Pyrolyzing furnace non-condensable gas collecting, pressure-stabilizing, utilizing and treating method

A treatment method and pyrolysis furnace technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., and can solve problems such as difficulty in returning non-condensable gas to the furnace, irregular gas volume, and difficulty in tail gas treatment. , to achieve the effect of solving the difficulty of exhaust gas treatment, high degree of safety design and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

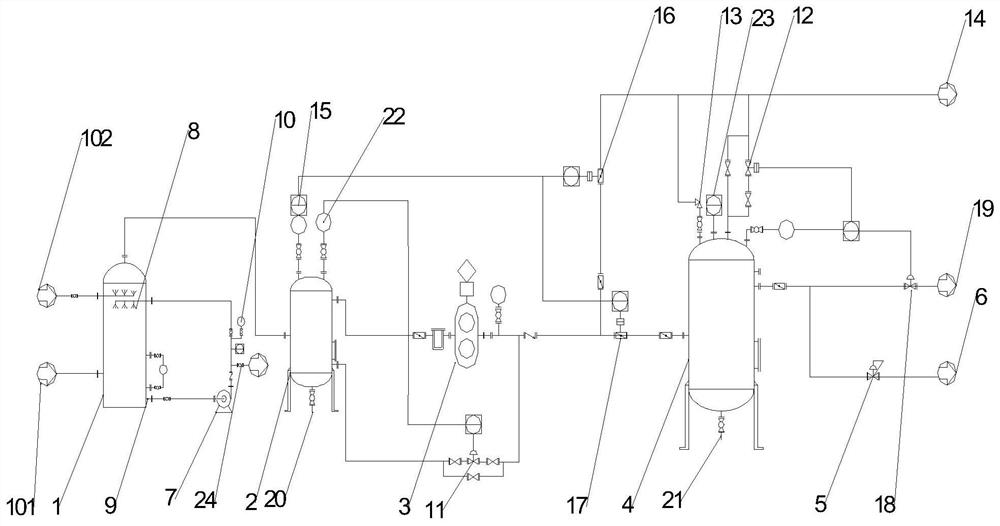

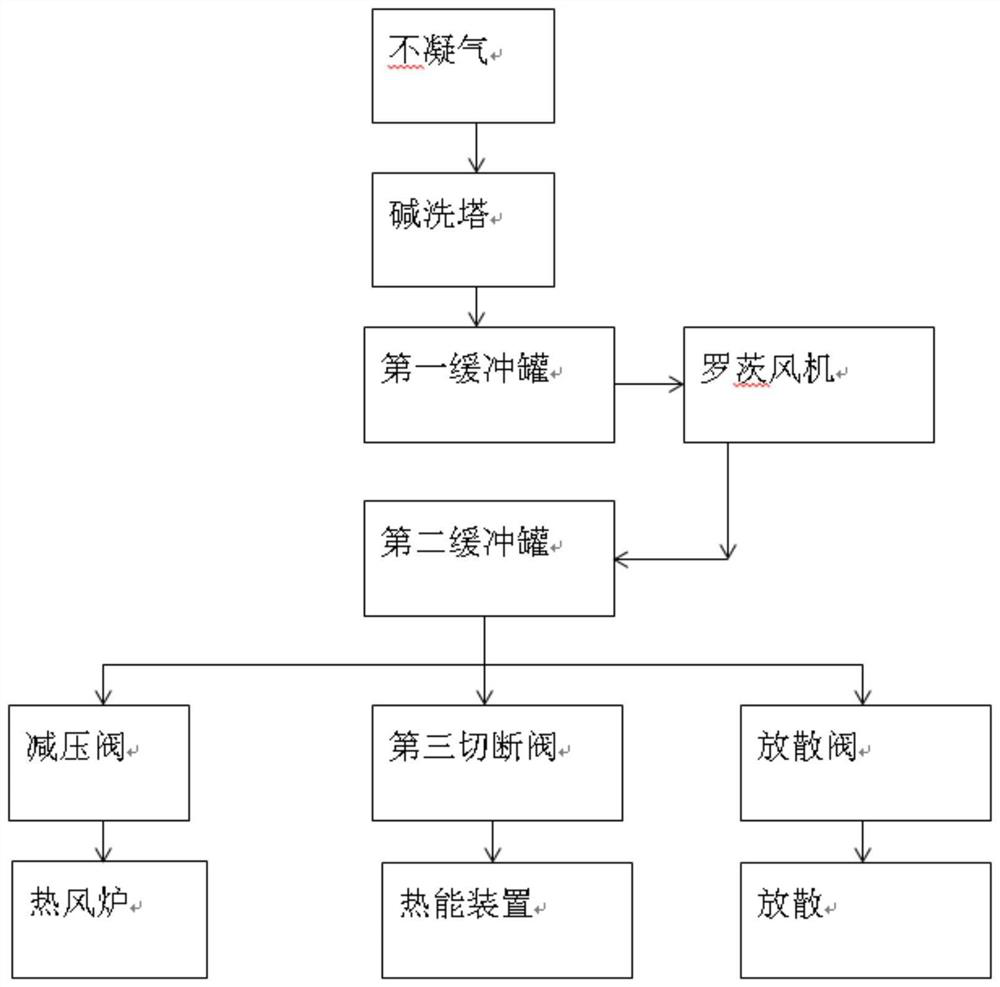

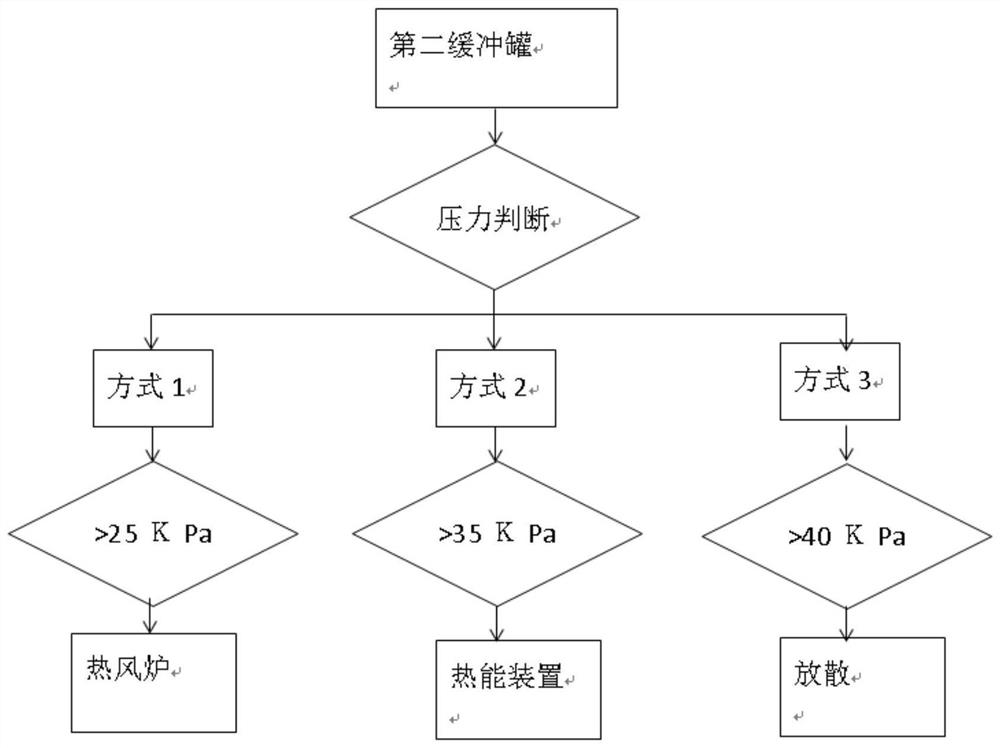

[0018] The present invention is described further in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, the working process of a system for collecting and stabilizing the non-condensable gas of the pyrolysis furnace is as follows: first, the non-condensable gas is washed with alkali to remove acid, and the non-condensable gas generated by the pyrolysis process enters the alkali-wash tower, and is sprayed by alkali-wash The pump circulates and sprays the lye to remove the acid gas in the non-condensable gas. During the cyclic spraying process, an online pH meter is used to detect the concentration of the lye. When the pH value of the lye is 12, close the waste liquid valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com