Safety drill chuck

A drill chuck, a safe technology, applied in drilling tool accessories, tool joints, drilling/drilling equipment, etc., can solve the problem that the nut sleeve and the nut are prone to relative sliding, cannot effectively adjust the jaws, and the drill bit falls off and fly out. and other problems to achieve the effect of preventing slippage, uniform and stable torque transmission, and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

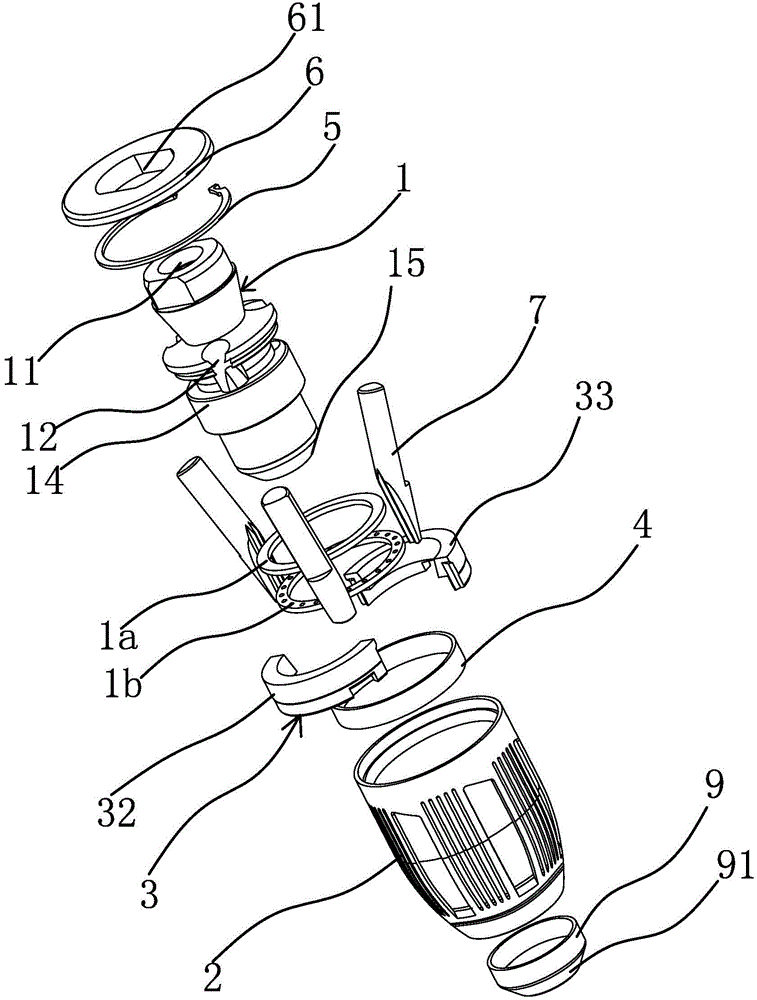

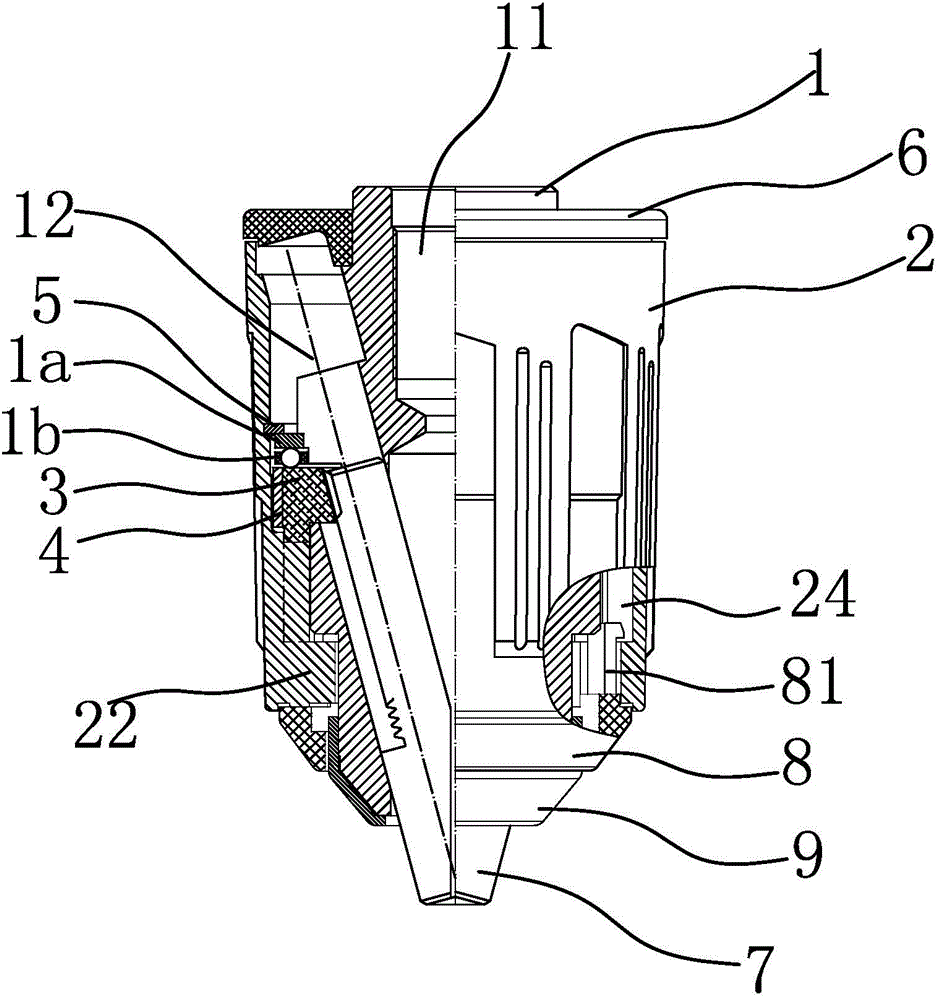

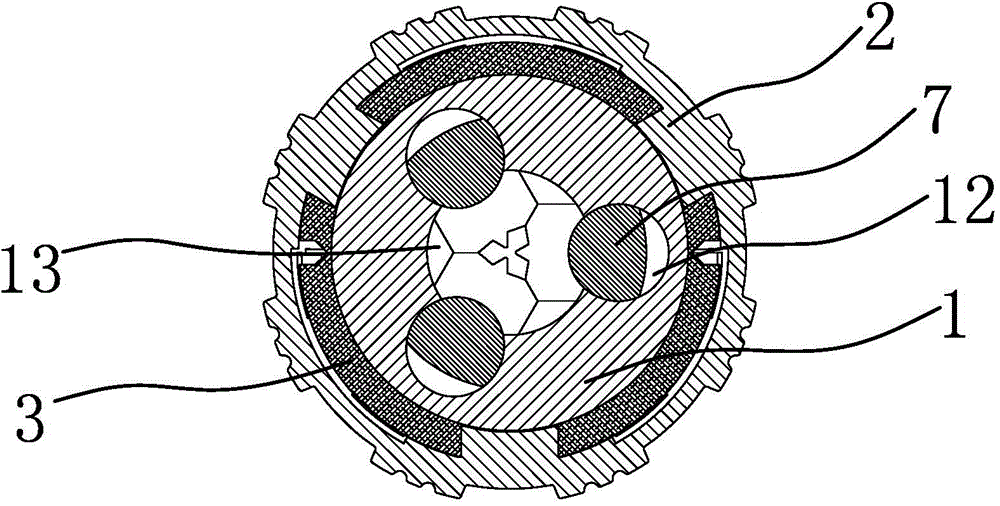

[0032] Such as Figure 1 to Figure 6As shown, the safety drill chuck includes a drill jacket 2 and a columnar drill body 1. The drill jacket 2 is sleeved on the drill body 1 and can rotate around the drill body 1. A slideway 12 inclined toward the lower end of the drill body 1, the slideway 12 is a chute or a slanted hole, in this example, a chute is used, and each slideway 12 is provided with a jaw that can slide in the slideway 12 7. There is an incomplete external thread on the jaw 7. The external thread is located on one side of the jaw 7 and matches the internal thread of the nut 3. There is also a joint between the drill chuck 2 and the jaw 7. The nut 3 is screwed together, the lower end surface of the nut 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com