Laminar flow type adjustable air guide device

An air guide device, adjustable technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

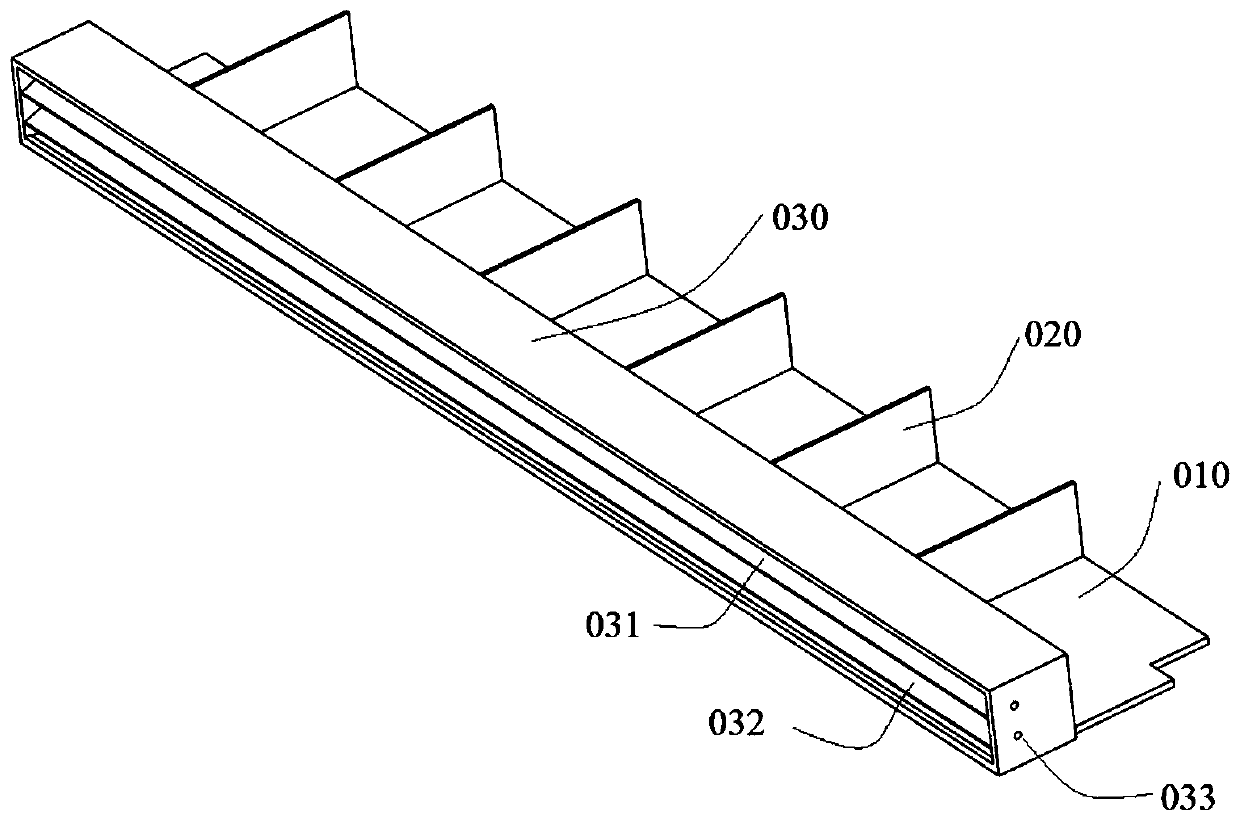

[0025] Such as figure 1 As shown, a laminar flow adjustable air deflector includes an air deflector bottom plate 010, an elongated splitter plate 020, an air deflector shell 030, an adjustable upper deflector 031, and an adjustable lower deflector 032 , Deflector fixing bolt 033.

[0026] The front end of the bottom of the air guide device housing 030 is provided with an air guide device base plate 010, and the lengthened diverter plate 020 is evenly distributed on the air guide device base plate 010. Plate 031 and adjustable lower deflector 032.

[0027] The base plate 010 of the air guiding device is used to embed and fix the air guiding device and the original air outlet, so as to ensure that the air flow smoothly enters the air guiding device from the air supply duct. Its size matches the air supply duct and the molding cavity.

[0028] The exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com