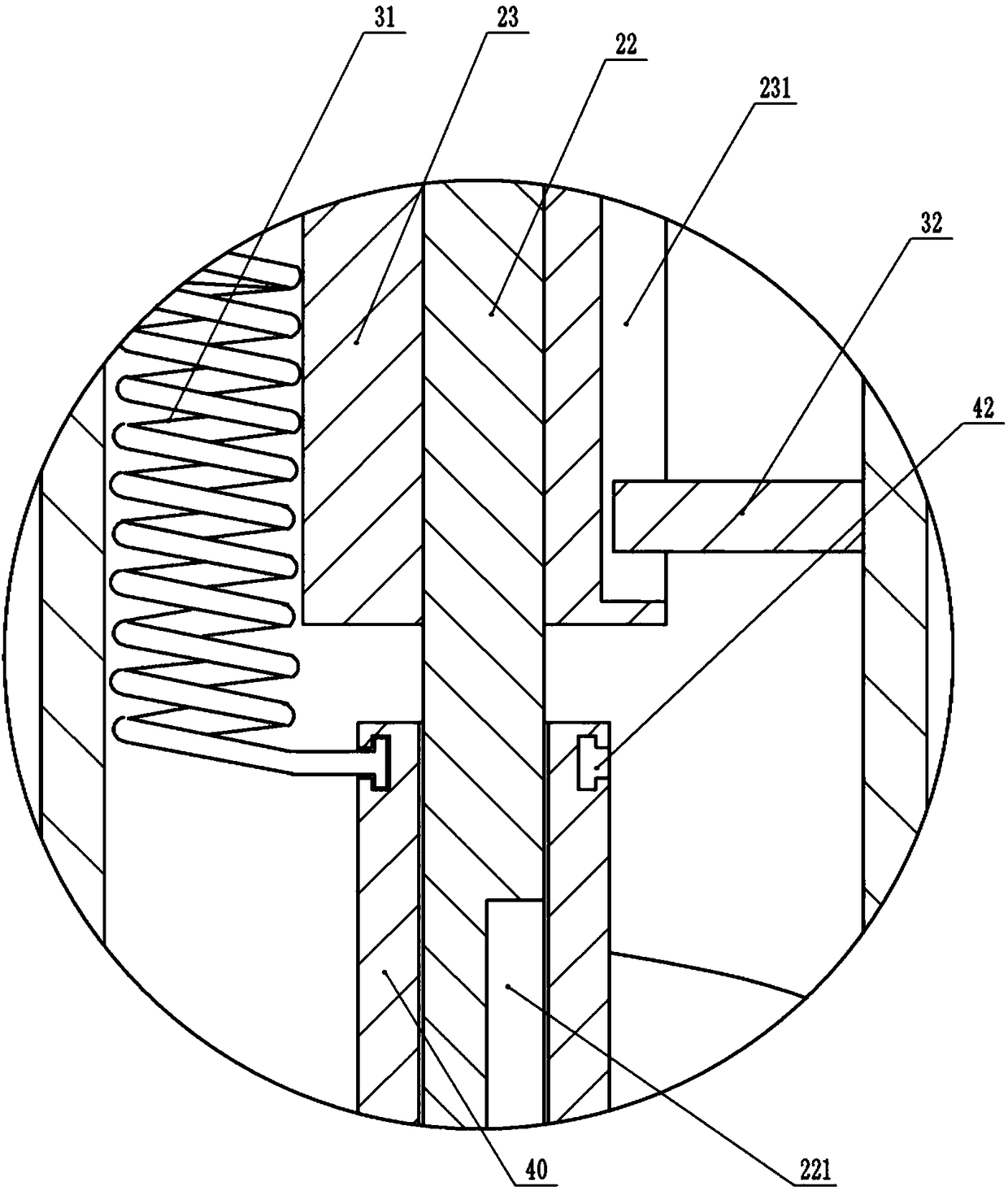

[0021] Instructions attached Figures 1 to 2 The reference signs in include: mobile trolley 10, vehicle frame 11, hopper 12, connecting rod 13, retaining cylinder 14, motor 20, belt 21, rotating shaft 22, strip groove 221, push column 23, chute 231, cylinder Body 30, tension spring 31, limit rod 32, feed pipe 33, screw-in rod 40, spiral blade 41, annular groove 42, clip 43, rotating column 50, space curve protrusion 51, cavity 52, discharge tray 53. Stirring shaft 54, curved groove 55, mixing cylinder 60, spring 61, piston cylinder 70, one-way discharge valve 71, one-way feeding valve 72, plunger 73, sieve plate 80, top column 81.

[0022] Such as figure 1 , figure 2 As shown, the digging machine used for planting fruit trees includes a mixing unit, an excavating unit and a mobile trolley 10, and a vehicle frame 11 is fixed on the mobile trolley 10. The excavating unit includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com