Movable rubber belt conveyor

A belt conveyor, mobile technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unstable transportation, uneven feeding, heavy weight and power, etc., to achieve flexible and light movement and adjustment, The effect of high stability and reliability and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

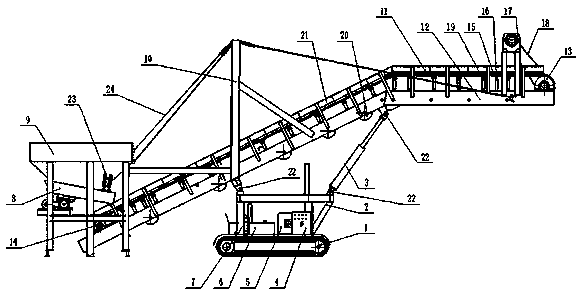

[0019] like Figure 1~2 As shown, the present invention provides a kind of mobile belt conveyor, comprises belt conveyor 11, running gear 1 and vibrating feeder 8, and described belt conveyor 11 comprises horizontal section and the inclined section that is connected in the tail of horizontal section, A support platform 2 is arranged above the traveling mechanism 1, and the front end of the support platform 2 is connected to a hydraulic cylinder 3 through a pin 22, and the top of the piston rod of the hydraulic cylinder 3 is connected to the inclined section of the belt conveyor 11 through a pin 22. Below the top, the rear end of the support platform 2 is connected with a cable-stayed support 10 through a pin shaft 22, a hopper 9 is connected above the tail of the inclined section of the belt conveyor 11, and the vibrating feeder 8 is connected through a spring 23 Below the hopper 9, and the discharge port of the vibrating feeder 8 is located above the material guide trough 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com