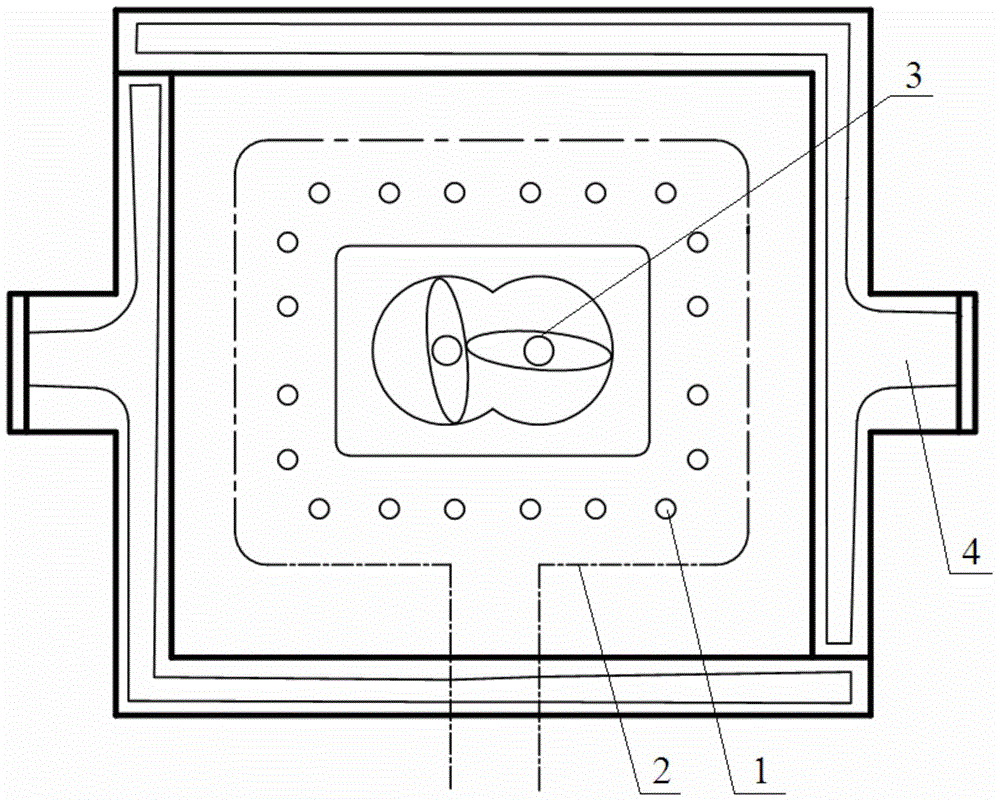

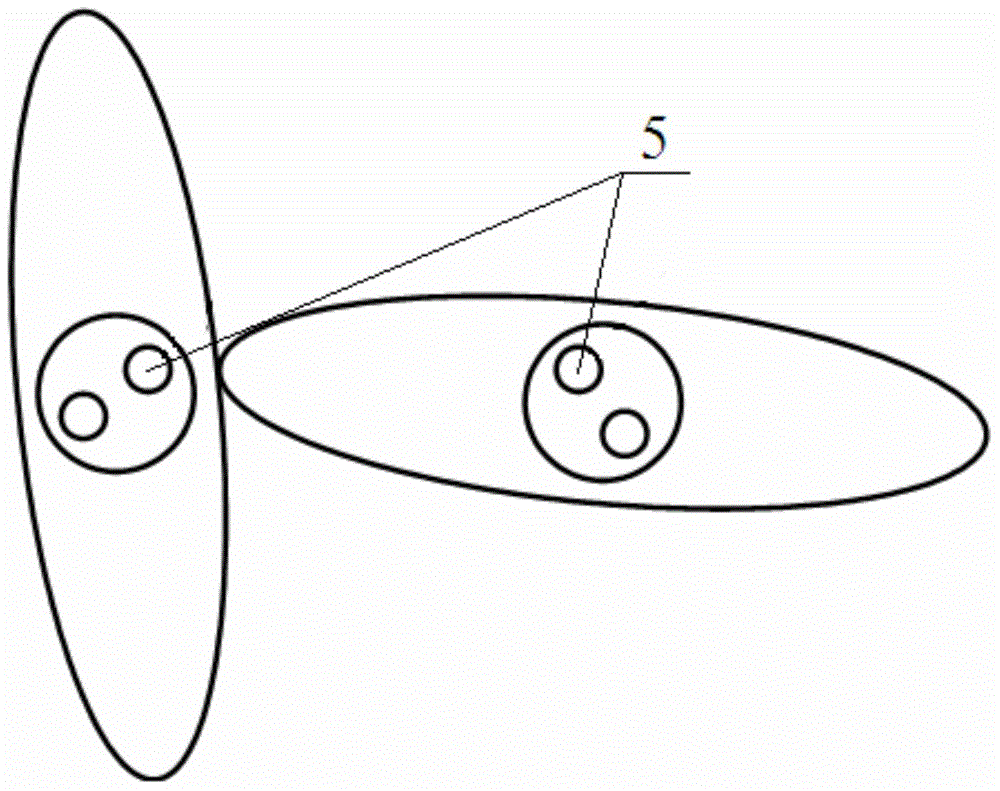

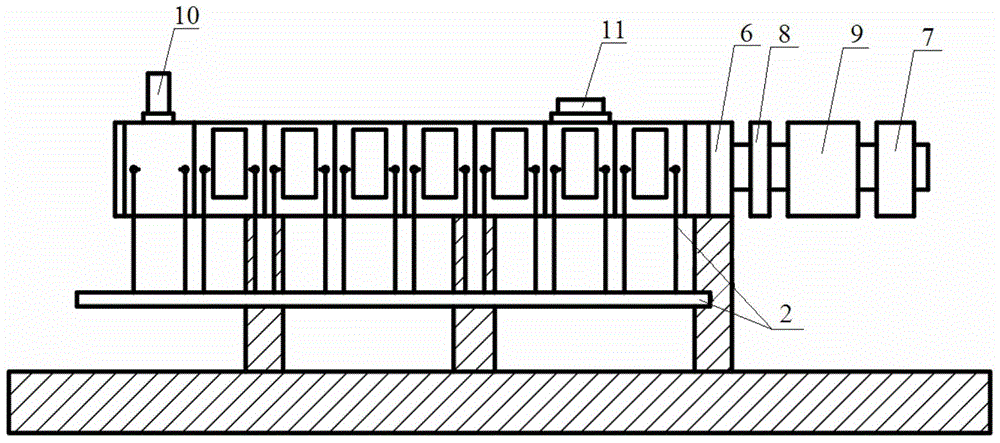

Double-screw extruder for producing polyolefin pipe and production process thereof

A twin-screw extruder and extruder technology, which is applied in the field of plastic pipe production, can solve the problems of failing to meet the minimum pressure requirements for pipe forming, the life of the pipe cannot meet the needs of use, and the temperature of the raw material melt. Low cost and the effect of increasing die pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Mixing. Configure materials in the following proportions:

[0024]

[0025] Put the above materials into a high-speed stirrer and mix evenly, the speed of the stirrer is 800r / min, and the stirring time is 10min.

[0026] (2) Add the uniformly mixed materials into the twin-screw extruder of the present invention, the extruder screw diameter is 75 mm, and the screw speed is 350 r / min.

[0027] (3) Pass 20°C water into the cooling channel of the twin-screw mandrel to cool the screw, so as to reduce the temperature of the material and prevent the material from degrading and destroying under the condition of high-speed shearing and heating.

[0028] (4) Use the combination of air cooling and water cooling to precisely control the temperature of the barrel, and keep the temperature of the barrel at 190-220°C;

[0029] (5) Install a filter screen between the extruder head and the pipe die to increase the back pressure of the extruder and promote the melting and plasti...

Embodiment 2

[0034] (1) Mixing. Configure materials in the following proportions:

[0035]

[0036] Put the above materials into a high-speed stirrer and mix evenly, the speed of the stirrer is 800r / min, and the stirring time is 10min.

[0037] (2) Put the uniformly mixed materials above into a parallel twin-screw extruder with a screw diameter of 75mm and a screw speed of 350r / min.

[0038] (3) Pass 23°C water into the cooling channel of the twin-screw mandrel to cool the screw, so as to reduce the temperature of the material and prevent the material from degrading and destroying under the condition of high-speed shearing and heating.

[0039] (4) Use the combination of air cooling and water cooling to precisely control the temperature of the barrel, and keep the temperature of the barrel at 190-220°C;

[0040] (5) Install a filter screen between the extruder head and the pipe die to increase the back pressure of the extruder and promote the melting and plasticization of raw material...

Embodiment 3

[0045] (1) Mixing. Configure materials in the following proportions:

[0046]

[0047] Put the above materials into a high-speed stirrer and mix evenly, the speed of the stirrer is 800r / min, and the stirring time is 10min.

[0048] (2) Put the uniformly mixed materials above into a parallel twin-screw extruder with a screw diameter of 75mm and a screw speed of 350r / min.

[0049] (3) Put 30-40°C oil into the cooling channel of the twin-screw mandrel to cool the screw, so as to reduce the temperature of the material and prevent the material from degrading and destroying under the condition of high-speed shearing and heating.

[0050](4) Use the combination of air cooling and water cooling to precisely control the temperature of the barrel, and keep the temperature of the barrel at 190-220°C;

[0051] (5) Install a filter screen between the extruder head and the pipe die to increase the back pressure of the extruder and promote the melting and plasticization of raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com