Recyclable particle jet descaling device

A technology of circulating particles and particles, which is applied in the field of recyclable particle spraying derusting devices, can solve the problems of low efficiency of manual derusting, harsh working environment for workers, and difficulty in removing oxide layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

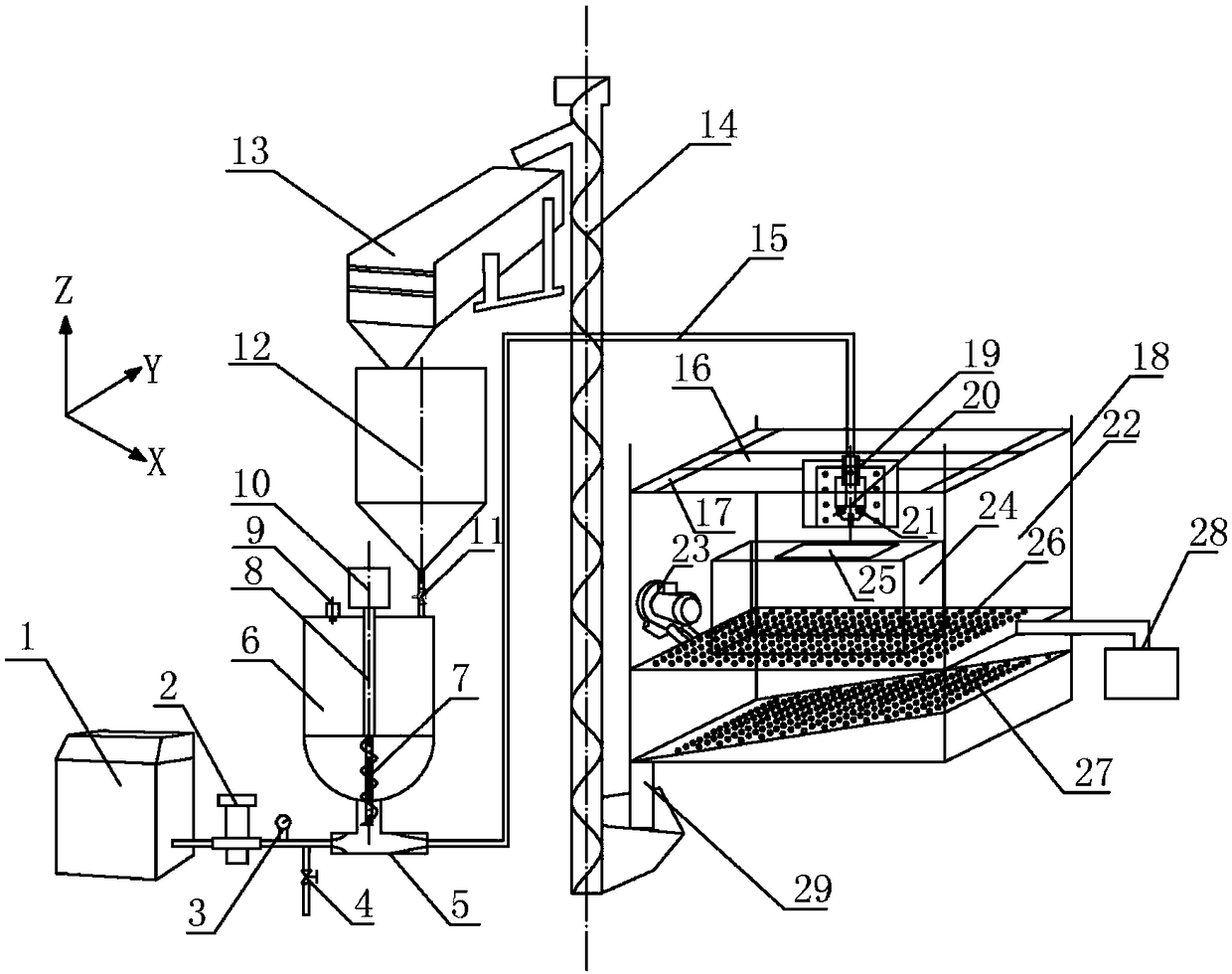

[0021] The present invention will be further described below in conjunction with accompanying drawing:

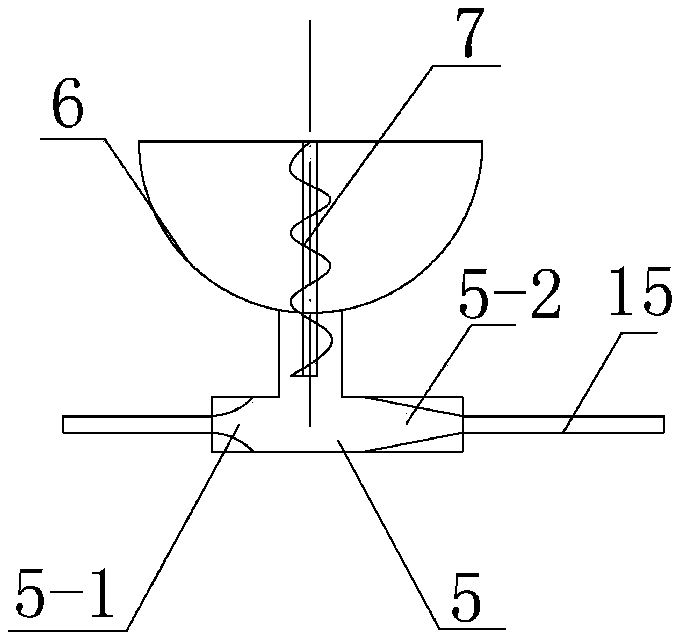

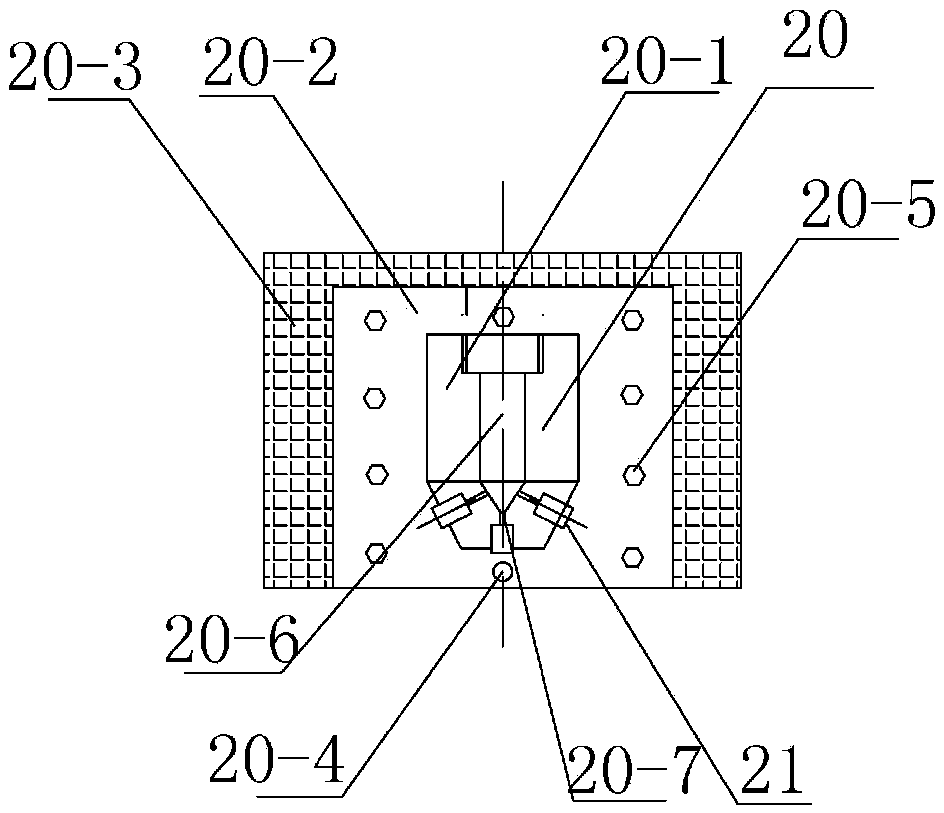

[0022] Such as figure 1 As shown, the recyclable particle spray rust removal device of the present invention includes an air compressor 1, a filter 2, a pressure gauge 3, a partial pressure valve 4, a mixing chamber 5, a high-pressure particle tank 6, a screw 7, and a screw connecting shaft 8. 3D particle amount detector 9. Speed regulating motor 10. High-pressure valve 11. Particle storage tank 12. Double-layer vibrating screen 13. Vertical screw conveyor 14. High-pressure hose 15. X-direction track 16, Y-direction track 17, Z-direction track 18, transition joint 19, nozzle assembly 20, nozzle 21, dust cover 22, blower 23, support frame 24, workpiece 25, horizontal filter orifice plate 26, inclined filter orifice plate 27, dust bag 28, particle collection Exit 29. After the air is pressurized by the air compressor 1, it is sent to the filter 2 through the hard pipe. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com