Online ultrasonic cleaning machine for furnace zone of sintering furnace

A technology of ultrasonic wave and sintering furnace, which is applied in the field of washing machine, can solve the problems of production capacity impact, particle shake-off, cell production impact, etc., and achieve the effect of ensuring belt speed and reducing stretching and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

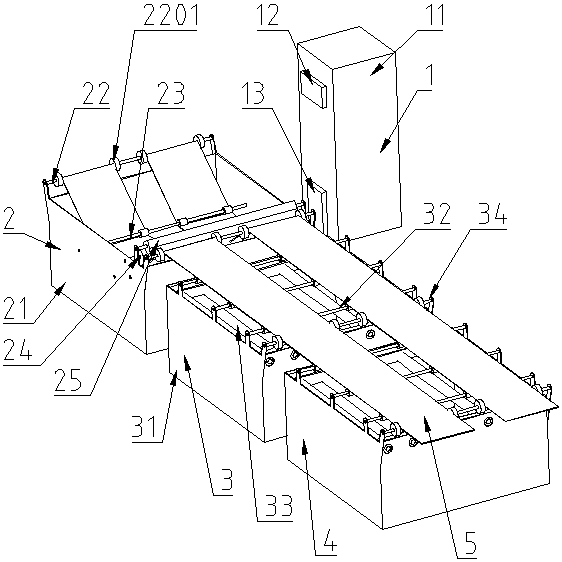

[0016] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, an ultrasonic sintering furnace belt online cleaning machine includes a control cabinet 1 and a cleaning machine 2, the control cabinet 1 includes a cabinet body 11, an ultrasonic controller 12 and a water pump 13, and the cabinet body 11 is provided with a control Components and control lines, an ultrasonic controller 12 is arranged on the front upper part of the cabinet 11, a water pump 13 is arranged on the lower part of the ultrasonic controller 12, a cleaning machine 2 is arranged on the front of the control cabinet 1, and the cleaning machine 2 includes a water tank 21, a guide roller 22, a pressing wheel 23, a cleaning roller 24, and an air knife 25. The water tank 21 is provided with a four-wheel water tank, and the four-wheel water tank is used to hold the cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com