A grouting method for underwater large-diameter bored piles in corrosion geology

A large-diameter, bored pile technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as the difficulty in meeting the construction requirements of large-diameter bored piles, and the difficulty in further ensuring the stability of the main tower of the bridge. Conveying stability, good forming effect, uniform and stable conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

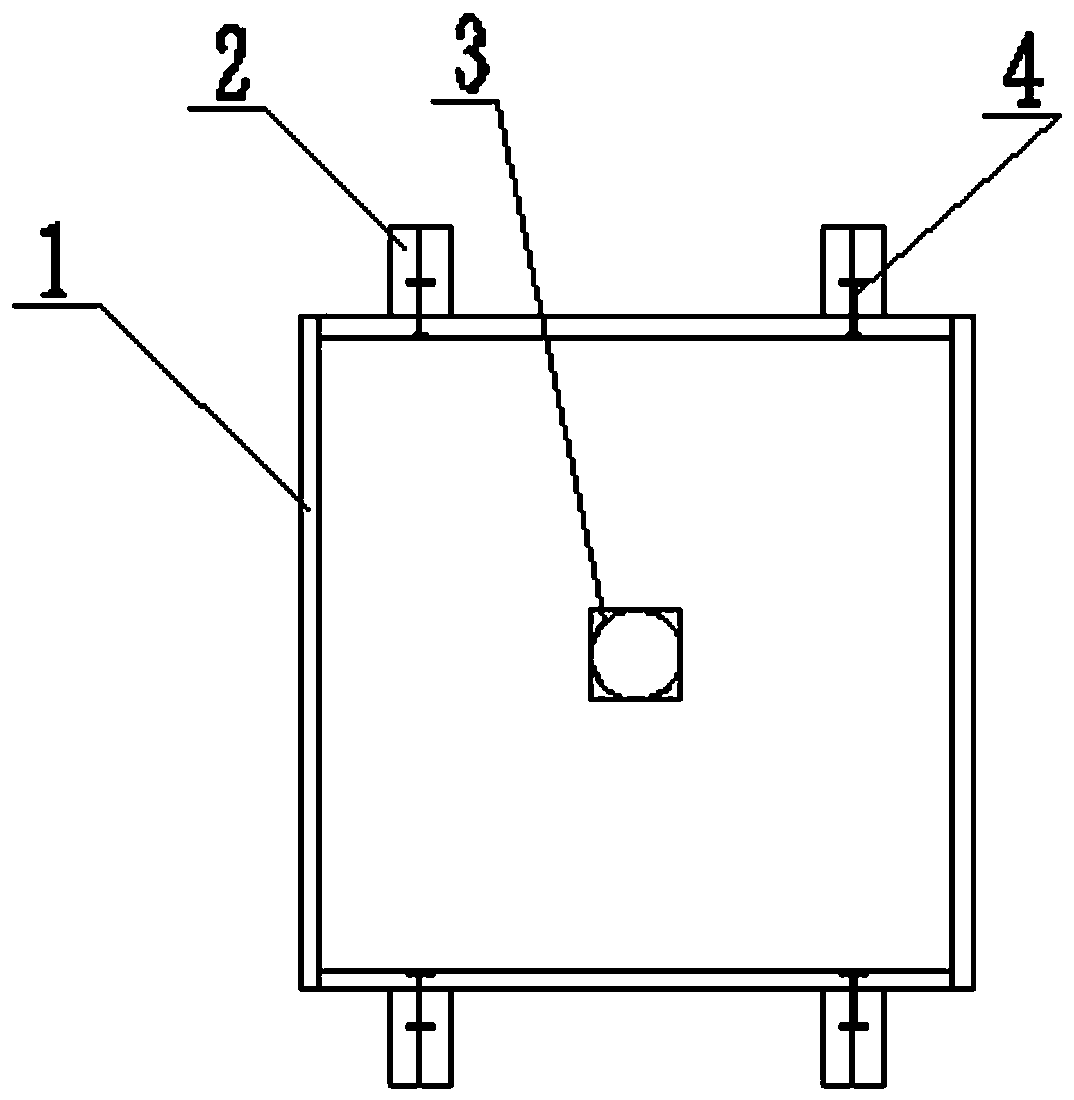

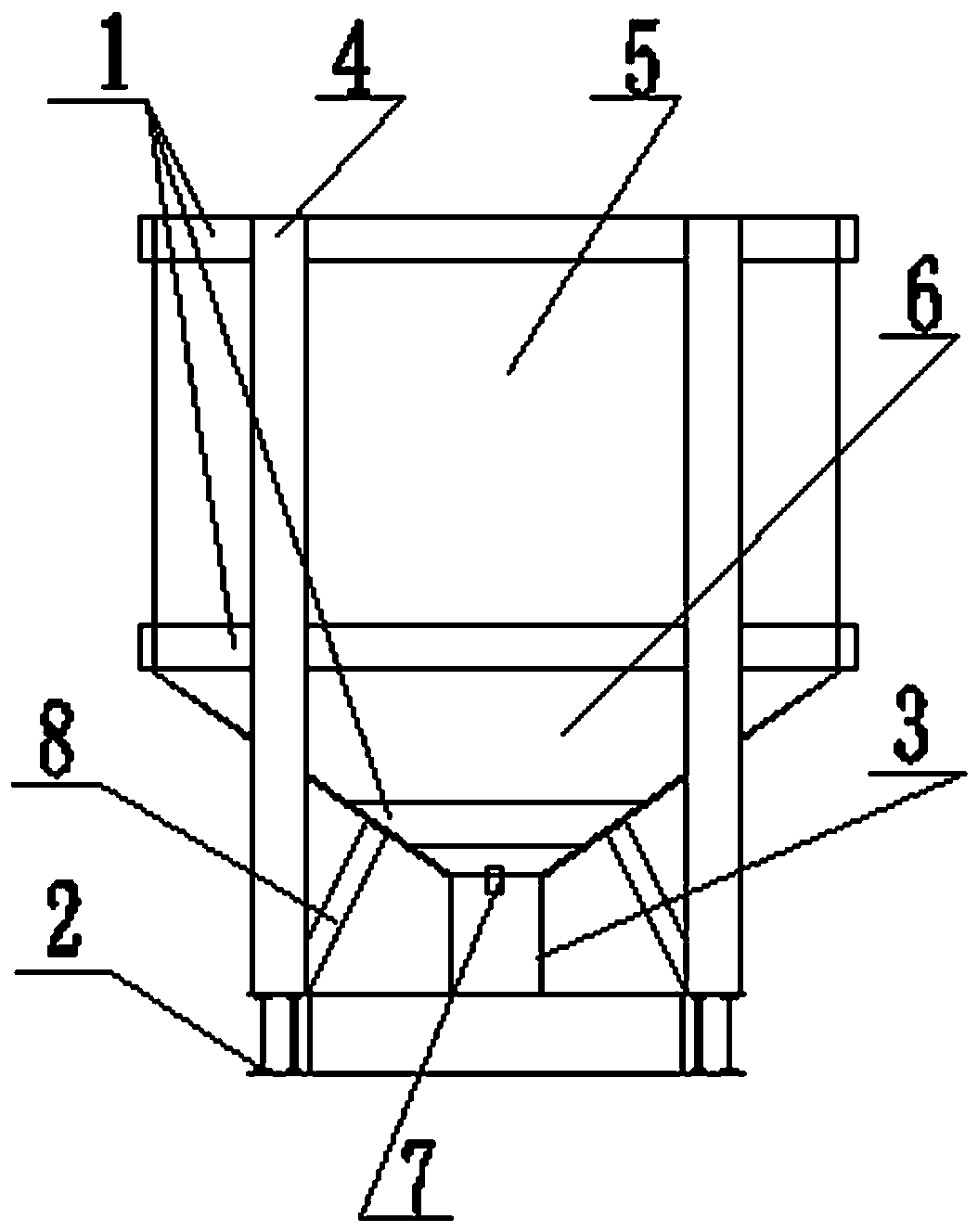

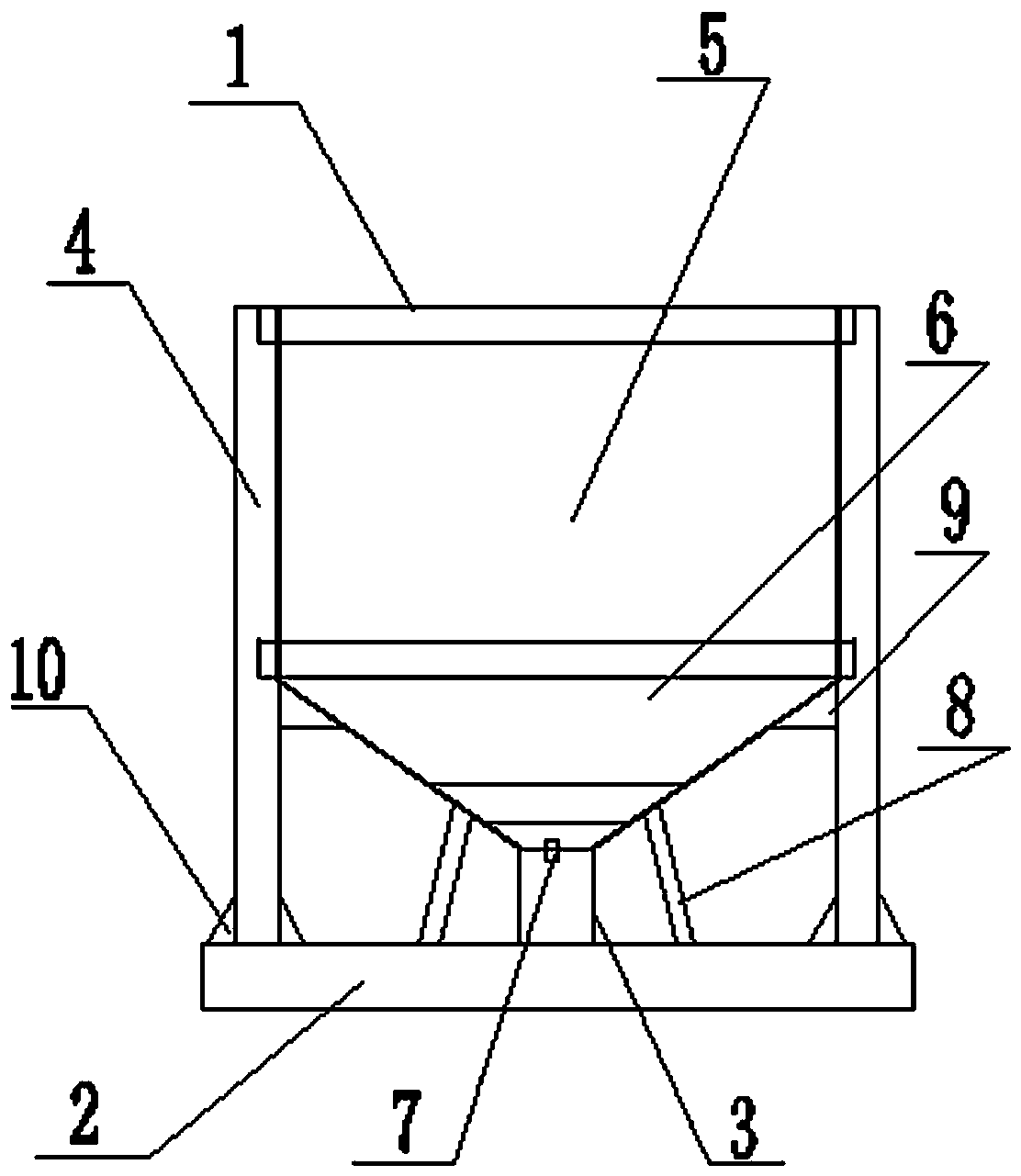

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

[0029] A pouring method for underwater large-diameter bored piles in dissolved geology, comprising the following steps:

[0030] (1) Hole opening: Insert steel casing at the pile position; prepare enough mud, inject mud into the hole of steel casing with mud pump before drilling, then add clay block, and repeat with small stroke with impact cross drill bit Impact the pile position to make slurry, so that the hole wall is solid;

[0031] (2) Drilling into the hole: remove slag in time during the drilling process; mud circulation system is used for slag removal. After the mud is prepared, it enters the mud pool and is sent into the drilled pile, and then circulates out of the drilled hole with drilling slag. The mud and drilling slag pass through the mud separator to separate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com